Method and system for processing columnar lithium battery

A processing method and processing system technology, applied in sustainable manufacturing/processing, non-aqueous electrolyte battery, electrolyte battery manufacturing and other directions, can solve the problems of increasing waste of raw materials and other resources, inconsistent processing procedures, and low quality of finished products, etc. The effect of production cost and production cycle, strong process continuity and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] In this embodiment, the mainstream power supply adopts single-phase AC220V or 220V power supply, the value of the power supply is DC24V3A, the normal operating current value is 6A, the main frequency of the programmable controller PLC is 3500+, 2.0GHz; the feeding controller PFC- 52M.

[0041] see figure 1 and Figure 5 A kind of cylindrical lithium battery processing method, its method comprises the following steps:

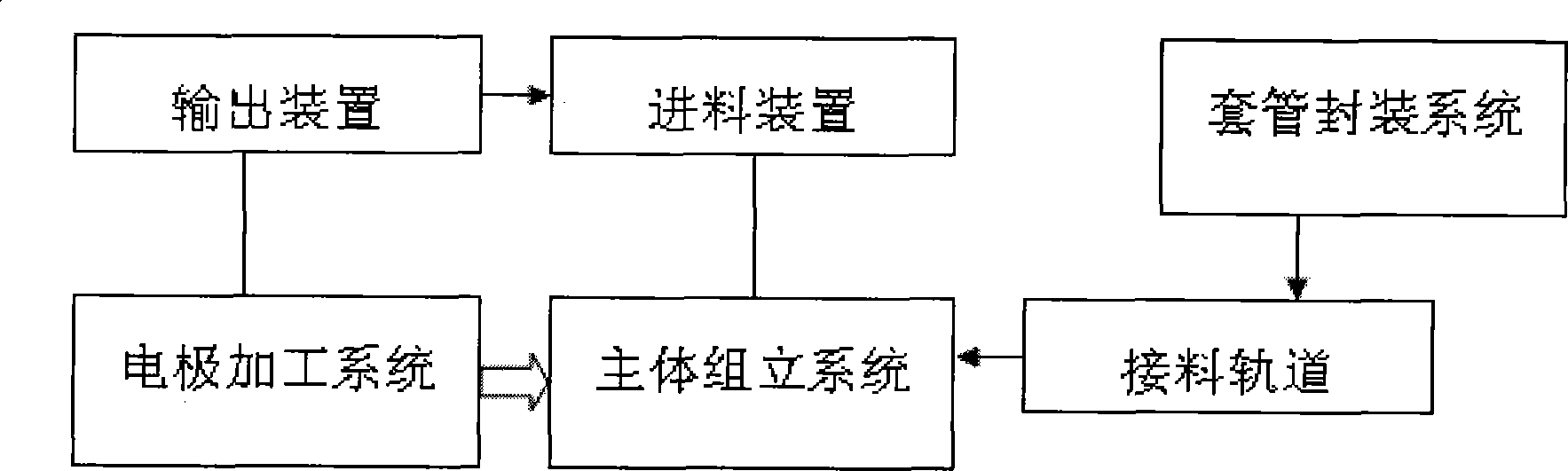

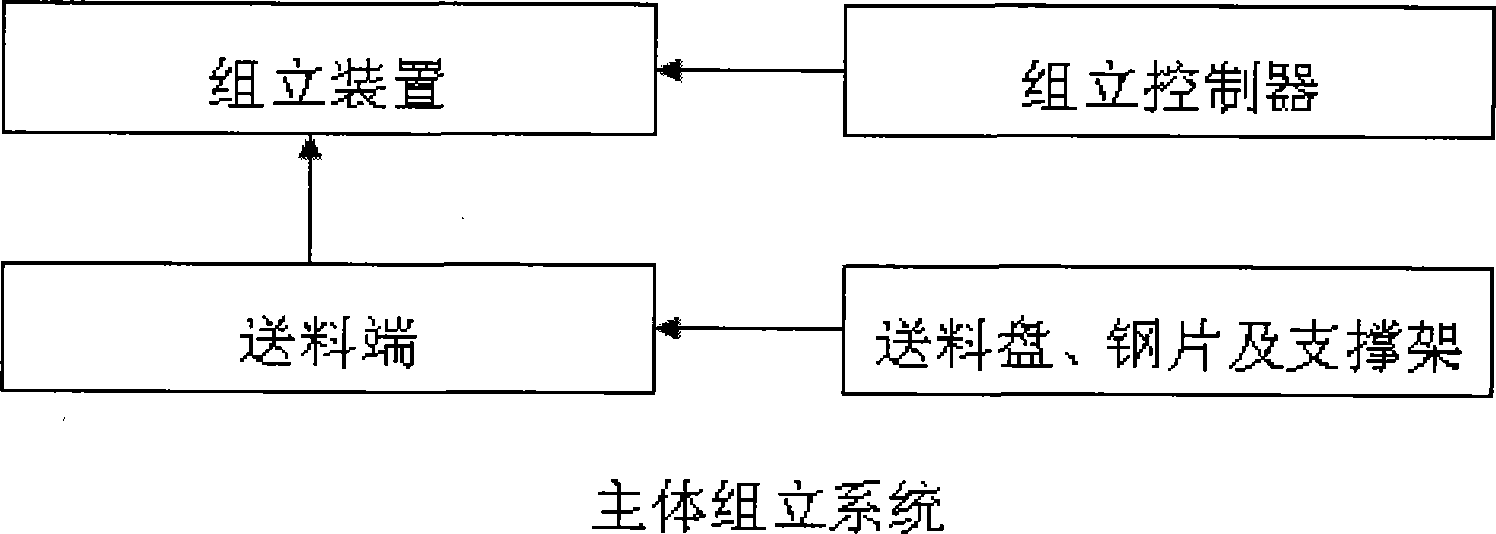

[0042] (1) An electrode processing system, a main body assembly system and a casing packaging system are set; the electrode processing system is provided with an output device and the feeding device provided by the main body assembly system is connected to each other; the casing packaging system is provided with a material receiving track and The main body assembly systems are connected to each other to realize the connection of process control.

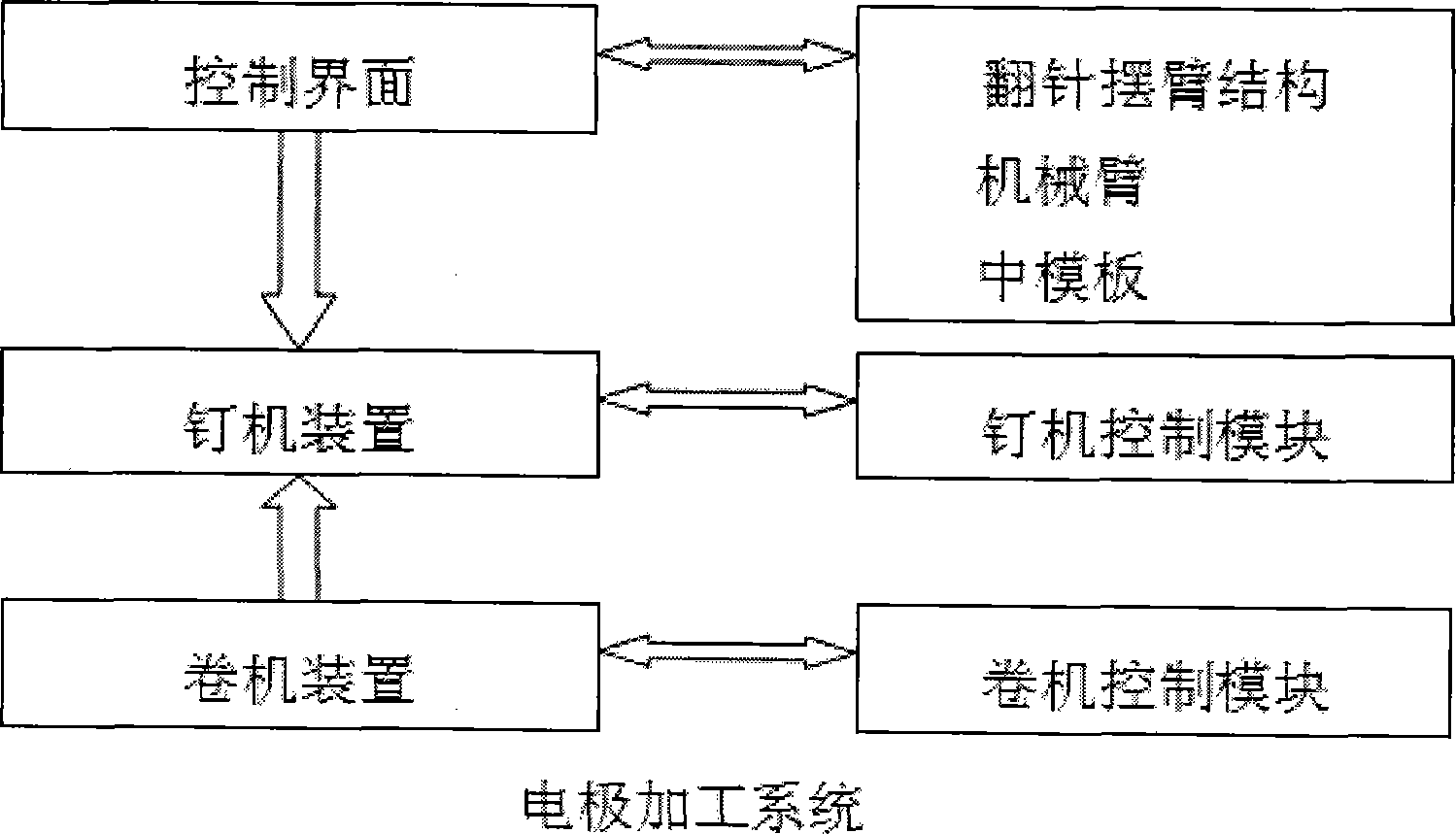

[0043] (2) The electrode processing system is provided with a nailing machine device and a nailing machine...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com