Piezoelectric fan with L-shaped framework laminating type blades

A piezoelectric fan and blade technology, which is applied to piezoelectric effect/electrostrictive or magnetostrictive motors, electrical components, non-variable pumps, etc., can solve the problem of amplitude drop and piezoelectric fans can not reach the best Performance, it is difficult to give full play to the energy density of piezoelectric ceramic sheets, etc., to achieve the effect of increasing the amplitude and fundamental frequency, improving the efficiency of air outlet and heat dissipation, and increasing the working area and sweeping area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

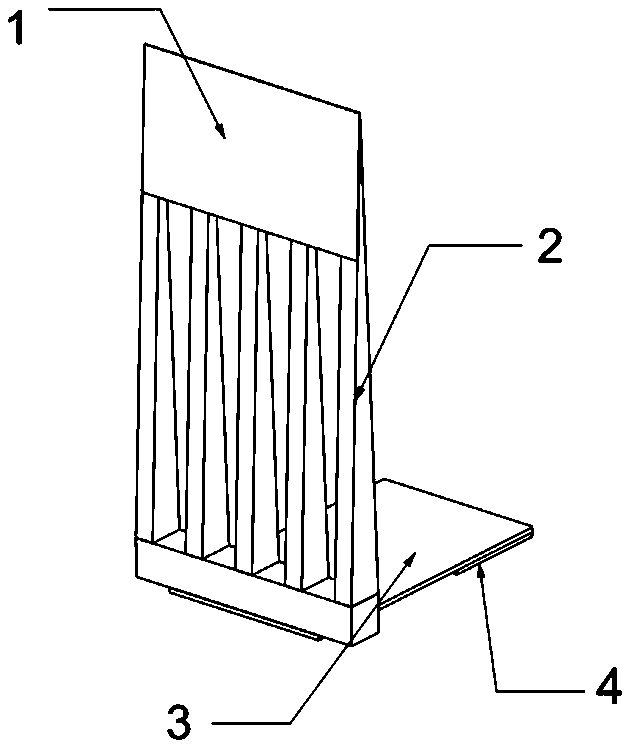

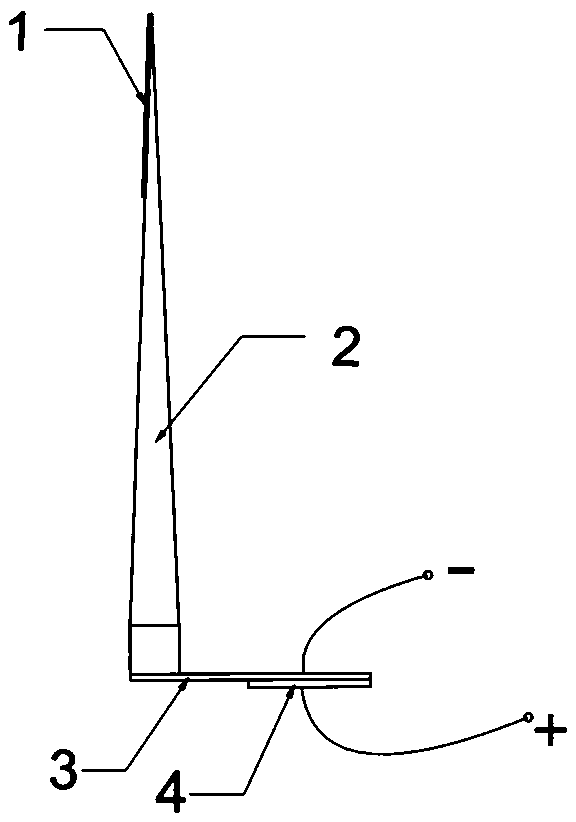

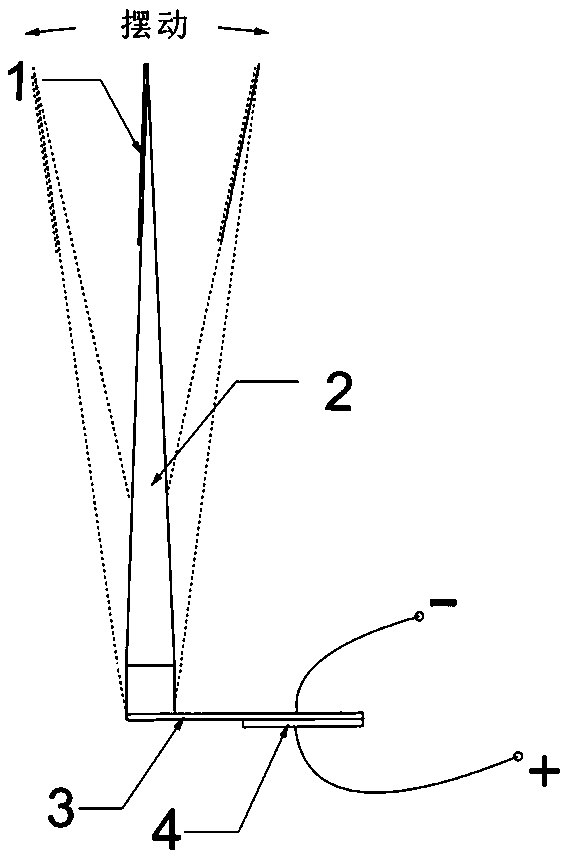

[0027] see figure 1 A piezoelectric fan with film-covered blades includes an elastic metal sheet 3 and a piezoelectric ceramic 4, and the piezoelectric ceramic 4 is bonded and fixed to one side edge of the elastic metal sheet 3 by epoxy resin.

[0028] The other side edge of the other side of the elastic metal sheet 3 is fixedly equipped with an upright bracket 2 . The material of the support 2 is PMMA organic material; the support 2 is grid-shaped, the bottom of the grid is fixedly connected to the cross bar, and the cross bar is fixedly connected to the elastic metal sheet 3; the vertical section of the grid bar is a triangle with a large lower end and a small upper end.

[0029] A film 1 is installed on one third of the upper part of one side of the support 2, and the material of the film 1 is polytetrafluoroethylene.

[0030] The elastic metal sheet 3 and the upright support 2 form an L-shaped skeleton.

[0031] see figure 2 , the two sides of the elastic metal sheet ...

Embodiment 2

[0046] When the material of the bracket 2 is steel, the size and structure of the bracket 2 are the same as those in the embodiment 1; the material of the film 1 is still polytetrafluoroethylene. The size of the piezoelectric ceramic sheet 4 and the elastic metal sheet 3 used for driving, energy transmission, and displacement amplification will increase correspondingly, and they are respectively set to 30×40 mm and 40×60 mm.

[0047] In this embodiment, since the basic structure is still an L-shaped skeleton film-covered blade structure, the fundamental frequency and amplitude coupling limitations of the piezoelectric fan will also be optimized, and the performance will be improved.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com