Copper-zinc alloy electroplating bath and method of plating using same

A zinc alloy and compound technology, applied in thin material processing, transportation and packaging, etc., can solve the problems of high toxicity and heavy burden of cyanide-containing waste liquid treatment, etc., and achieve the effect of reducing surface roughness parameters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Hereinafter, preferred embodiments of the present invention will be described in detail.

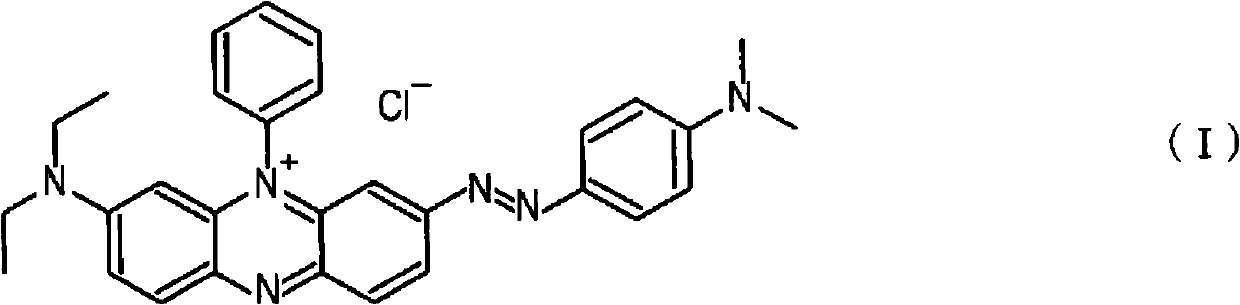

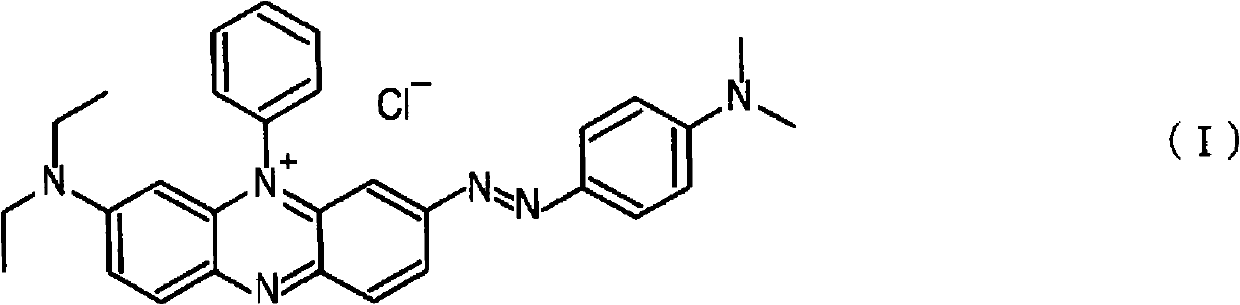

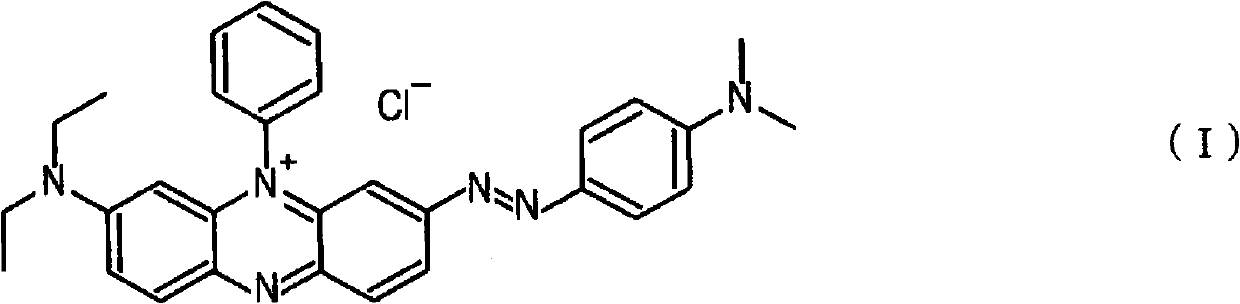

[0025] It is important that the copper-zinc alloy electroplating bath of the present invention contains at least one compound in the compound shown in following formula (I)~(III) as additive:

[0026]

[0027] R 2 -O-(R 1 -O) n -R 2 (II)

[0028] (Here, R 1 For lower alkylene, R 2 Is H or lower alkyl, weight average molecular weight is 10 3 ~10 5 . )

[0029] (Hereafter also referred to as "polyoxyalkylene derivative".)

[0030] Na-SO 3 -(CH 2 ) 3 -S-S-(CH 2 ) 3 -SO 3 -Na(III)

[0031] (bis(3-sulfopropyl)disodium disulphide, hereinafter also referred to as "SPS"). By using JGB, polyoxyalkylene derivatives or SPS as additives in the copper-zinc alloy electroplating bath, the spreading ability of the copper-zinc alloy plating film can be improved. In addition, as a polyoxyalkylene derivative, polyethylene glycol can be used preferably, for exa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com