Hard EPR (ethylene propylene rubber) insulated instrument cable for ships and oceans and manufacturing method thereof

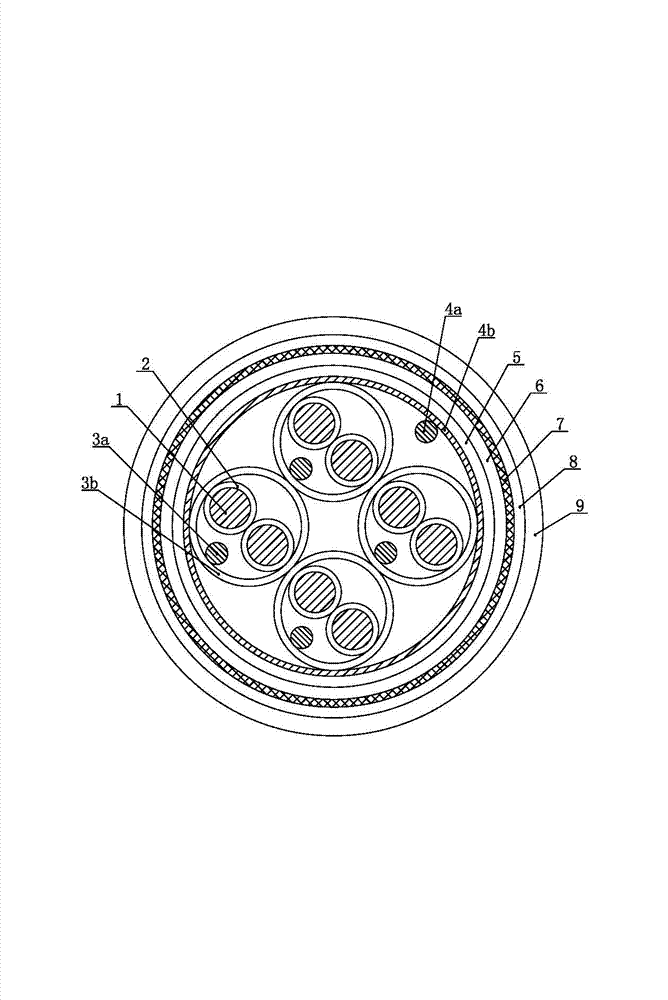

A technology of ethylene propylene rubber insulation and instrumentation cables, which is applied in the manufacture of insulated cables, rubber insulators, cables/conductors, etc., can solve the problem of increasing the effective load, poor mechanical properties, poor aging performance, poor shielding performance of aluminum foil polyester composite tapes, etc. problems, to achieve the effect of improving tensile performance, improving water repellency, and avoiding signal interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Prepare the raw materials of insulating materials according to the following components and weight content: ethylene-propylene rubber 2470: 11 parts; ethylene-propylene rubber 4044: 9 parts; high-pressure polyethylene (melt index: 2.0): 1.0 parts; dicumyl peroxide DCP: 0.5 parts; triallyl isocyanurate TAIC-70: 0.3 parts; 2-mercaptobenzimidazole MB: 0.5 parts; titanium dioxide: 1 part; paraffin oil: 1.0 parts; zinc oxide: 1.0 parts ; Microcrystalline paraffin: 0.6 parts; Stearic acid: 0.2 parts; White carbon black: 1 part; Ultrafine talcum powder: 10 parts; Modified calcined clay: 12 parts;

[0022] The production includes the following steps in sequence: First, mix ethylene-propylene rubber 2470, ethylene-propylene rubber 4044 and high-pressure polyethylene; then add titanium dioxide, paraffin oil, zinc oxide, microcrystalline paraffin, stearic acid, and white carbon black in sequence , ultra-fine talcum powder and modified calcined clay for 9 minutes to make each compo...

Embodiment 2

[0025] Prepare the raw materials of insulating materials according to the following components and weight content: ethylene-propylene rubber 2470: 11 parts; ethylene-propylene rubber 4044: 9 parts; high-pressure polyethylene (melt index: 2.0): 1.2 parts; dicumyl peroxide DCP: 0.8 parts; triallyl isocyanurate TAIC-70: 0.35 parts; 2-mercaptobenzimidazole MB: 0.6 parts; titanium dioxide: 1.3 parts; paraffin oil: 1.2 parts; zinc oxide: 1.3 parts ; Microcrystalline paraffin: 0.8 parts; Stearic acid: 0.4 parts; White carbon black: 1.5 parts; Ultrafine talcum powder: 12 parts; Modified calcined clay: 14 parts;

[0026] The production includes the following steps in sequence: First, mix ethylene-propylene rubber 2470, ethylene-propylene rubber 4044 and high-pressure polyethylene; then add titanium dioxide, paraffin oil, zinc oxide, microcrystalline paraffin, stearic acid, and white carbon black in sequence , ultra-fine talc powder and modified calcined clay for 10 minutes to make each...

Embodiment 3

[0029] Prepare the raw materials of insulating materials according to the following components and weight content: ethylene-propylene rubber 2470: 11 parts; ethylene-propylene rubber 4044: 9 parts; high-pressure polyethylene (melt index: 2.0): 1.5 parts; dicumyl peroxide DCP: 1.0 parts; triallyl isocyanurate TAIC-70: 0.4 parts; 2-mercaptobenzimidazole MB: 0.8 parts; titanium dioxide: 1.5 parts; paraffin oil: 1.5 parts; zinc oxide: 1.5 parts ; Microcrystalline paraffin: 1.0 parts; Stearic acid: 0.5 parts; White carbon black: 2 parts; Ultrafine talcum powder: 15 parts; Modified calcined clay: 16 parts;

[0030] The production includes the following steps in sequence: First, mix ethylene-propylene rubber 2470, ethylene-propylene rubber 4044 and high-pressure polyethylene; then add titanium dioxide, paraffin oil, zinc oxide, microcrystalline paraffin, stearic acid, and white carbon black in sequence , superfine talcum powder and modified calcined clay for 12 minutes to make each c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com