Production method and device of organic-inorganic compound fertilizer

A technology of compound fertilizer and production method, which can be applied to fertilizer forms, fertilizer mixtures, and fertilization devices, etc., can solve problems such as consuming more energy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

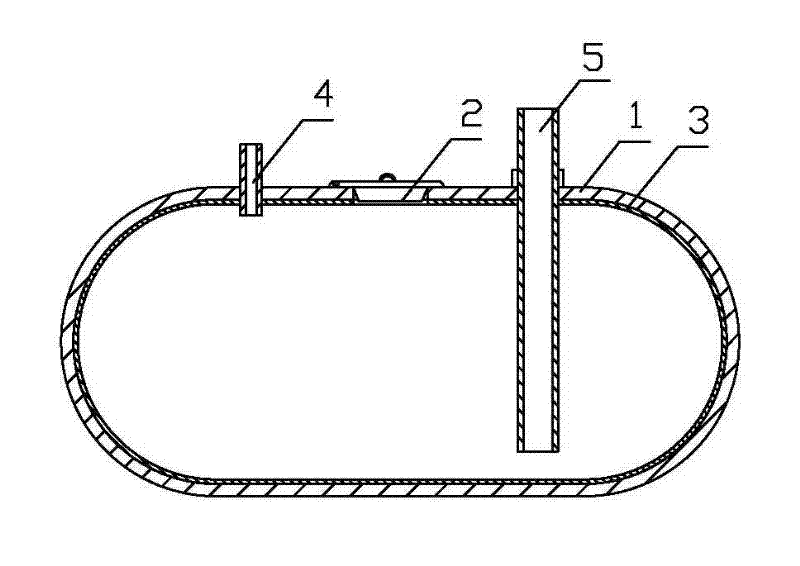

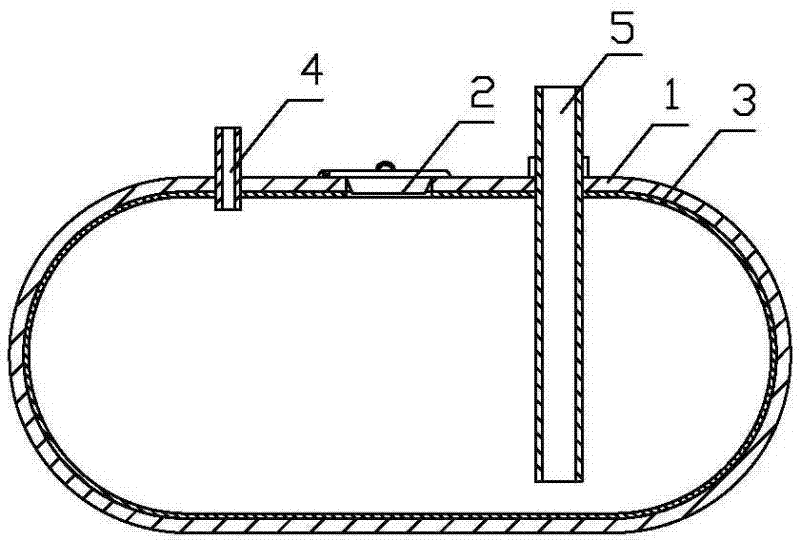

Image

Examples

Embodiment 1

[0016] A kind of production method of organic-inorganic compound fertilizer of the present invention is characterized in that comprising the steps:

[0017] Step A) prepare sulfuric acid urea mother liquor, put 15 parts of urea and equal amount of water into the sulfuric acid urea mother liquor preparation tank and mix according to the ratio in parts by weight, after the urea dissolves completely, inject 15 parts of sulfuric acid in the sulfuric acid urea mother liquor, Generate sulfuric acid urea mother liquor for subsequent use;

[0018] Step B) Prepare granule masterbatch according to the ratio of parts by weight, pulverize 30 parts of weathered coal, add 2 parts of monoammonium phosphate, 15 parts of potassium chloride, and 1 part of medium and trace element fertilizers, mix and stir evenly, and generate granule masterbatch spare material;

[0019] Step C) Send the granular masterbatch produced in step B) into the granulator, and at the same time use the spray device to s...

Embodiment 2

[0025] The parts by weight proportioning of this product raw material is:

[0026] Urea 25, water 25, sulfuric acid 25, weathered coal 35, monoammonium phosphate 30, potassium chloride 25, medium and trace element fertilizer 5;

[0027] Concrete production steps are with embodiment 1.

Embodiment 3

[0029] The parts by weight proportioning of this product raw material is:

[0030] Urea 10, water 10, sulfuric acid 20, weathered coal 35, monoammonium phosphate 25, potassium chloride 20, medium and trace element fertilizer 3;

[0031] Concrete production steps are with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com