Inversed rotating reductor

A rotary reducer, inverted technology, applied in mechanical equipment, transmission, transmission parts, etc., can solve the problems of brake failure, easy access to friction moving plate and friction stator, friction plate ablation, etc. Service life, reducing adverse effects, adjusting the effect of meshing clearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

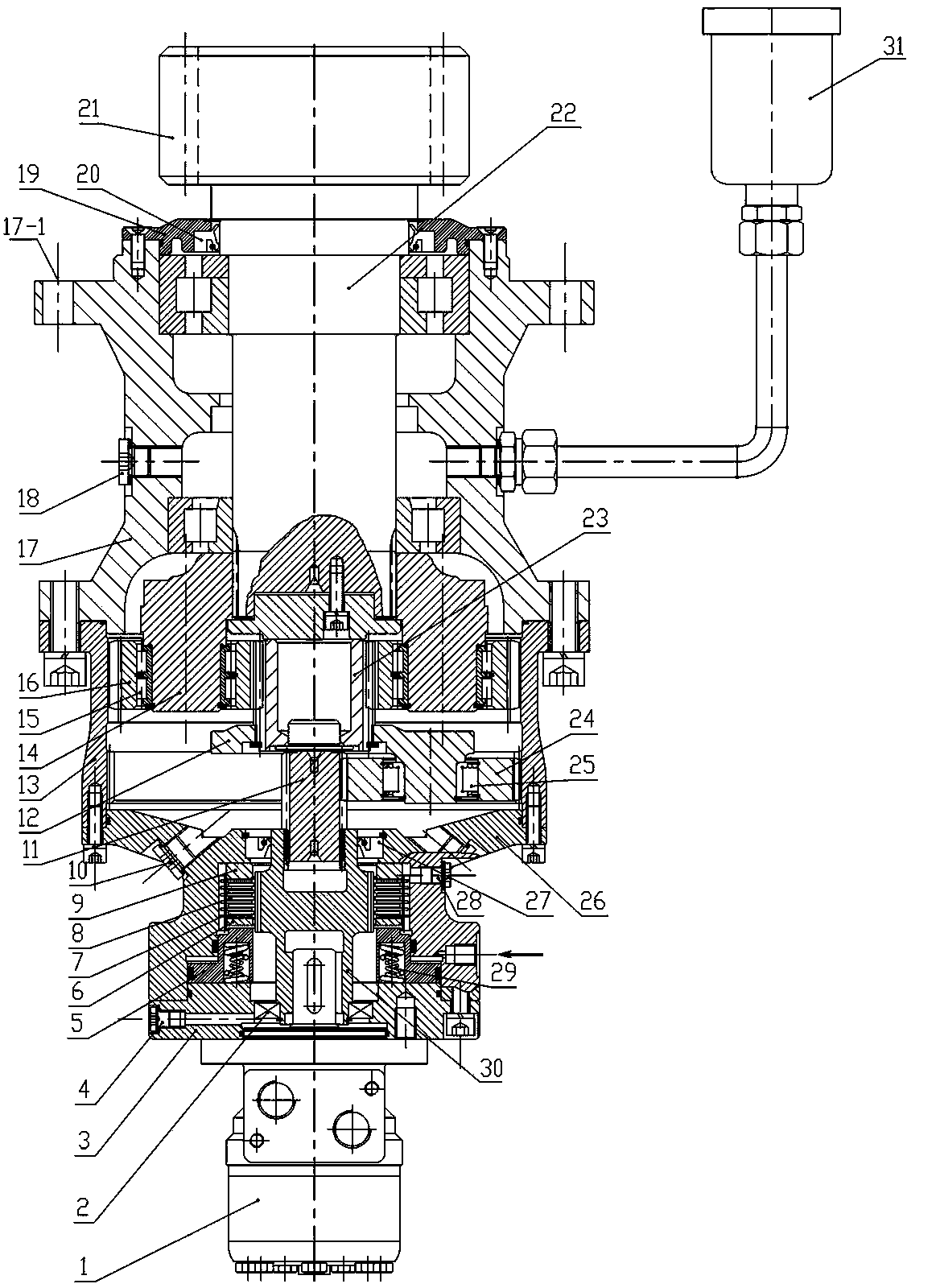

[0020] An inverted slewing speed reducer as shown in the accompanying drawings includes: a power source 1, a brake, a speed change mechanism and a power output mechanism. The power source 1 is installed at the lower end of the complete machine, the top of the power source 1 is connected to the brake, the top of the brake is connected to the speed change mechanism, and the top of the speed change mechanism is connected to the power output mechanism. The connecting flange 3, the brake housing 26, the transmission mechanism housing 13 and the bearing seat 17 are rigidly connected from bottom to top to form an integral casing.

[0021] The power source 1 is a hydraulic motor or an electric motor.

[0022] The brake is mainly composed of a connecting flange 3, a piston 5, an adjusting washer 6, a limit stop ring 9, a brake housing 26, a spring 29, a brake connecting shaft 30, a friction fixed plate 7 and a friction moving plate 8. The fixed plate has an external spline and is conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com