Robot-assisted numerical control full-automatic production line

A technology of robots and CNC lathes, applied in the direction of automatic entry/exit of workpieces, metal processing mechanical parts, metal processing, etc., can solve problems such as waste of human resources, loud noise and highly repetitive movements in CNC machining, physical injuries to workers, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

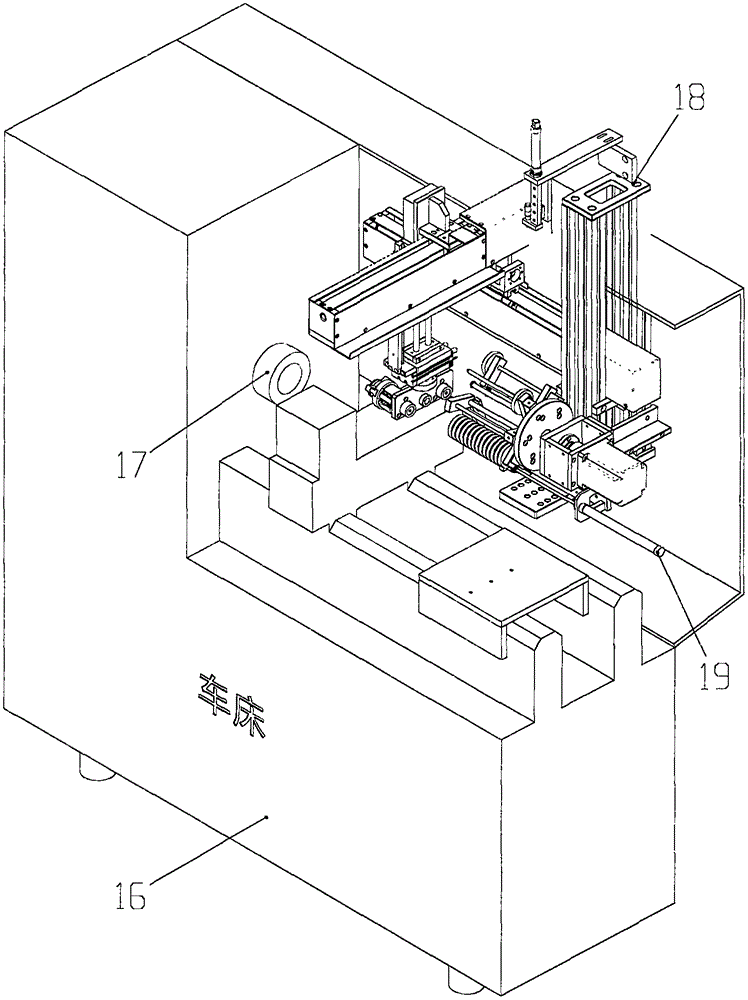

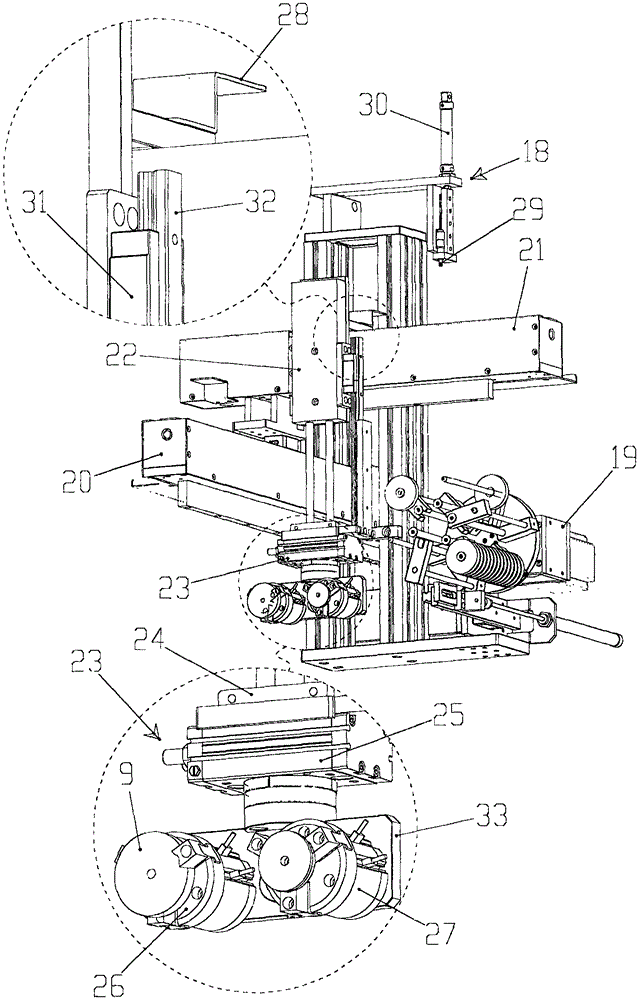

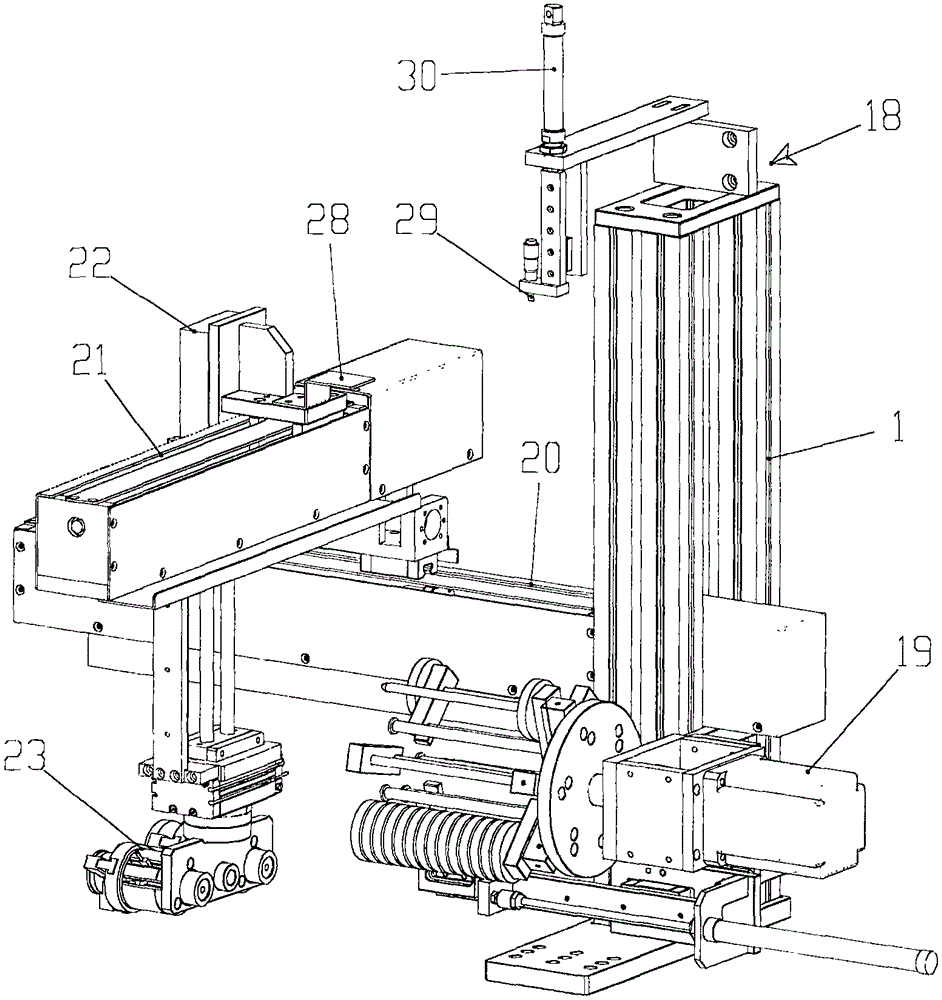

[0042] Embodiments of the present invention will now be described with reference to the drawings, in which like reference numerals represent like elements. As mentioned above, the present invention provides a robot-assisted CNC fully automatic production line, which is used to realize fully automatic unmanned CNC turning operations. The robot grabs unturned workpieces from the silo system to the CNC lathe to realize CNC turning, and then Place the turned workpieces into the bin system.

[0043] figure 1 It is a structural schematic diagram of a robot-assisted numerically controlled full-automatic production line of the present invention, figure 2 , 3 , 4 is the structural representation of the robot of the robot-assisted numerical control full-automatic production line of the present invention, Figure 5 , 6 It is a structural schematic diagram of the silo system of the robot-assisted numerically controlled full-automatic production line of the present invention, Figure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com