Method and device for eliminating spiral roll marks on steel strip surface finishing machine

A skin pass mill and strip elimination technology, which is applied in the field of cold rolled strip rolling, can solve the problems of high cost, achieve the effects of reducing production costs, reducing the number of roll replacements, and eliminating spiral roll marks in skin pass mills

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The invention provides a method and device for eliminating the spiral roll mark of the strip steel surface pass machine, which mainly solves the problem of the spiral roll mark defect of the strip steel pass finish machine on the continuous hot-dip galvanizing production line through a simple equipment transformation method, and the transformation is without The modification of mechanical and electrical hardware basically does not require capital investment. After the transformation is successful, there is no additional maintenance cost.

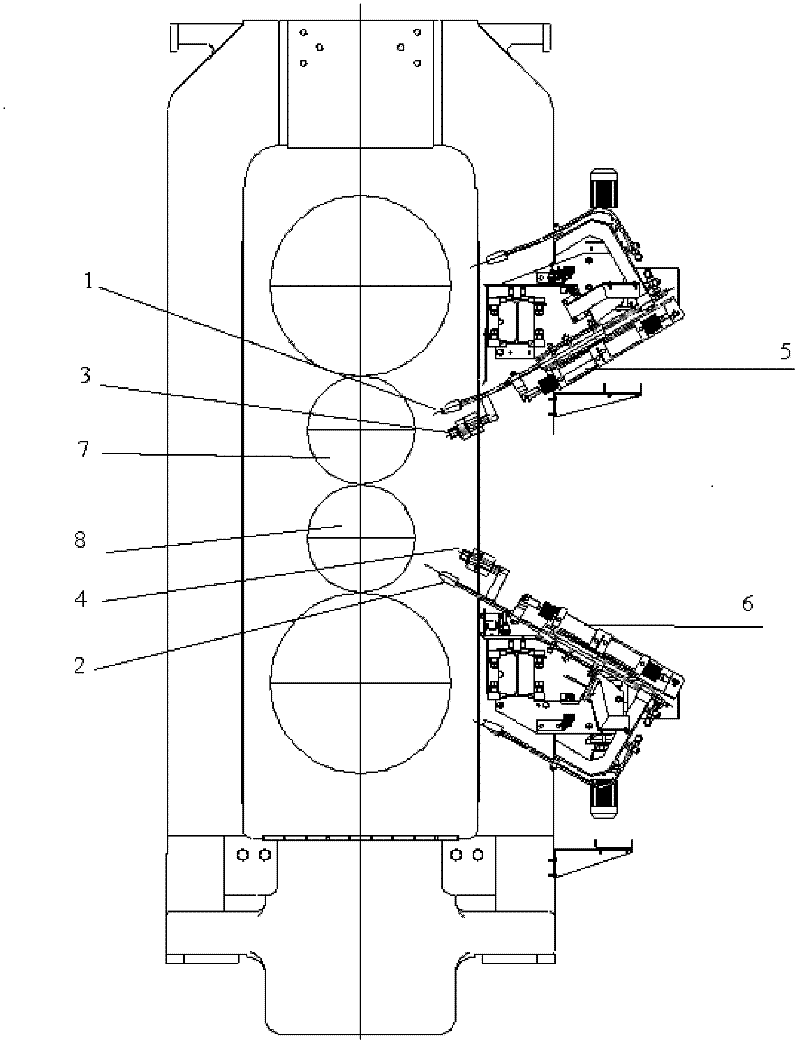

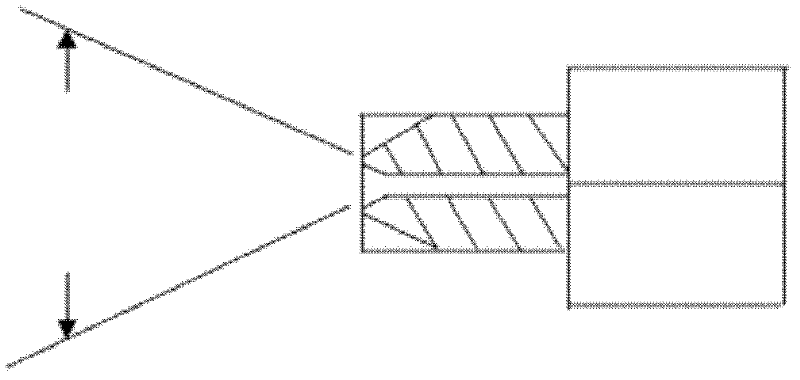

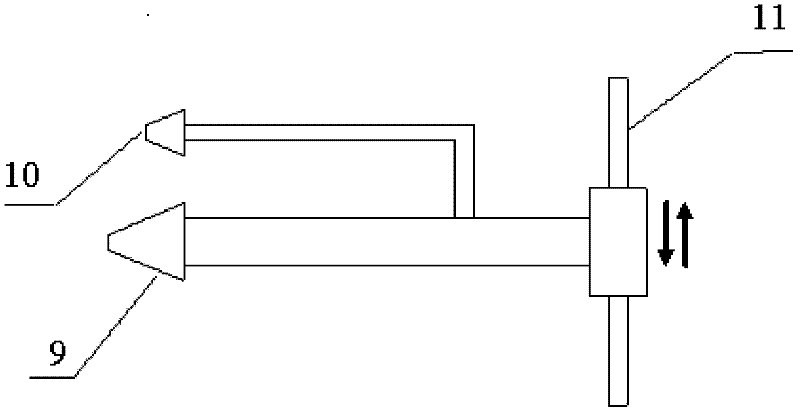

[0034] like figure 1 As shown, the device provided by the present invention for eliminating the spiral roll mark of the skin pass mill of the strip steel includes: a high pressure cleaning nozzle 9 , a flat nozzle 10 , a horizontal moving frame 11 of the nozzle and a work roll 12 of the skin pass mill. The high-pressure cleaning nozzle 9 includes an upper high-pressure cleaning nozzle 1 and a lower high-pressure cleaning nozzle 2 . T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com