Balance type cleaning machine for large-size cement silo

A cement silo and balance-type technology, which is applied in the field of balance-type warehouse cleaning machines for large cement silos, can solve problems such as inability to install circular tracks, unusable mechanical equipment, and easy sticking to the wall of the silo.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

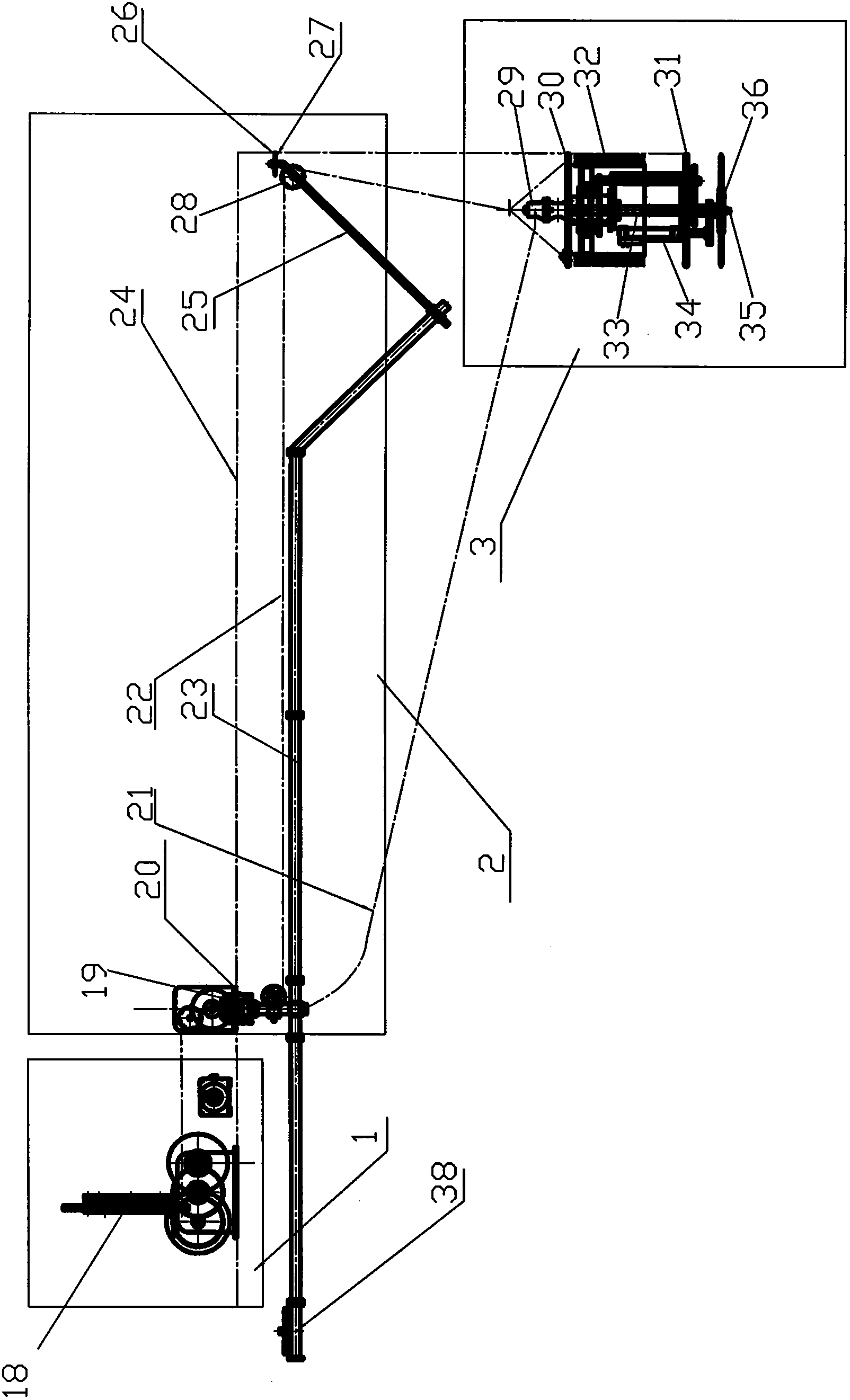

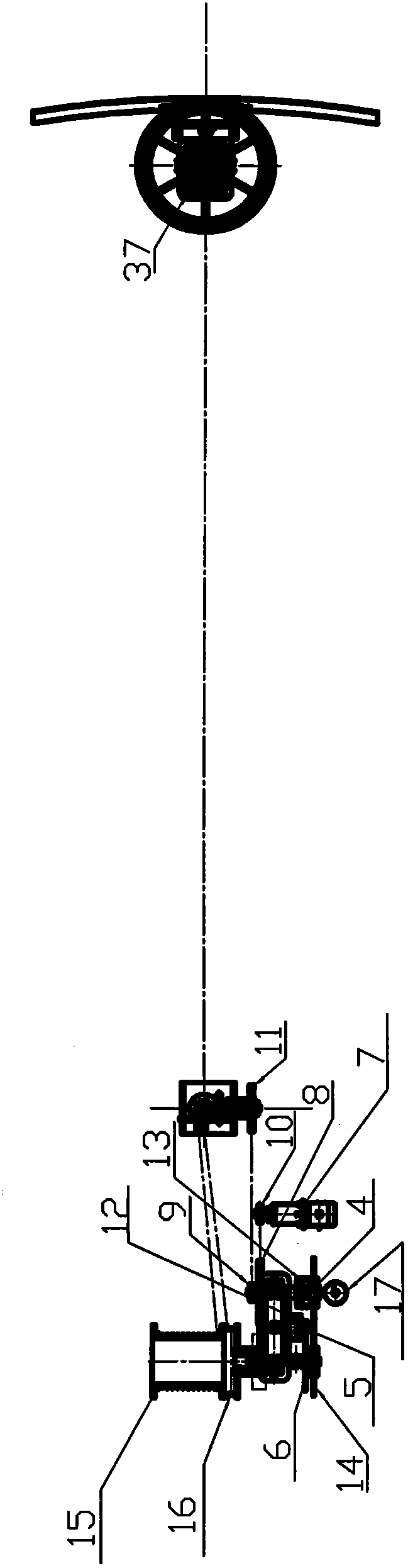

[0017] see figure 1 , figure 2 :

[0018] A balance type warehouse cleaning machine for a large cement warehouse of the present invention is composed of a main machine 1, a track rotation mechanism 2, and a warehouse cleaning mechanism 3, wherein the main machine 1 is composed of a motor 7, a reducer, a main shaft 4, an intermediate shaft 5, and a transmission shaft 6 , wire rope reel 16, trachea reel 15, clutches 12, 13, sprockets 8, 9, 10, 11, transmission chain, gear 14, height display mechanism 18, circumference display mechanism 17, and the motor 7 passes through the reducer Connect with sprocket 9, sprocket 9 is connected with main shaft 4 through transmission chain, clutch, gear 14, main shaft 4 is connected with intermediate shaft 5 through gear 14, intermediate shaft 5 is connected with transmission shaft 6 through clutch 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com