Double-member alternating-working piezoelectric fan insulation structure and electric fan thereof

A technology of alternating work and insulating structure, applied in the field of piezoelectric fans, it can solve the problems of difficult to guarantee single-layer insulation, high driver voltage, easy insulation drop, etc., and achieve the effects of strong elasticity, good sealing performance and easy operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further clarified below in conjunction with specific drawings. This specific embodiment is implemented on the premise of the technical solution of the present invention. It should be understood that these modes are only used to illustrate the present invention and are not intended to limit the scope of the present invention.

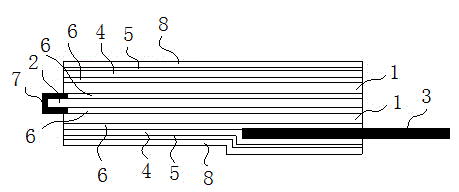

[0018] The two-body alternately working piezoelectric fan includes two parts: a piezoelectric fan chip and a three-layer structure insulating layer. The piezoelectric fan chip is the core part of the heat dissipation function of the heating device, and the piezoelectric fan realizes the function through the chip. The three-layer structure insulation layer is to ensure that the piezoelectric fan can work normally in harsh environments for a long time. If left unprotected, the piezo fan rapidly degrades in the air, eventually leading to failure. Therefore, it is very important to do a good job of insulating the piezoel...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Insulation properties | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com