A kind of vortex vacuum brazing method

A brazing method and vortex technology, which are applied in welding equipment, metal processing equipment, manufacturing tools, etc., can solve problems affecting the brazing quality of vortex component parts, reducing the qualified rate of vortex components, and unsatisfactory brazing quality, etc. , to achieve the effect of facilitating brazing quality, improving brazing quality, and brazing quality assurance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

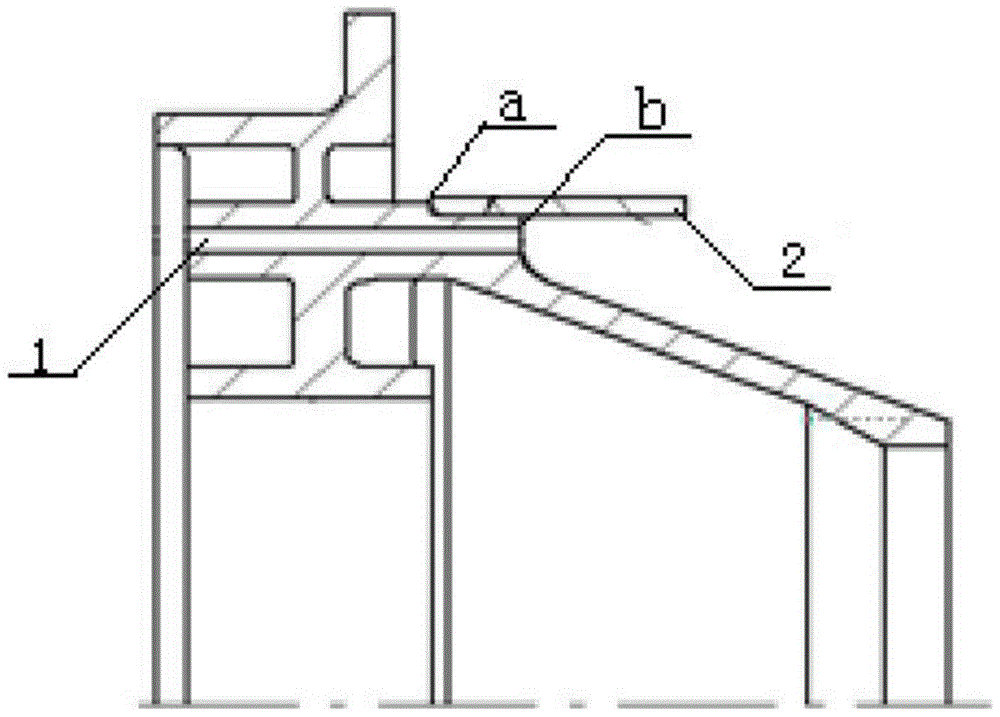

[0031] Such as figure 1 and image 3 Shown, a kind of vortex device vacuum brazing method comprises the following steps:

[0032] (1) Clean the part 4 surface of the vortex assembly, that is, first polish the part 4 surface of the vortex assembly, and then use a reducing agent to clean the part 4 surface of the vortex assembly, and the reducing agent is The mixture prepared by mixing the degreasing agent and hydrochloric acid uniformly according to 1:3, after cleaning for 20 minutes, it is ready for use;

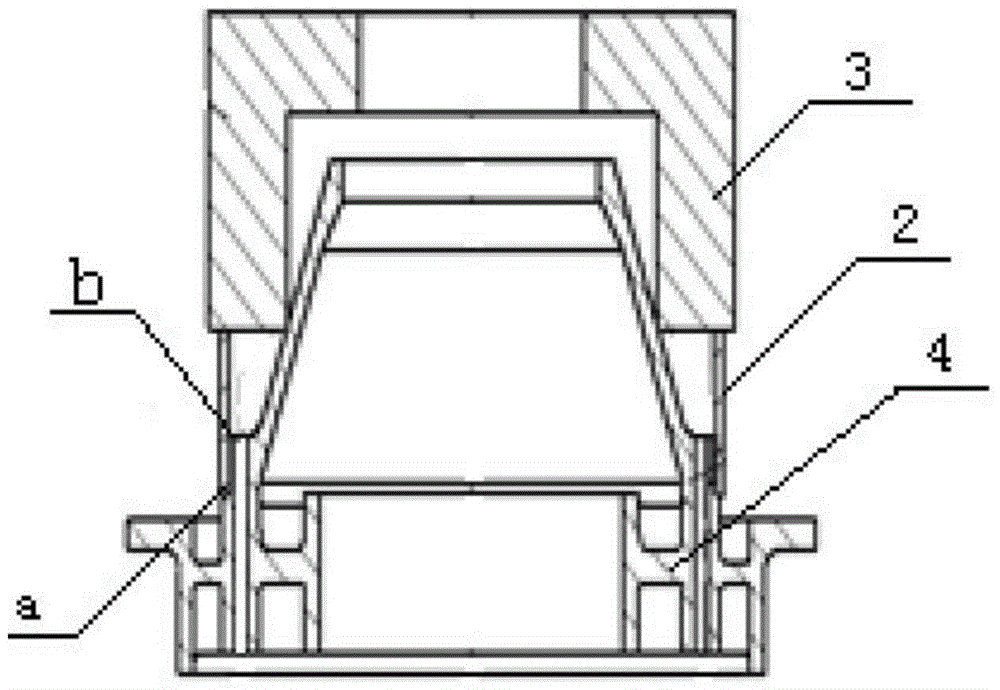

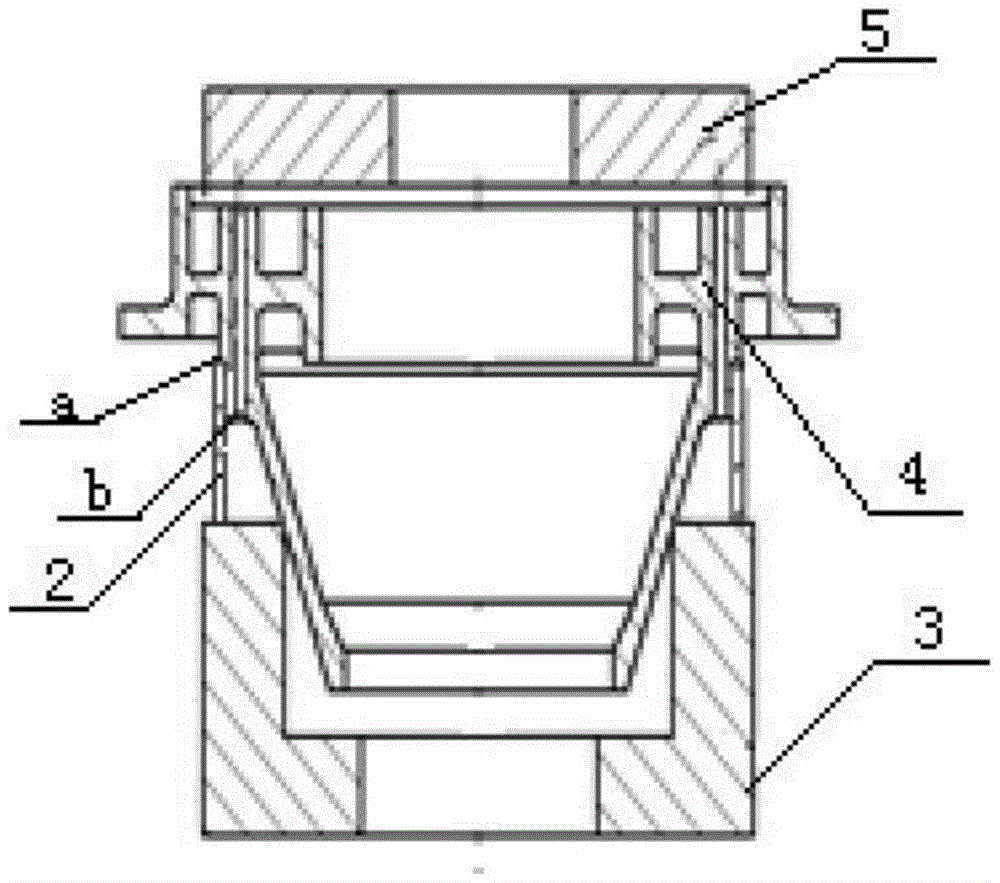

[0033] (2) Add brazing material at a of the part 4 of the vortex assembly obtained in step 1), and use the clamp 3 to cover the outer cover 2 on the vortex assembly part 4, and buckle the part 4 upside down, and then use a fitting on the top. Heavy clamping 5 can complete the brazing assembly of parts 4 of the vortex assembly, ready for use;

[0034] (3) Place the assembled part 4 of the assembly to be brazed obtained in step 2) in the brazing furnace, and when placing i...

Embodiment 2

[0040] A vortex vacuum brazing method, comprising the following steps:

[0041] (1) Clean the part 4 surface of the vortex assembly, that is, first polish the part 4 surface of the vortex assembly, and then use a reducing agent to clean the part 4 surface of the vortex assembly, and the reducing agent is The mixture prepared by mixing the degreasing agent and hydrochloric acid uniformly according to 1:3, after cleaning for 30 minutes, it is ready for use;

[0042] (2) Add brazing material at a of the part 4 of the vortex assembly obtained in step 1), and use the clamp 3 to cover the outer cover 2 on the vortex assembly part 4, and buckle the part 4 upside down, and then use a fitting on the top. Heavy clamping 5 can complete the brazing assembly of parts 4 of the vortex assembly, ready for use;

[0043] (3) Place the assembled part 4 of the component to be brazed obtained in step 2) in the brazing furnace, and when placing it, place the part 4 upside down so that the part b o...

Embodiment 3

[0050] A vortex vacuum brazing method, comprising the following steps:

[0051](1) Clean the part 4 surface of the vortex assembly, that is, first polish the part 4 surface of the vortex assembly, and then use a reducing agent to clean the part 4 surface of the vortex assembly, and the reducing agent is The mixture prepared by mixing the degreasing agent and hydrochloric acid uniformly according to 1:3, after cleaning for 25 minutes, it is ready for use;

[0052] (2) Add brazing material at a of the part 4 of the vortex assembly obtained in step 1), and use the clamp 3 to cover the outer cover 2 on the vortex assembly part 4, and buckle the part 4 upside down, and then use a fitting on the top. Heavy clamping 5 can complete the brazing assembly of parts 4 of the vortex assembly, ready for use;

[0053] (3) Place the part 4 of the assembly to be brazed that is obtained in step 2) in the brazing furnace, and when placing it, place the part 4 upside down so that part b of the pa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com