Method for brazing steel pipe and copper pipe

A brazing method and technology for steel pipes, which are applied in welding media, welding equipment, welding/welding/cutting items, etc., can solve the problems of large welding leakage rate, high silver content in silver brazing filler metal, and difficult operation, etc. The effect of brazing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

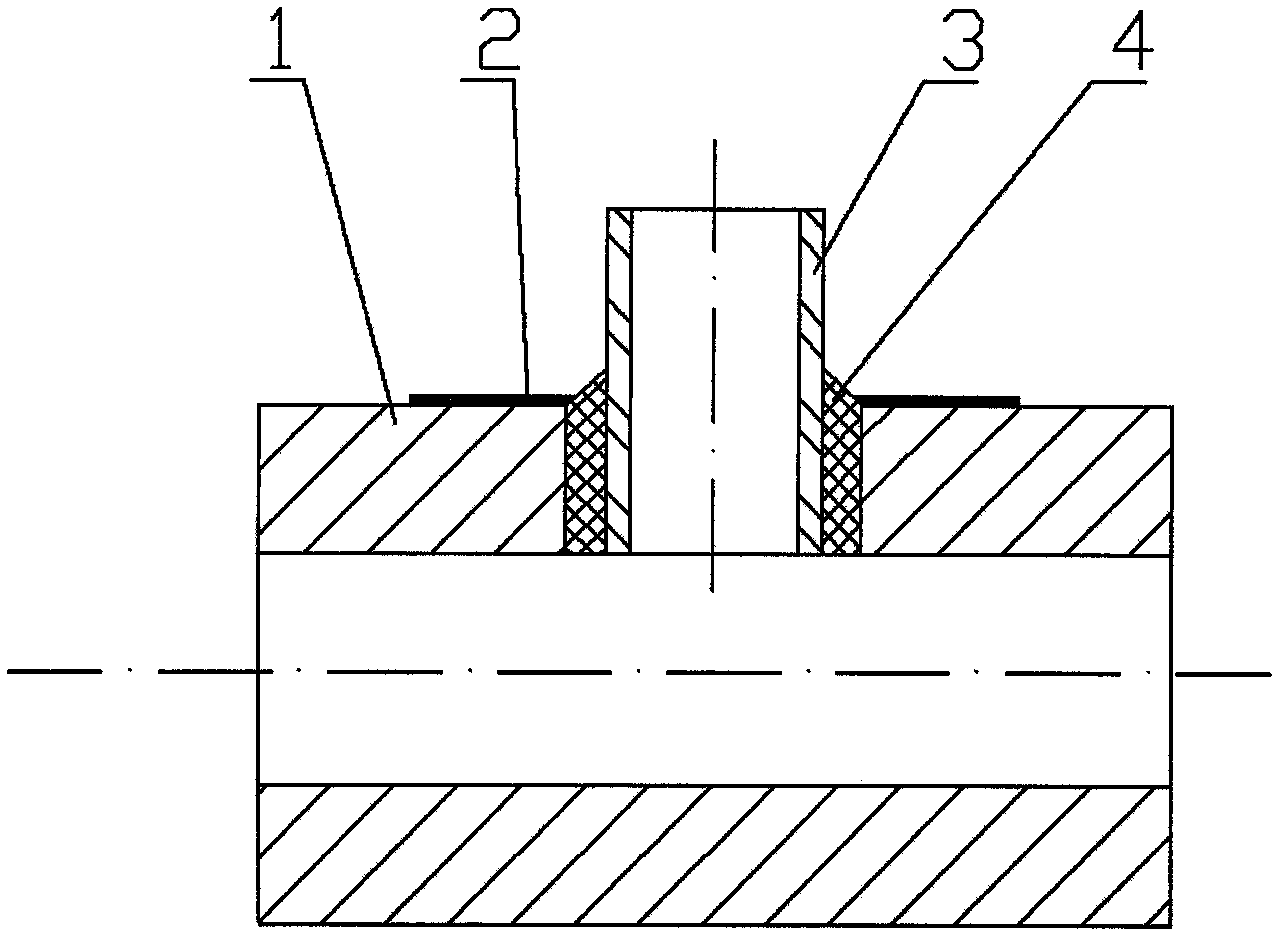

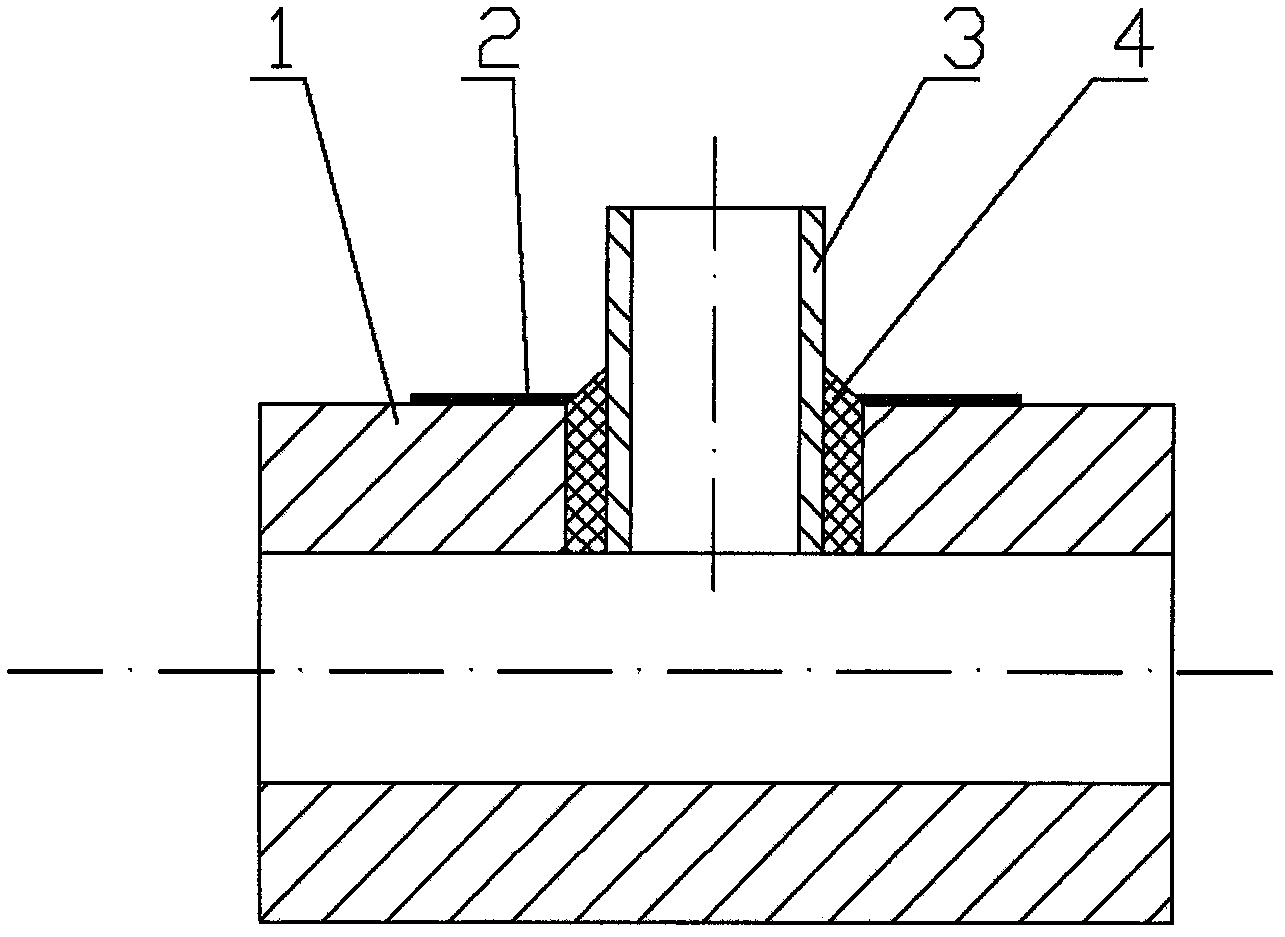

[0015] Example: see figure 1 Shown, a kind of steel pipe and copper pipe brazing method, a, steel pipe 1 selects the steel pipe of surface galvanization for use, and steel pipe 1 surface welding point is coated with a layer of pasty QJ102 welding powder 2;

[0016] b. Heat the welding point of steel pipe 1 and copper pipe 3 according to general brazing requirements, add copper-phosphorus brazing material 4 to the welding point, and let it cool naturally. Generally, brazing requires heating the steel pipe 1 and the copper pipe 3, that is, heating the steel pipe 1 and the copper pipe 3 red, that is to say, heating the welding point of the steel pipe 1 to above 900°C, and heating the welding point of the copper pipe 3 to 800°C. ℃ or more.

[0017] The copper-phosphorus solder 4 is the copper-phosphorus solder specified in the "National Standard of the People's Republic of China—Copper-based Solder". The publication number of "National Standard of the People's Republic of China ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com