Angle mechanically-operated controller with built-in rotary blade

A blade angle and adjuster technology, which is applied in the direction of mechanical equipment, machines/engines, non-variable pumps, etc., can solve the problem of the short distance of the drive shaft of the adjuster and the blade adjustment rod moving up and down, and the oil throwing of the adjuster , Planar bearings are easy to be damaged, etc., to shorten the rotation time and reduce mechanical wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

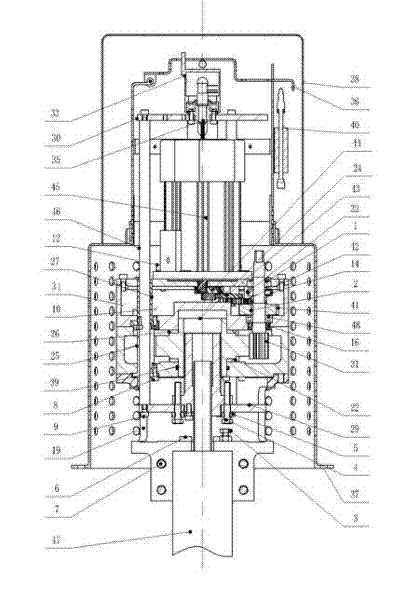

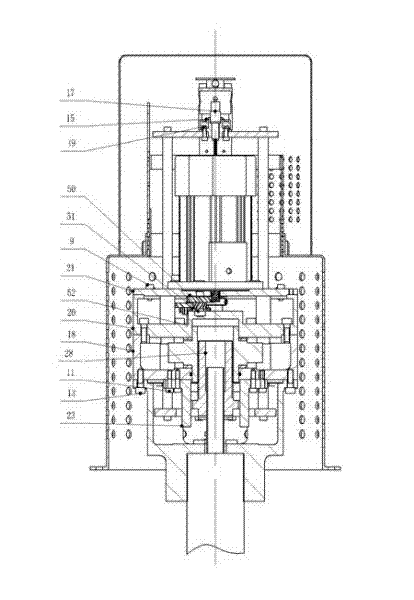

[0028] Referring to the accompanying drawings: A, install the oil-proof sleeve 27 on the upper box body 20, and press it with the hexagon socket head screw 8. Install the skeleton oil seal 16, the miniature bearing 48, and the four-axis 31;

[0029]B. Install a sealing ring 39 and a lower oil-proof sleeve 25 on the lower box body 18, press them with a hexagon socket head cap screw 8, install the lower pad 22, the large gear 24, and the upper pad 26. Install the content in A, press it with the inner hexagon screw 13, install the flat key 2, install the four-axis gear 41, install the bushing 32, press it with the set screw 14, install the single row deep groove ball bearing 1, install the miniature bearing 51, Install single row deep groove ball bearing 52, install three shafts 42, install two shafts 43, install one shaft 44, install miniature bearings 50, install balance weight 34, press with inner hexagonal screws 10, install cover 21, use inner hexagonal screws 9 Compress, in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com