Coal mine underground wet concrete injection machine monitoring system and method

A technology of concrete spraying machine and monitoring system, which is applied in earthwork drilling, fluid pressure actuating system components, wellbore lining, etc. It can solve problems such as difficult fault detection and maintenance, achieve high reliability and intelligence, and flexible system configuration , PLC is easy to use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

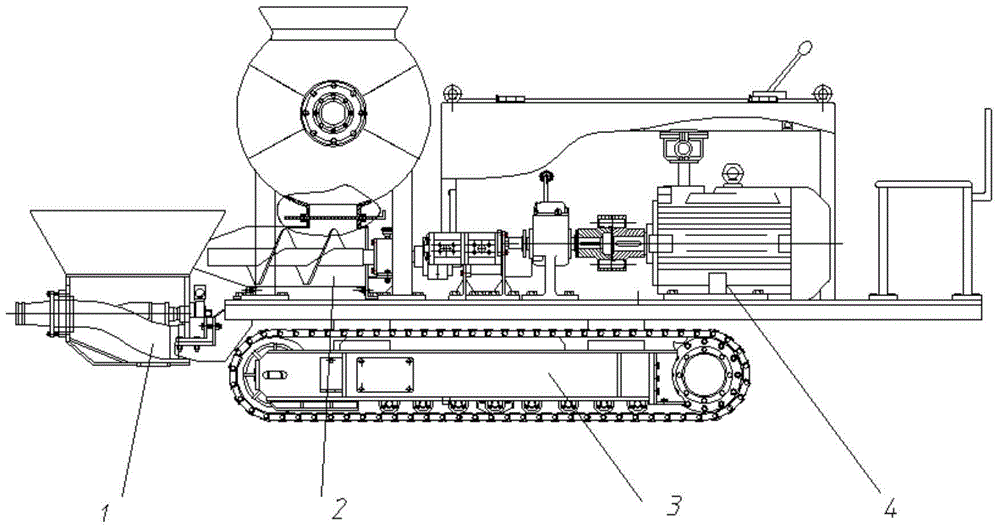

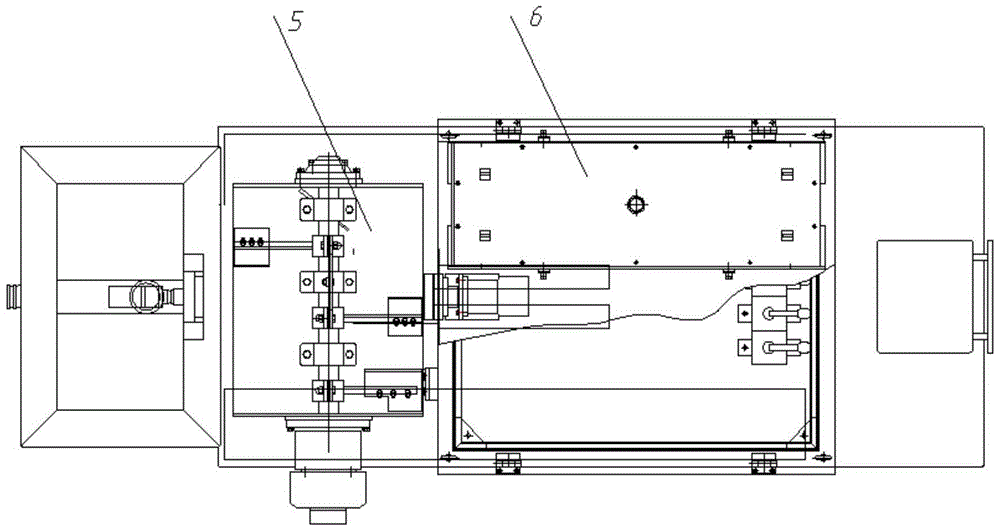

[0027] Example 1: figure 1 As shown, the main structure of the coal mine underground wet concrete sprayer of the present invention includes a pumping system 1, a screw conveying mechanism 2, a crawler walking mechanism 3, a stirring mechanism 4, an oil tank 5 and a hydraulic pump station 6; The concrete is sprayed out through the S pipe; the screw conveying mechanism conveys the wet concrete mixed by the mixing mechanism to the hopper, and at the same time, because the screw conveying blade has the stirring function, it can realize the secondary mixing of the concrete and improve the quality of the concrete; the crawler walking mechanism makes the machine It can walk quickly and freely on the narrow underground excavation surface, and realize the automatic walking of the jet machine; the mixing mechanism is a forced single-shaft mixer, which mixes fully and evenly, and strengthens the strength of the concrete.

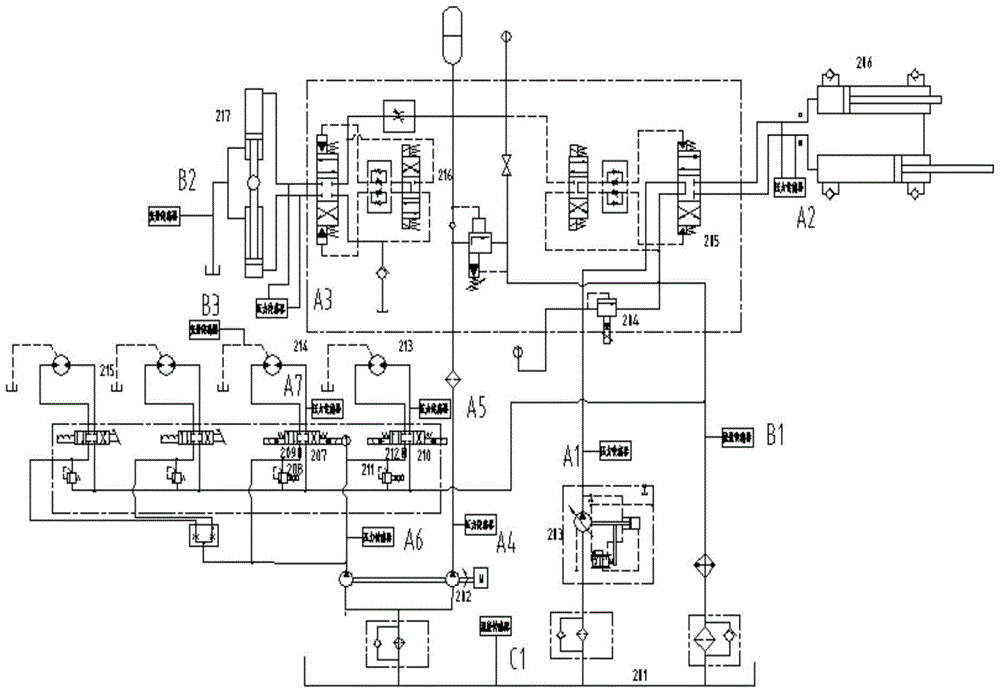

[0028] figure 2 As shown, the hydraulic system of the wet concr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com