Method for manufacturing contact plug

A manufacturing method and technology of contact plugs, which are applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve the problems affecting the response speed of devices and the increase of contact plug resistance, so as to improve the response speed and reduce the contact plug resistance , The effect of high etching precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

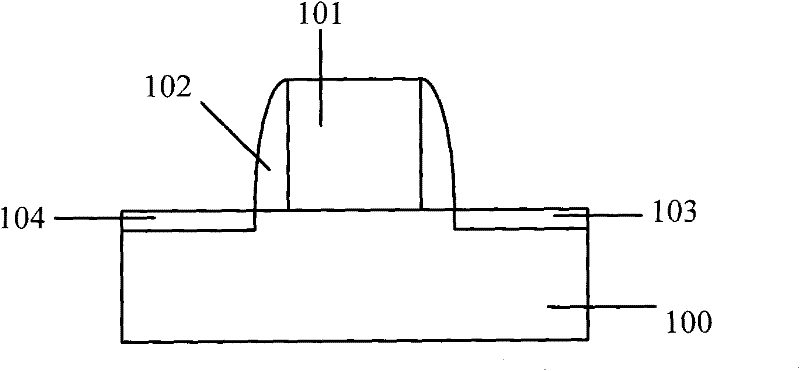

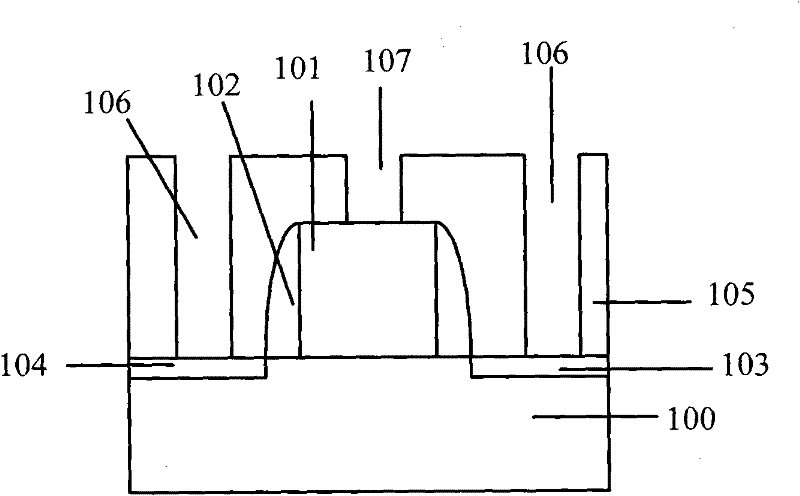

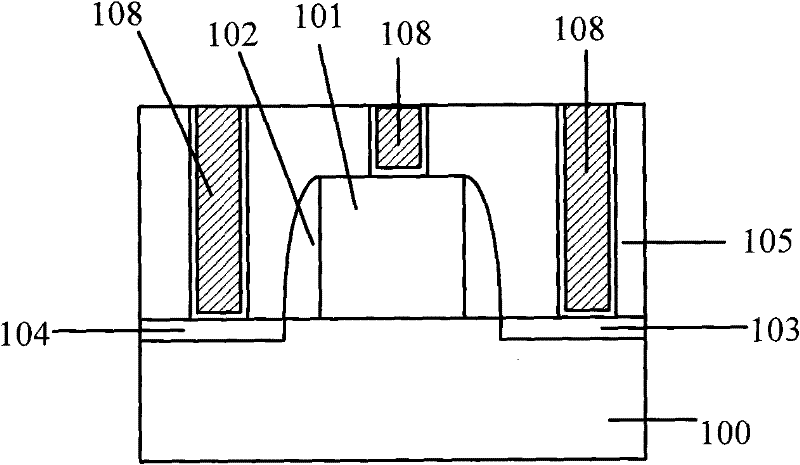

[0039] In the present invention, a first contact hole is formed in the first interlayer dielectric layer on the source electrode and the drain electrode, a second contact hole is formed on the first contact hole, the first metal layer and the first metal layer filled in the first contact hole The second metal layer constitutes a contact plug, which improves the etching precision of etching the first contact hole and the second contact hole, and the resistivity of the second metal layer filled in the second contact hole is smaller than that of the first metal layer , reducing the contact plug resistance of the source and drain of the device.

[0040] Specifically, the present invention provides a method for manufacturing a contact plug. Please refer to Figure 4 , is a schematic flow chart of the method for making the contact plug of the present invention. The methods include:

[0041] In step S1, a semiconductor substrate is provided, and a gate structure and a first interl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com