Adjusting type venturi tube double-layer structure atomizing nozzle

A Venturi tube and double-layer structure technology, applied in chemical instruments and methods, dispersed particle separation, separation methods, etc., can solve problems such as poor atomization effect, high energy consumption, easy blockage, etc., and reduce daily maintenance costs , expand the atomization area, and improve the effect of using stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The specific embodiments of the present invention will be described in further detail below, but the embodiments of the present invention are not limited thereto.

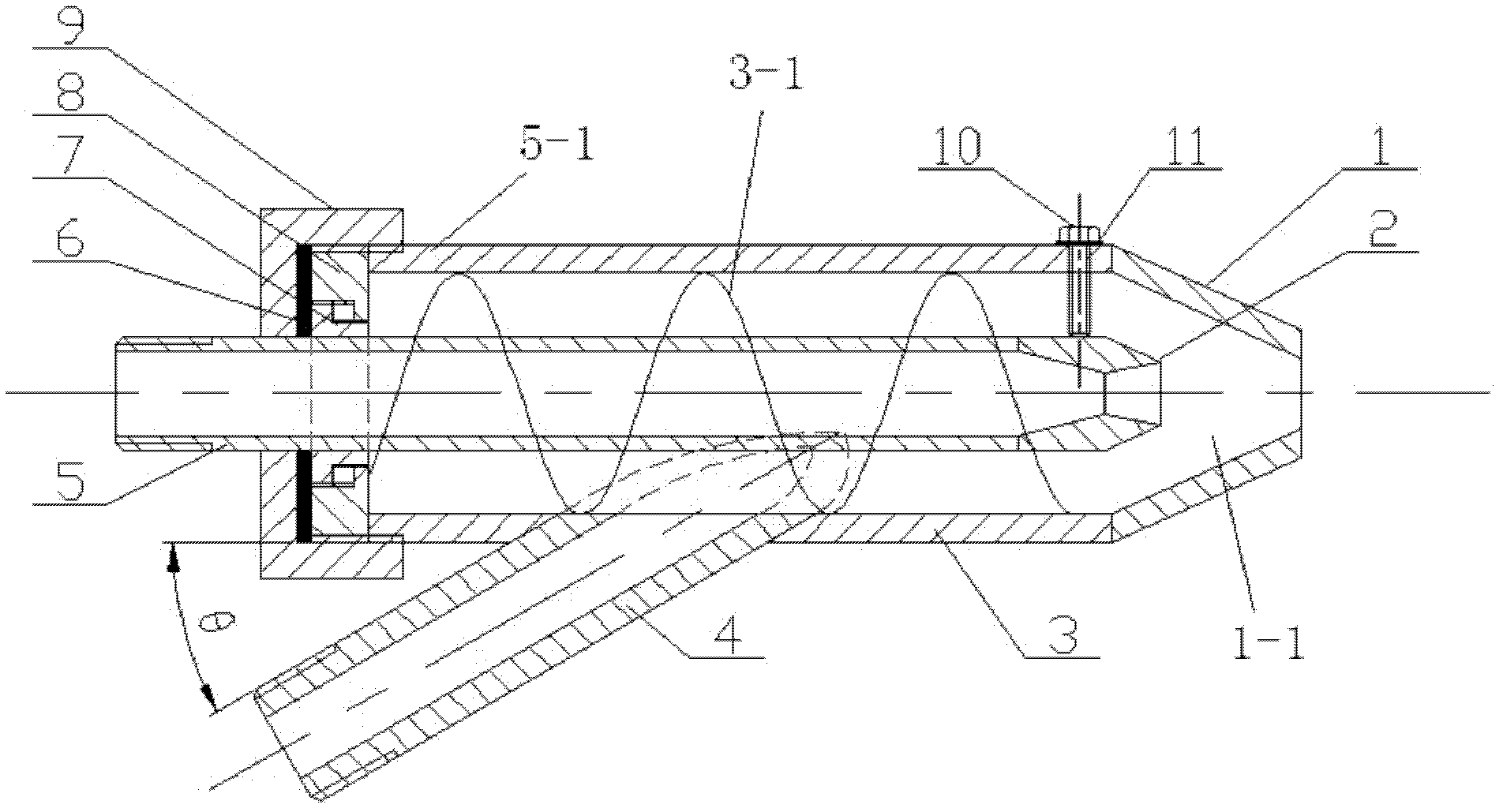

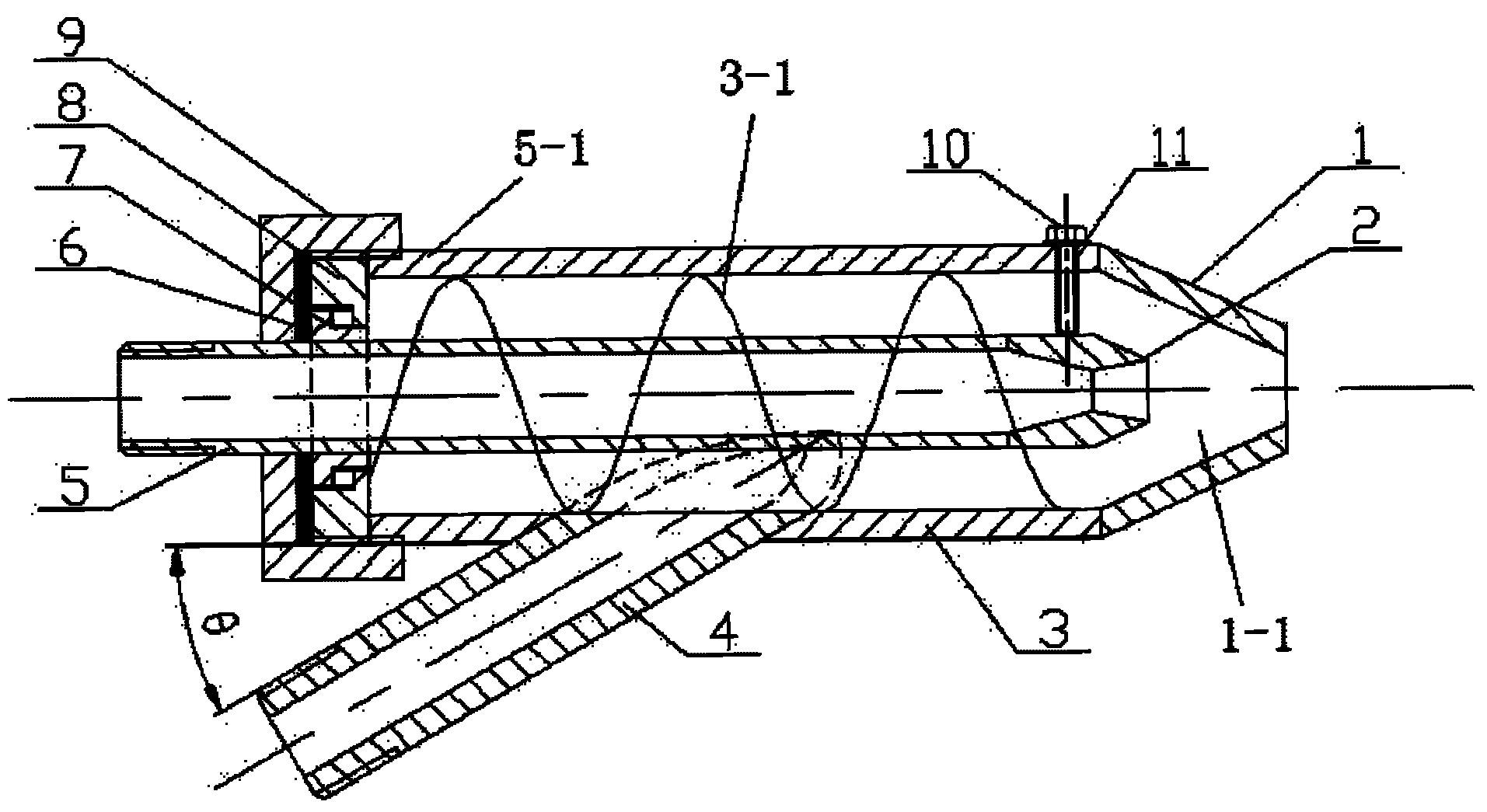

[0029] Such as figure 1 shown. The adjustable Venturi tube double-layer structure atomizing nozzle of the present invention includes a slurry nozzle 1 with an inner tapered end and a gas nozzle 2 with a Venturi tube at the end. The gas nozzle 2 is installed inside the slurry nozzle 1. There is a gap between the outer wall of the gas nozzle 2 and the inner wall of the slurry nozzle 1 (the size of the gap is determined by the diameter of the slurry nozzle 1 and the gas nozzle 2), and the gap constitutes the slurry cavity 3; the outer wall of the slurry nozzle 1 is provided with The slurry enters tube 4. The diameter of the outlet of the gas nozzle 2 should be smaller than the diameter of the outlet of the slurry nozzle 1; the tail end 5-1 of the slurry nozzle 1 and the tail 5 of the gas nozzle 2 are slidingl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com