Method and system for evaluating performance of power supply system of automobile

A technology for power supply systems and automobiles, applied in electric vehicles, current collectors, power supply testing, etc., can solve problems such as disadvantages, shorten development cycles, and cannot create induced or simulated application environments, and achieve the effect of enhancing functions and reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Hereinafter, the present invention will be specifically described based on the drawings showing the embodiments of the present invention.

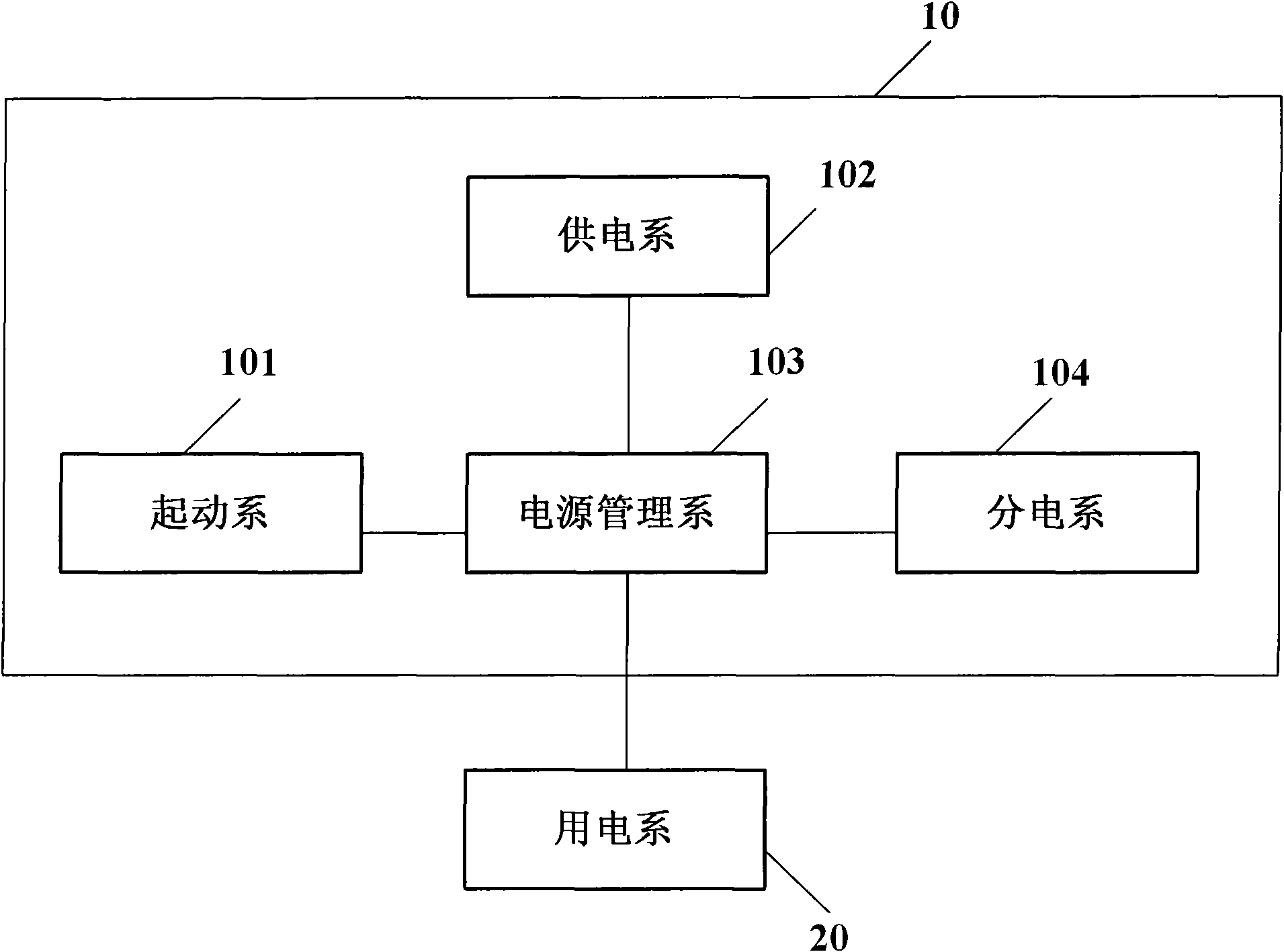

[0030] figure 1 A schematic diagram of the architecture of a typical automotive power supply system. Such as figure 1 As shown, the vehicle power supply system 10 includes a starting system 101 , a power supply system 102 , a power management system 103 and a power distribution system 104 . The starting system 101 refers to a starter. The power supply system 102 is also called the charging system, including storage batteries and generators, which convert chemical energy and mechanical energy into electrical energy, and supply them to the starting system 101 and the power consumption system 20 (that is, the collection of energy-absorbing components, such as air conditioners, igniters, etc.) ) output power. The power management system 103 is used for coordinating the management and supply of electric energy, so as to achieve the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com