Accurate weighing type packaging machine system and filling method

A weight-based, packaging machine technology, applied in the direction of packaging, transportation and packaging, packaging item types, etc., can solve problems such as errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

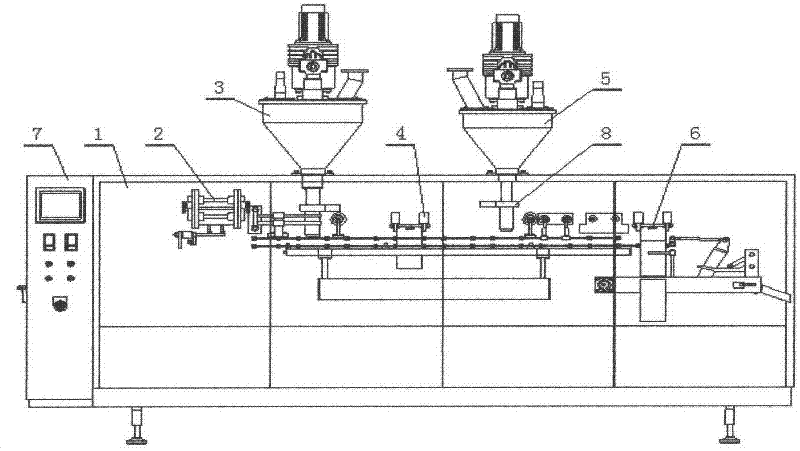

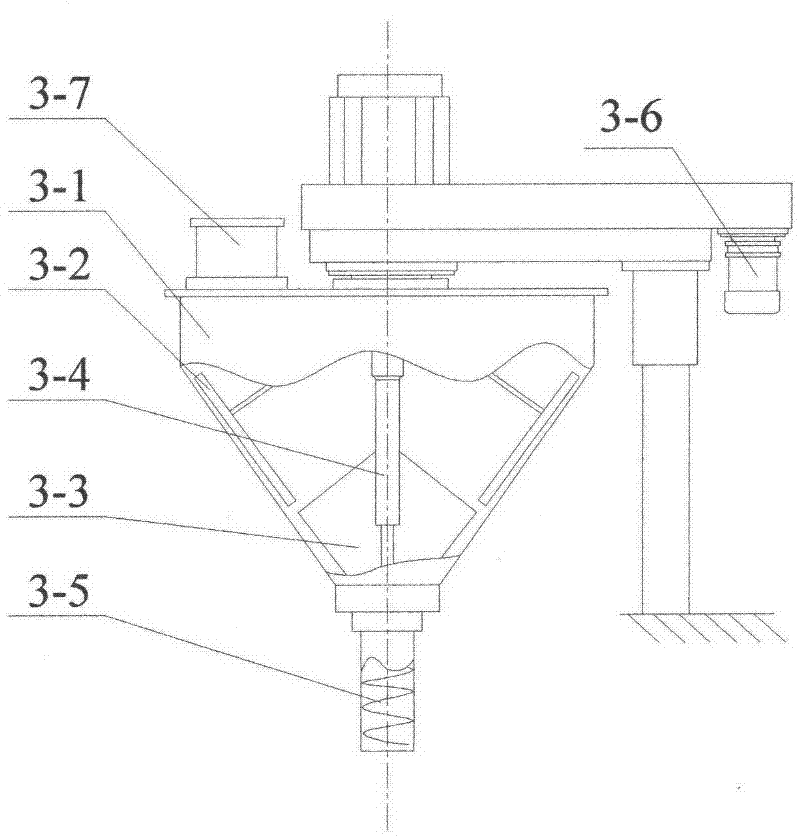

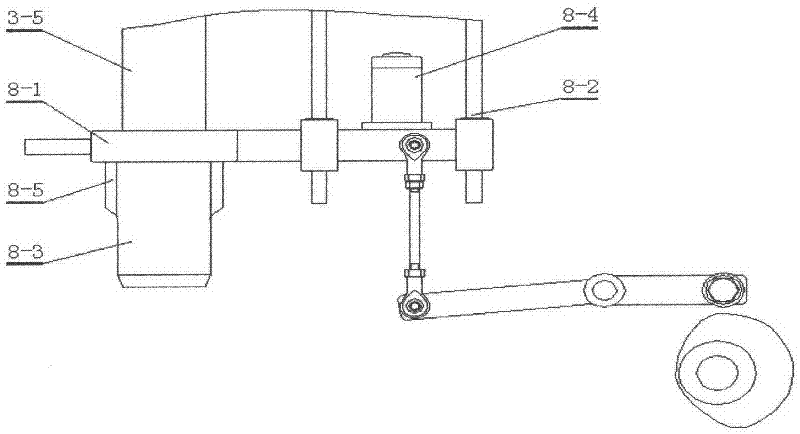

[0018] Accurate weighing packaging machine system, the system includes a material filling machine, a weighing and monitoring mechanism for the filled packaging bag, a servo mechanism 2 for packaging bag conveying and designated station docking, a sub-packaging post-processing mechanism 6, and supporting The key to the positioning and connecting devices of the management unit 7 and each mechanism is that at least two subpackaging stations of the material filling machine are set in the system, and a supporting subpackaging station is added to each subpackaging station of the material filling machine. Quantity monitoring device 4, the material filling machine corresponding to the sub-packing station is arranged in descending order of the weight order or volume order of the sub-package material, and the refilling in the material filling machine at the next station is the design analysis. The error correction of the loading is carried out until the weight accuracy of the material in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com