Piezoelectric fan, radiator and electronic equipment

A piezoelectric fan and fan technology, which is applied in the construction of electrical equipment components, mechanical equipment, cooling/ventilation/heating transformation, etc., can solve the problems of unstable output airflow and low service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

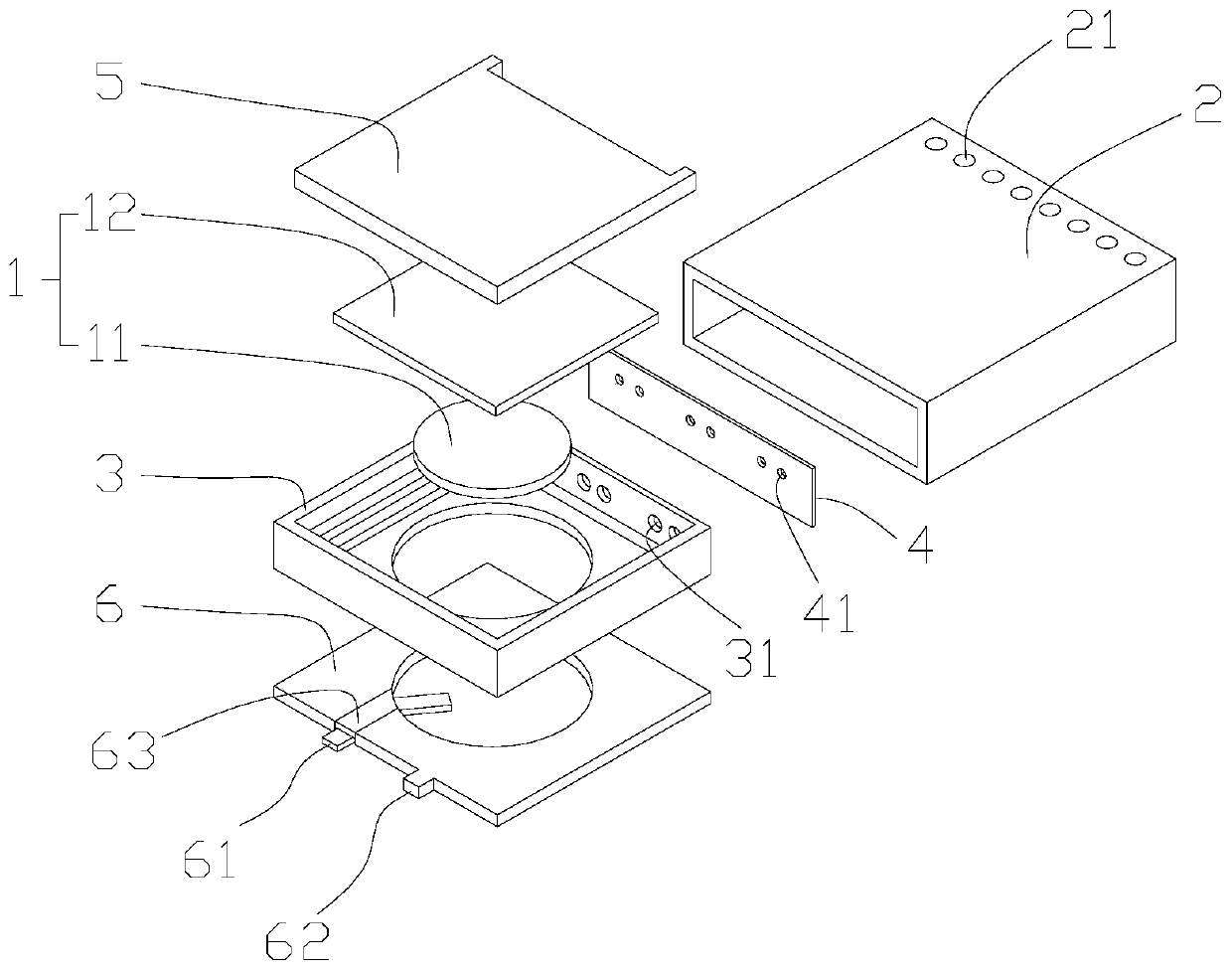

[0045] Such as Figure 1-9 As shown, this embodiment proposes a piezoelectric fan, which includes a fan body and a piezoelectric element 1. The piezoelectric element 1 is arranged inside the fan body. The piezoelectric element 1 deforms and squeezes fluid to be discharged from the fan body to achieve air flow. role.

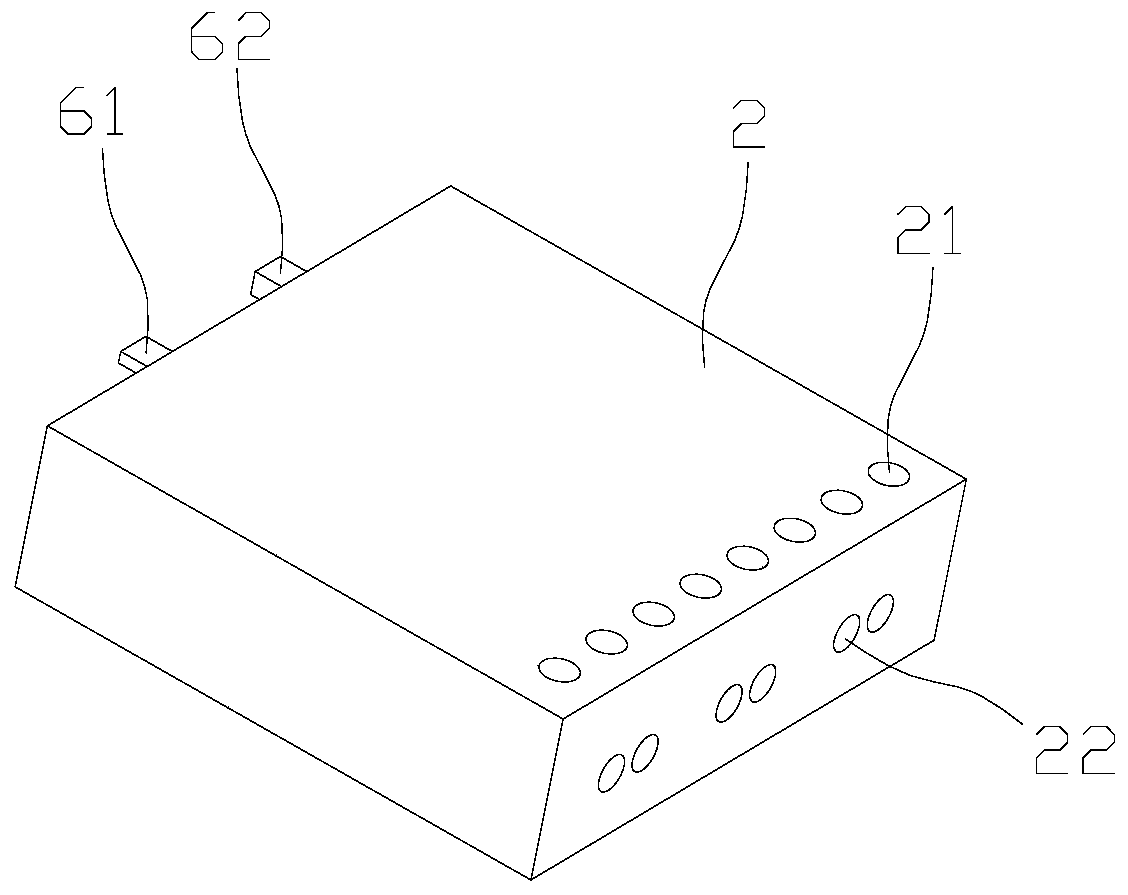

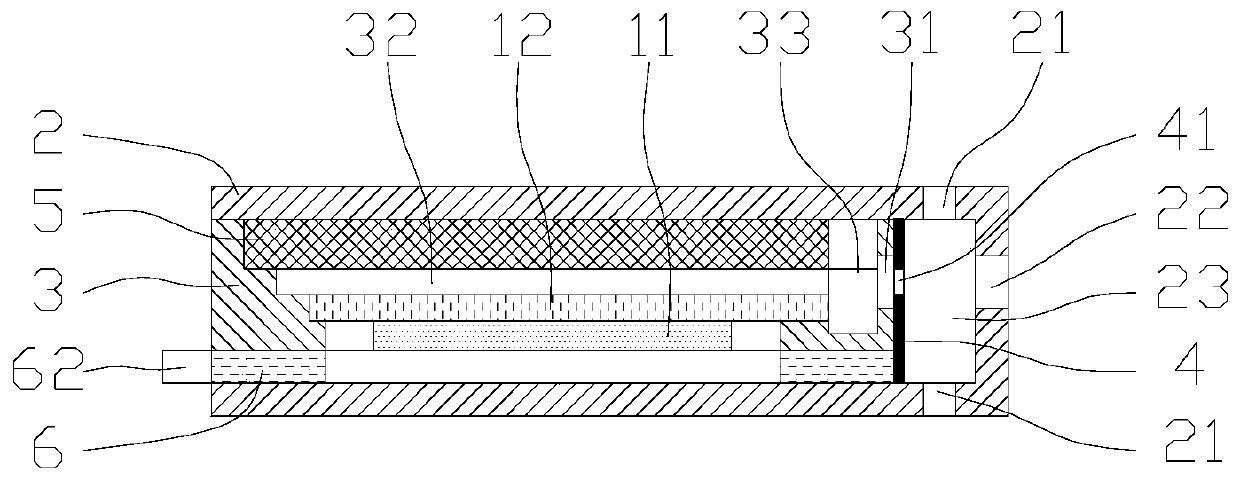

[0046] The fan body includes a casing 2 and a support 3 , the casing 2 is open at one end, and the support 3 can be inserted into the casing 2 from the opening of the casing 2 . The casing 2 is provided with an inlet 21 and an outlet 22 , and both the inlet 21 and the outlet 22 are arranged at an end of the casing 2 away from the opening. Specifically, the support member 3 is inserted into the housing 2, there is a gap between the outer end surface of the inner end of the support member 3 inserted into the housing 2 and the inner wall of the housing 2, and the inner end of the support member 3 and the inner wall of the housing 2 A jet cavity 23 is formed, the i...

Embodiment 2

[0075] Such as Figure 10 As shown, this embodiment is basically the same as Embodiment 1, the only difference is that there are two piezoelectric elements 1 and two electrode plates 6 in this embodiment, and no separator is required. Specifically, the two piezoelectric elements 1 are arranged symmetrically inside the support member 3 , the substrates 12 of the two piezoelectric elements 1 are arranged close to and spaced apart from each other, and a generating cavity 32 is formed between the two substrates 12 . The upper and lower ends of the supporting member 3 are provided with electrode plates 6, and the two electrode plates 6 are connected to the current for the two piezoelectric elements 1 respectively, and a buffer is formed between the ends of the two piezoelectric elements 1 and the inner wall of the supporting member 3 Cavity 33.

[0076] When the two piezoelectric elements 1 act on the generating chamber at the same time, the pumping force is enhanced, and the flow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com