Controller for fuel injection

A fuel injector and fuel injection technology, applied in the directions of fuel injection control, electrical control, engine control, etc., can solve the problem of not being able to control the end time of fuel injection with high accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

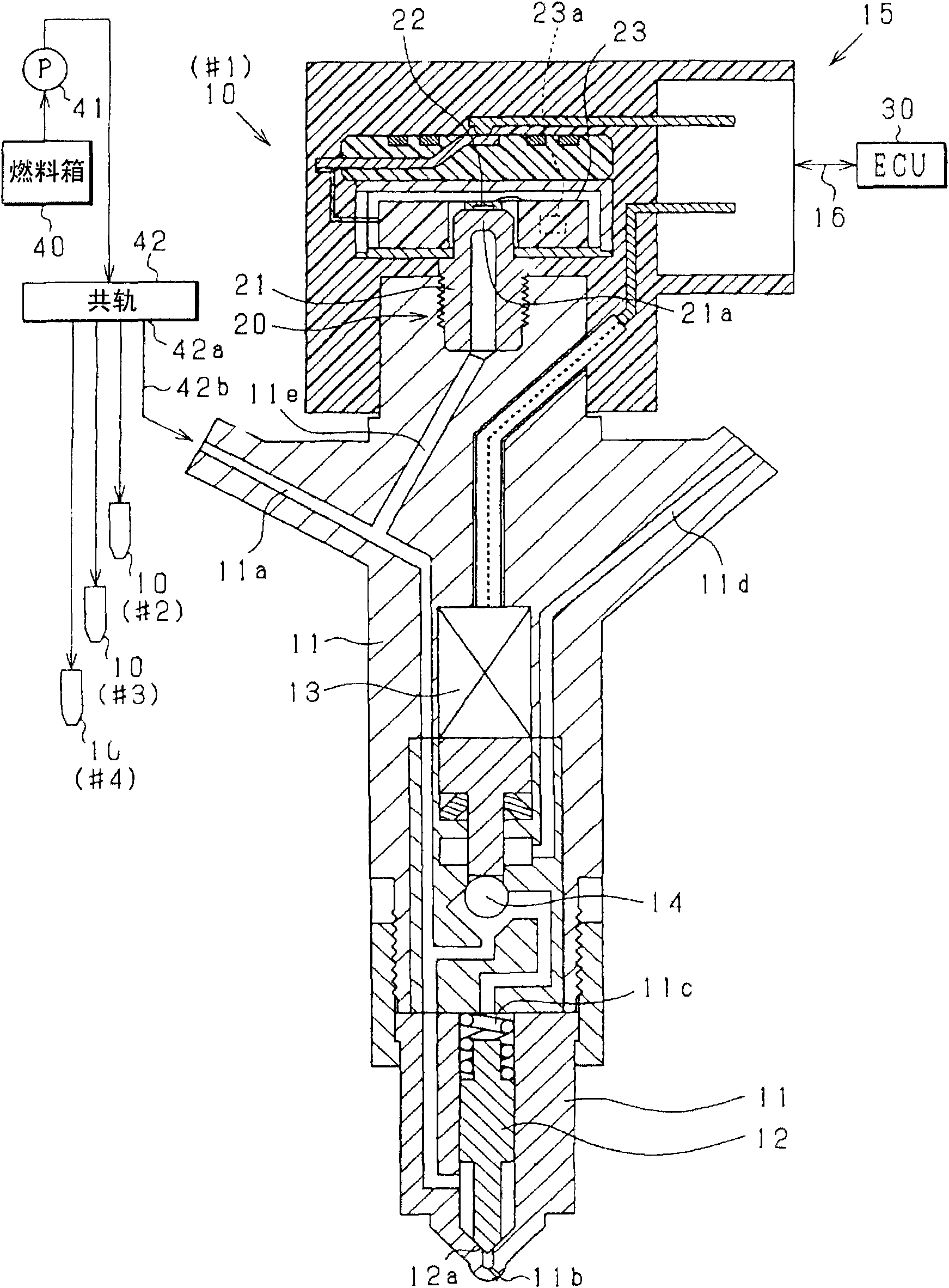

[0022] Hereinafter, an embodiment of the fuel injection state detector according to the present invention will be described. The fuel injection state detector is applied to an internal combustion engine (diesel engine) having four cylinders #1-#4.

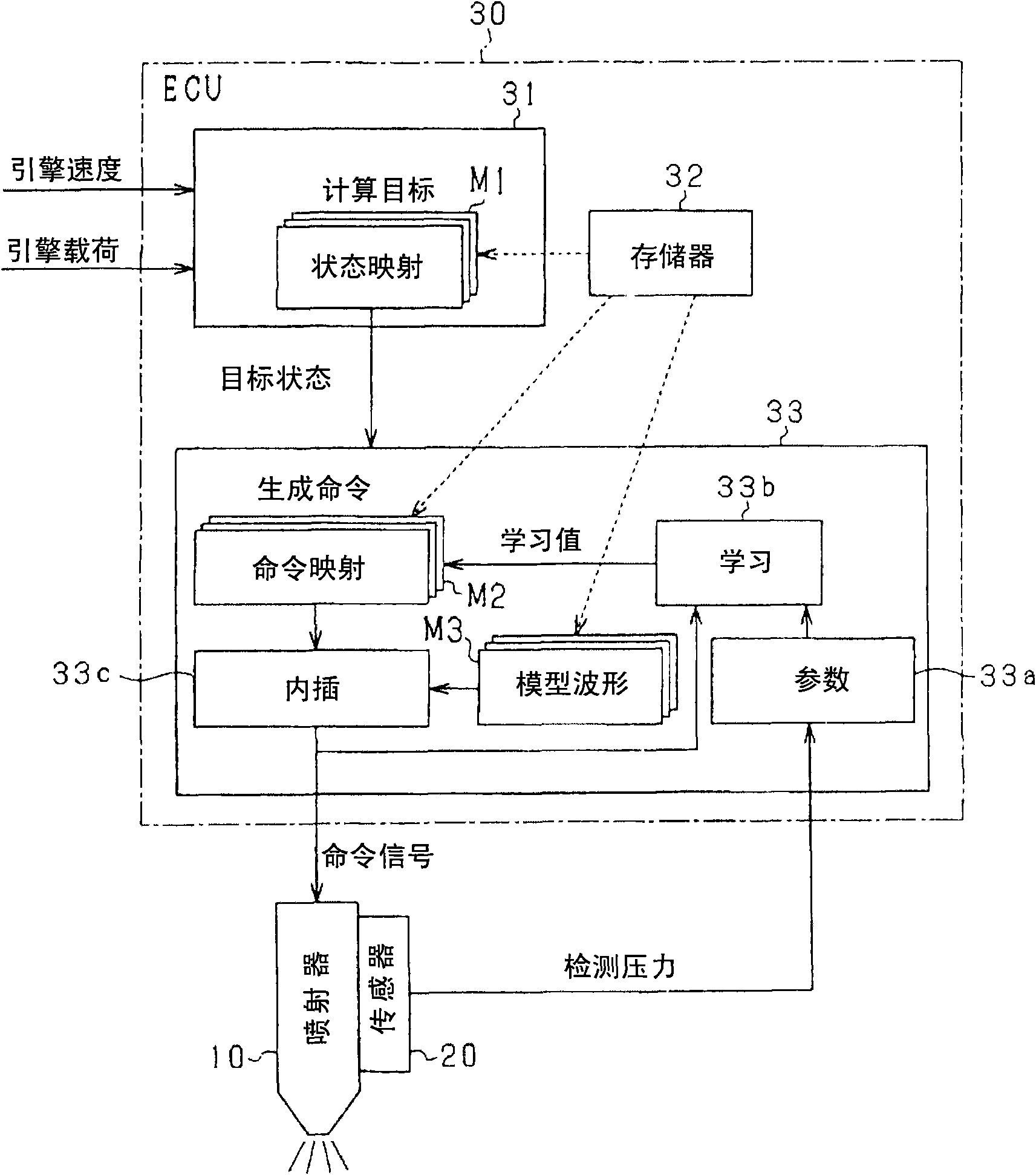

[0023] figure 1 is a schematic diagram showing a fuel injector 10 provided to each cylinder, a fuel pressure sensor 20 provided to each fuel injector, an electronic control unit (ECU) 30 , and the like.

[0024] First, the fuel injection system of the engine including the fuel injector 10 will be explained. The fuel in the fuel tank 40 is pumped by the high-pressure pump 41 and accumulated in the common rail 42 to be supplied to each fuel injector 10 (#1-#4). The fuel injectors 10 (#1-#4) sequentially perform fuel injection in a predetermined order. The high-pressure pump 41 is a piston pump that discharges high-pressure fuel intermittently.

[0025] The fuel injector 10 is composed of a main body 11, a needle valve main body ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com