Electrodynamic linear oscillating motor

A technology for driving motors and motors, which can be used in electrical components, electromechanical devices, etc., and can solve problems such as inappropriateness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

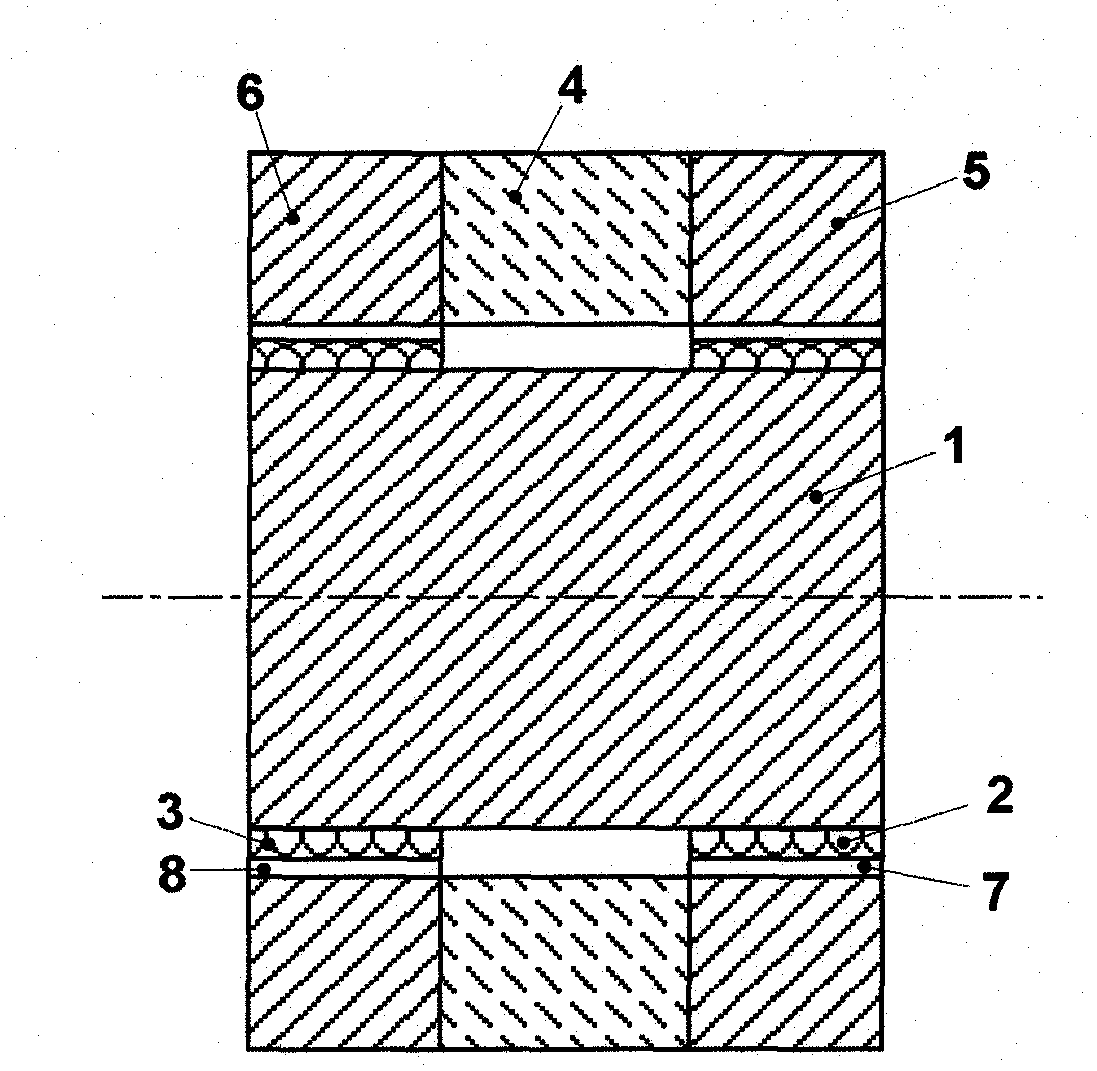

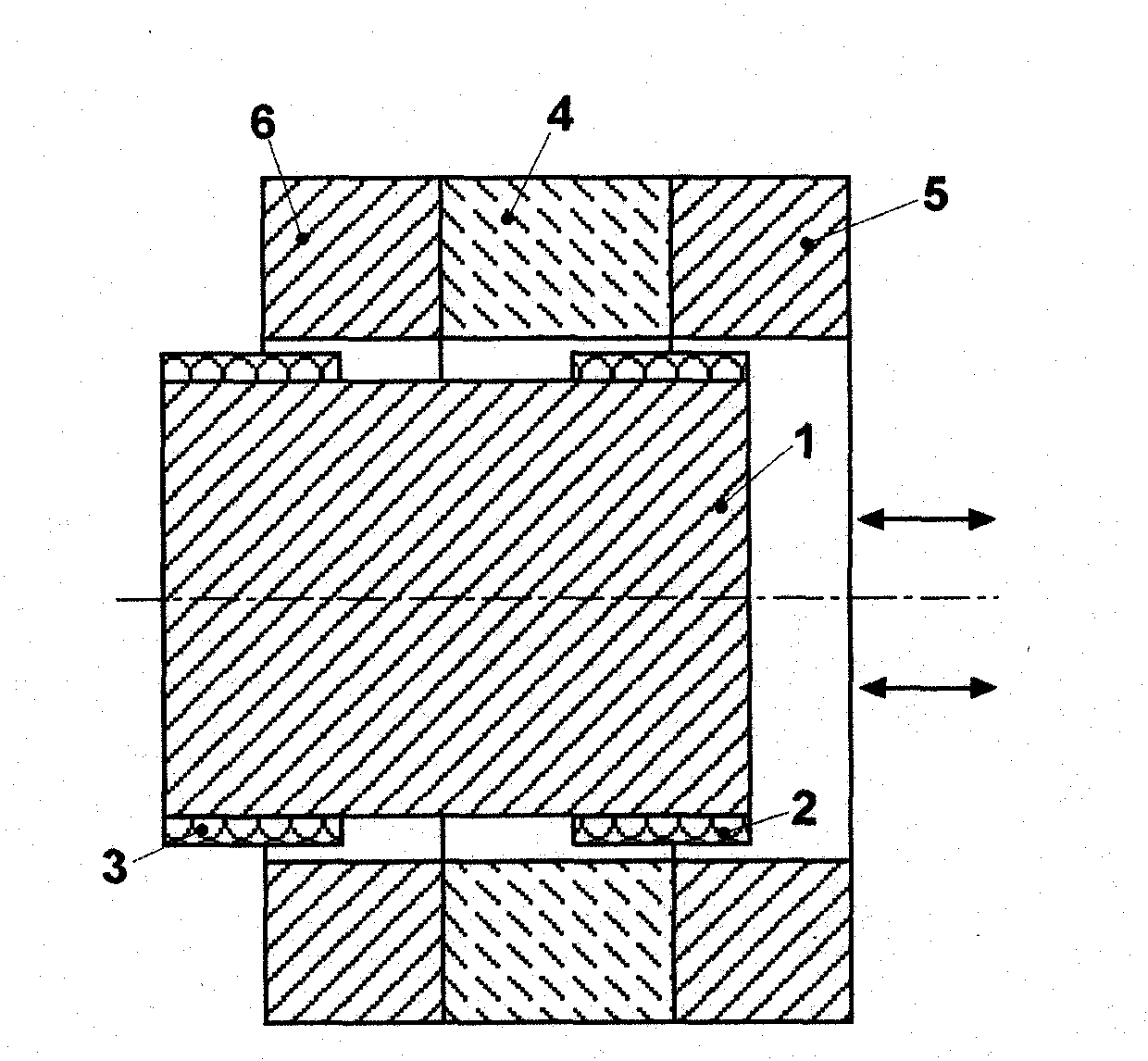

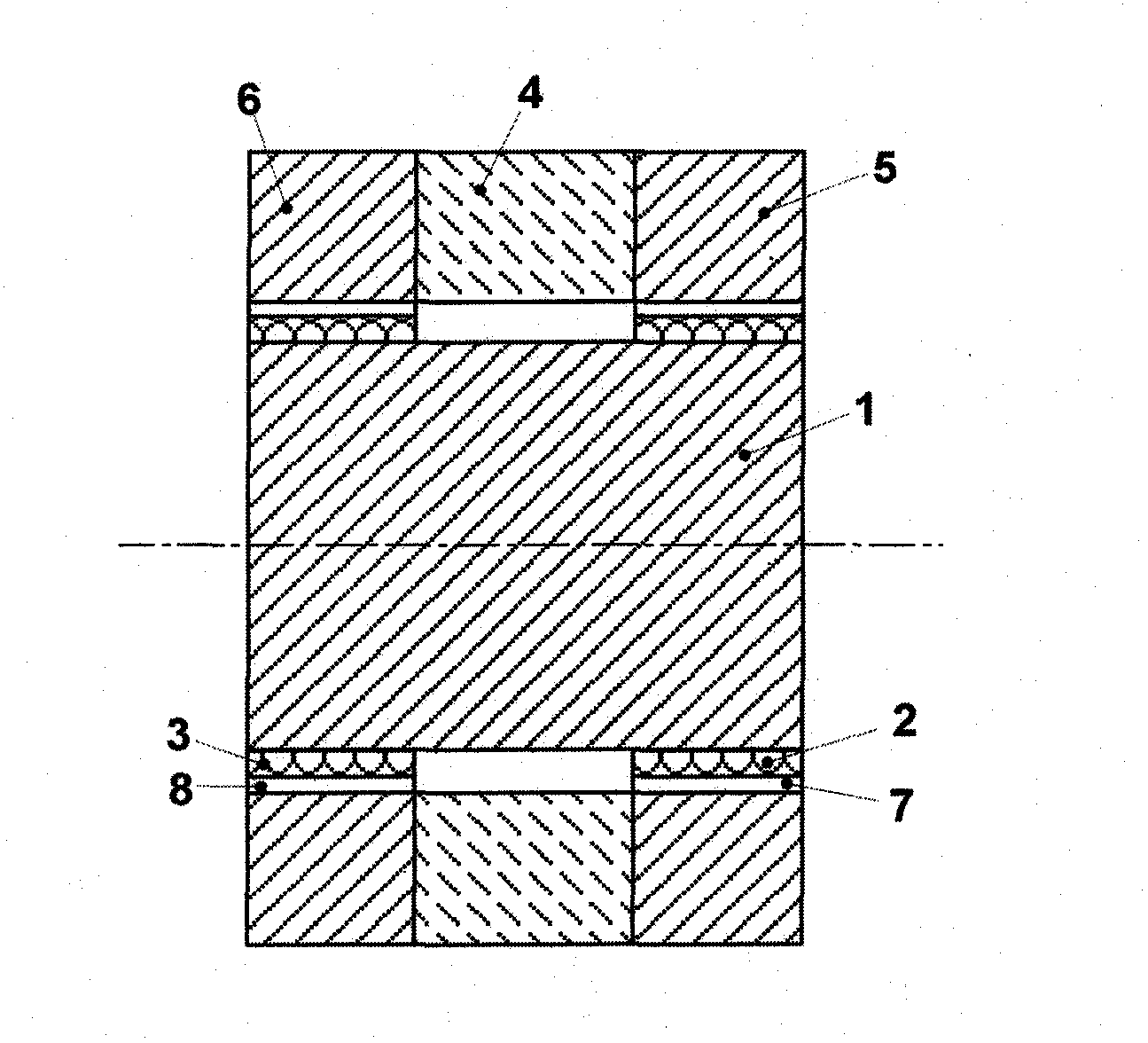

[0028] Such as figure 1 As shown, the stator system of the linear oscillating motor is composed of an annular disk-shaped permanent magnet 4 magnetized in the axial direction, and ring-shaped first pole pieces 5 and second pole pieces 6 are respectively provided on both ends thereof. The inner and outer diameters of the pole pieces 5 and 6 are equal to the inner and outer diameters of the magnet 4 .

[0029] The oscillating system is concentrically arranged and installed inside the stator system in a manner that can move along the axial direction. The oscillating system is composed of a ferrite core 1, on which a first excitation coil 2 and a second excitation coil 2 are wound. Energize coil 3. As long as the oscillating system is in its central position, the first coil 2 is located in the center of the first magnetic gap 7 and the second coil 3 is correspondingly located in the center of the second magnetic gap 8 . The movable supply wires for the coils 2, 3 need only be sl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com