Sectional filling method of old lane

A technology for old lanes and roadways, which is applied to filling materials, earth cube drilling, mining equipment, etc., which can solve the problems of normal propulsion, high filling cost, and long time consumption, so as to avoid waste of filling material, low filling cost and high filling efficiency high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

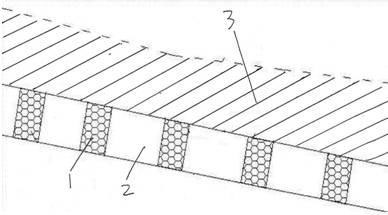

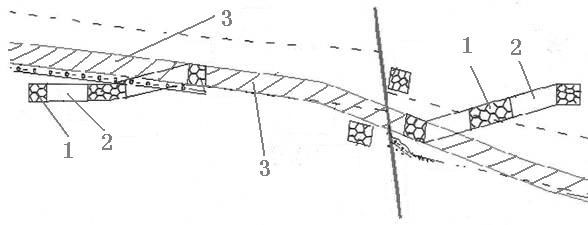

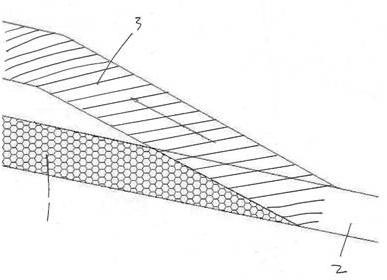

Image

Examples

Embodiment Construction

[0017] The section filling method for old lanes of the present invention includes the following steps:

[0018] A. According to the actual situation of the working face, draw the layout diagram of the old lanes of the working face in advance, and mark the positions of the old lanes, working faces and other roadways, old lane support methods and other parameters in detail, so as to prepare for the next filling construction. ready;

[0019] B. According to the actual conditions of the working face and the existing technology, generally choose fly ash or slag ash and other materials with low sulfur content and non-radioactive materials to fill. In order to ensure that the size of the filling material will not be too large to affect the filling effect, the filling After the materials are screened, they are bagged and go down the well;

[0020] C. According to the layout of old lanes, roof conditions, and working face advancing speed, fill the old lanes at least 50m ahead of the working ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com