Breathable waterproof soles and shoes

A breathable waterproof and breathable hole technology is applied in the field of shoe soles and shoes, which can solve the problems of complex manufacturing process, high cost, and inability to install buffer devices, and achieve the effects of simplified processing technology, improved waterproof performance and low manufacturing cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

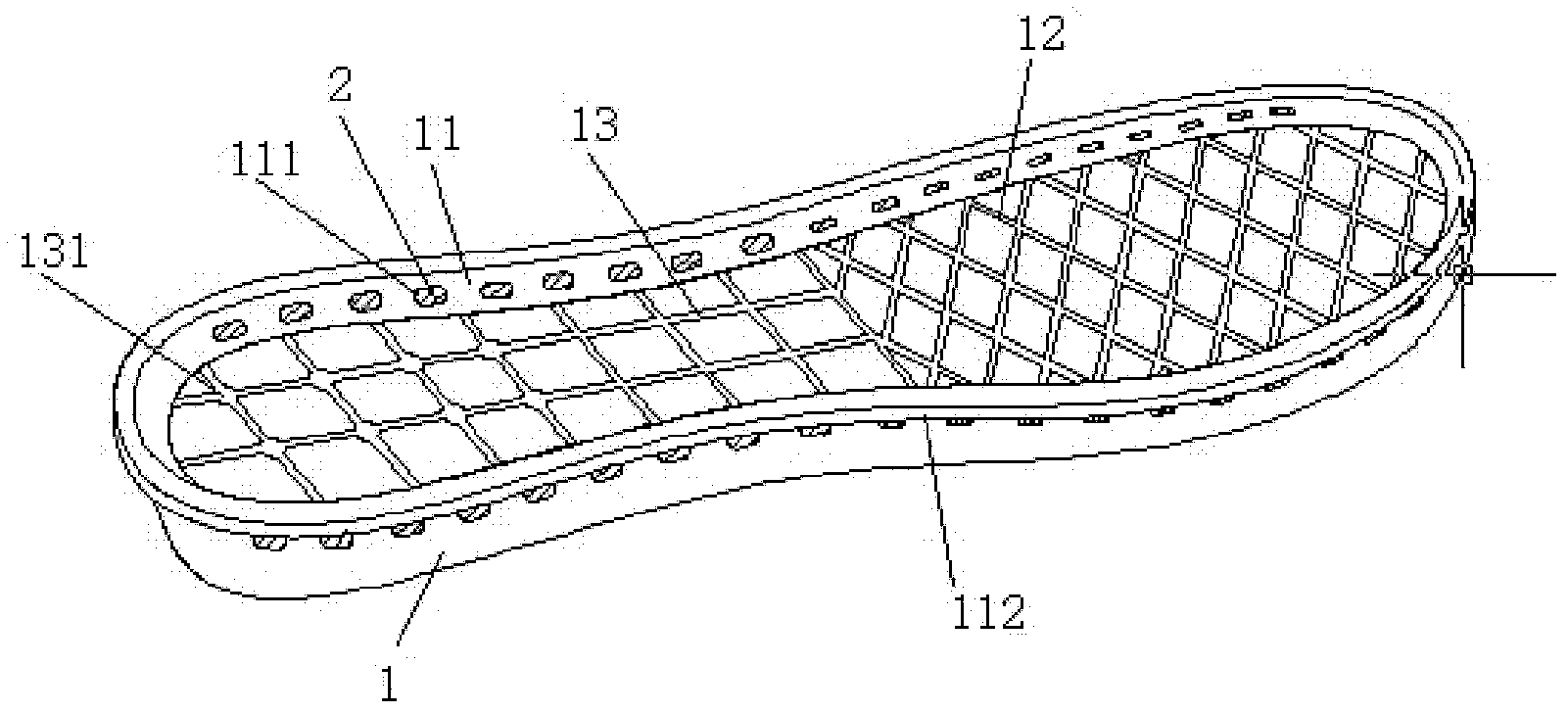

[0037] Such as Figure 1 to Figure 3 As shown, a breathable and waterproof shoe sole includes a tread 1 made of rubber, an upwardly protruding flange 11 is provided on the periphery of the tread 1, and the flanges 11 on the left and right sides of the tread 1 are substantially horizontally arranged There are air holes 111, the air holes 111 run through the inner and outer sides of the flange 11, one or two layers of waterproof air-permeable cloth 2 are pressed in the body of the flange 11, and are injection molded together with the bottom 1, which is more beautiful and tightly sealed. Waterproof air-permeable cloth 2 is suitable for the facade shape of flange 11, and waterproof air-permeable cloth 2 seals the water around air hole 111 and air hole 111, but gas can pass through waterproof air-permeable cloth 2, so that water cannot pass through the horizontal air hole. 111, but the fresh air from the outside and the moisture in the shoes can enter and exit from the waterproof b...

Embodiment 2

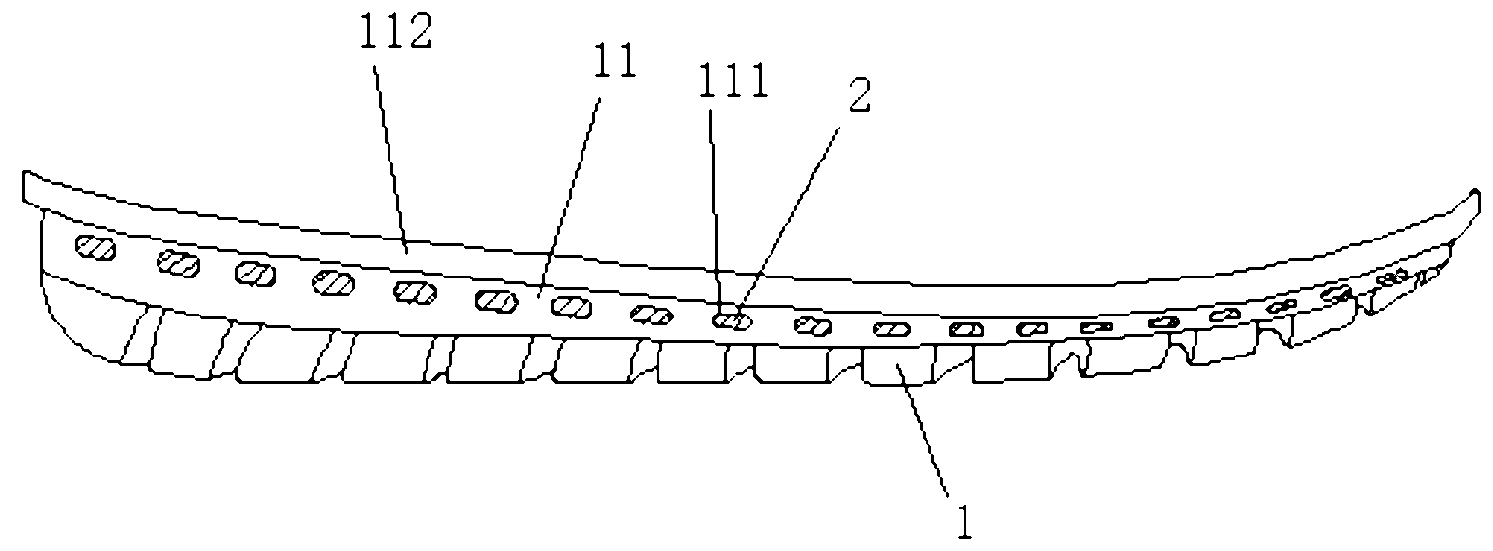

[0042] Such as Figure 4 and Figure 5 As shown, a breathable and waterproof shoe sole includes a tread 1 made of rubber, an upwardly protruding flange 11 is provided on the periphery of the tread 1, and the flanges 11 on the left and right sides of the tread 1 are substantially horizontally arranged Air vent 111 is arranged, and air vent 111 runs through the inner and outer sides of flange 11. Considering that the waist part of the sole 1 often needs to be bent and twisted, in order to ensure the service life of the sole, the vent 111 is only located at the bottom of the sole 1. The heel portion and the front palm portion, the air vent 111 connects the inner and outer sides of the heel portion and the front palm portion when stepping on the bottom. Because there is a large compartment in the bottom 1, the air circulation is faster, and it is enough to take a breath through the air holes 111 of the heel and the front palm, so as to avoid the opening of the shoe waist along th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com