Mechanical clock mechanism and design method thereof

A technology of mechanical clocks, design methods, applied in mechanically driven clocks, movement size, clocks, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

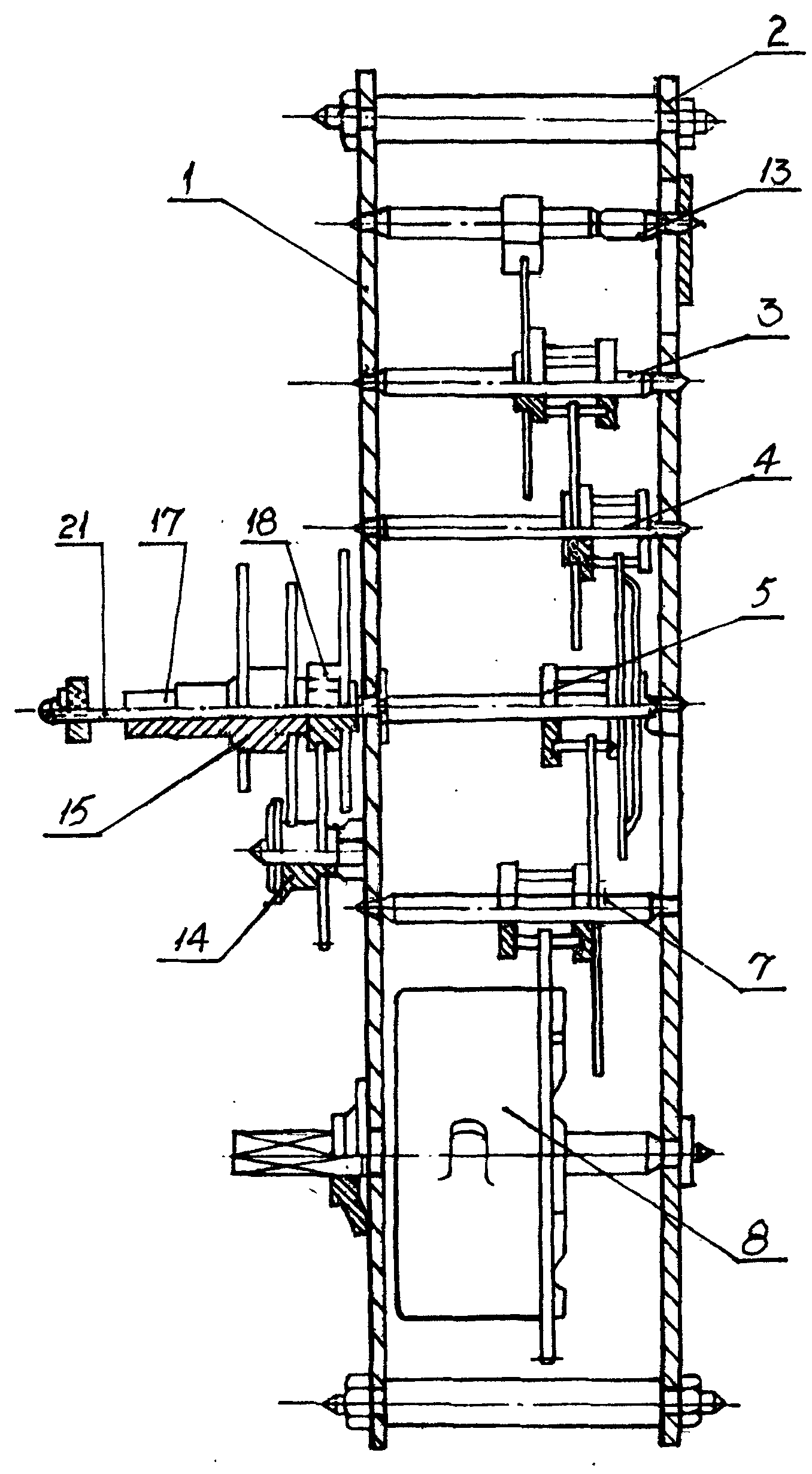

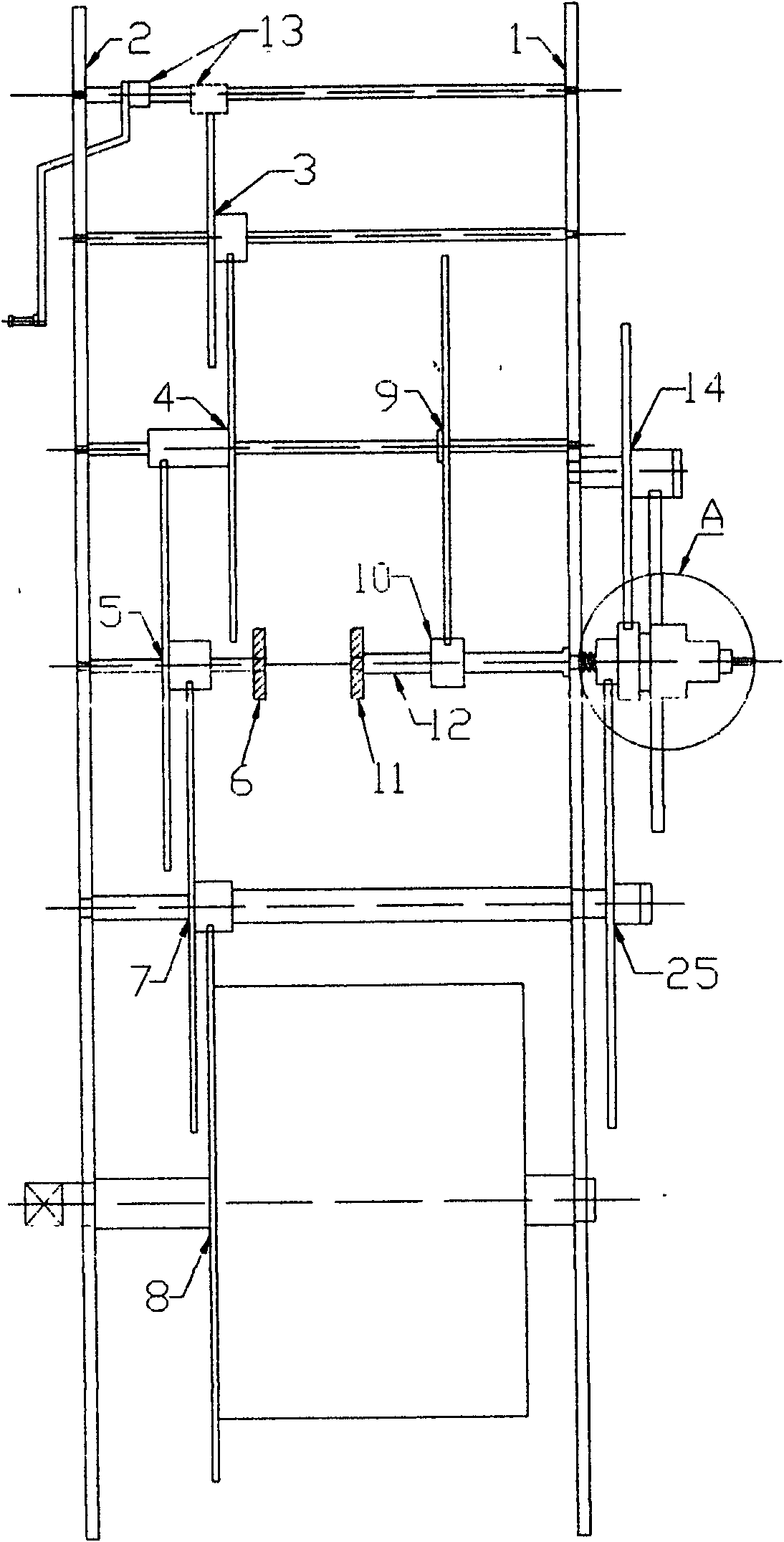

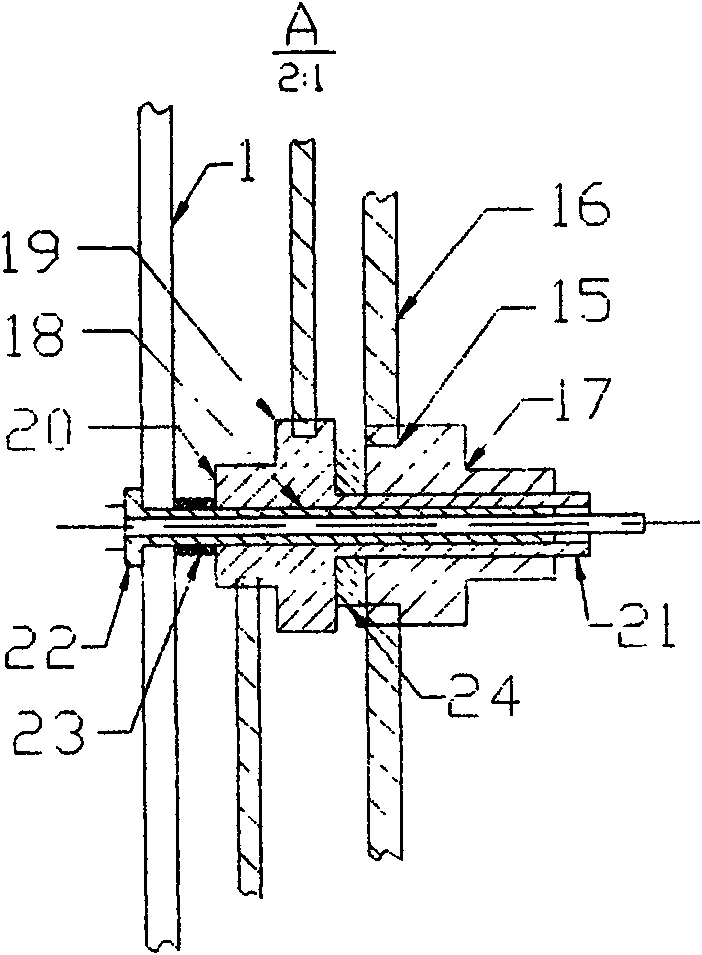

[0033] A design method for a mechanical clock movement according to Embodiment 1 of the present invention, which includes an ordinary three-needle mechanical clock used by ordinary consumers as the design object, and is adopted to meet the national standard GB / T 22772- "Mechanical Pendulum Clock" The technical index of 2008 is the premise, and the mechanical power mechanism of the clock movement is based on the spring-type power source. The mechanical desk clock and mechanical wall clock with a winding cycle of 31 days provide an improved design of the hour, minute, and second three-hand coaxial The overall design scheme of the mechanical clock movement with heart structure. On this basis, taking the existing mechanical clock movement as the prior art, its structure is: the front splint, the rear splint and the splint column between the two splints together constitute the support frame of the mechanical clock movement described in Embodiment 1 , the head wheel assembly include...

Embodiment 2

[0038] The design method of a mechanical clock movement described in Embodiment 2 of the present invention includes the design requirements of seat-type high-end three-needle mechanical clocks used by high-end consumers, so as to meet the national standard "Mechanical Pendulum Clock" GB / The technical index of T 22772-2008 is the premise, and the clockwork power source is used as the mechanical power mechanism of the clock movement. The mechanical seat type high-end see-through clock with a winding cycle of 31 days provides hours, minutes and seconds with improved design. The overall design scheme of a mechanical clock movement with a three-needle concentric structure. On this basis, taking the existing mechanical clock movement as the prior art, its structure is: the front splint, the rear splint and the splint column between the two splints together constitute the support frame of the mechanical clock movement described in Embodiment 2 The head wheel assembly includes a whee...

Embodiment 3

[0043] A design method of a mechanical clock movement in Embodiment 3 of the present invention, which includes meeting the design requirements of high-end three-needle mechanical clocks used by high-end consumers, so as to meet the national standard GB / T 22772-2008 of "Mechanical Pendulum Clock" The technical index is the premise, and the power source of the uniform wheel is used as the mechanical power mechanism of the clock movement. The mechanical stand-type high-end see-through clock with a winding cycle of 14 days provides the improved design of the hour, minute and second three needles at the same time. The overall design scheme of the mechanical clock movement with the axis structure. On this basis, with existing mechanical clock movement (see figure 1 ) is the prior art, its structure is: the splint column between the front splint, the rear splint and the two splints together constitute the support frame of the mechanical clock movement described in the present embodim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com