A low-temperature brazing diamond containing Cr and its solder alloy

A technology of diamond and diamond particles, which is applied in metal processing equipment, grinding devices, manufacturing tools, etc., can solve the problems of diamond abrasive particles and tool substrate heat damage brazing material costs, etc., achieve low vacuum requirements and avoid graphitization , The effect of reducing the cost of brazing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

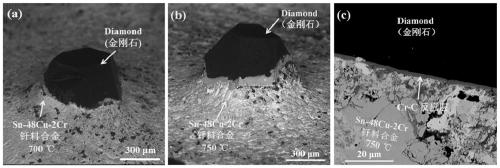

[0022] Please check figure 1 , a kind of solder alloy of the present embodiment is the mixed powder of Sn-48Cu-2Cr (wt.%); Carry out the low-temperature brazing diamond operation containing Cr with it as follows:

[0023] Take by weighing 21.33 grams of pure Sn, 72 grams of Cu-40wt.% Sn pre-alloyed powder, and 6.667 grams of Cu-30wt.% Cr pre-alloyed powder, and mix uniformly in a mixer so that the element ratio is Sn-48Cu-2Cr( wt.%) mixed powder. The brazing filler metal alloy powder that makes with this is respectively in vacuum tube type furnace (less than 5.0 * 10 -3 Pa) at 700 and 750 °C for 60 minutes to weld diamond particles with a particle size of 30 / 35, and the solder alloy and diamond particles form a good connection. figure 1 It corresponds to the macroscopic morphology and interface microscopic morphology of diamond solder joints. The solder climbed up on the diamond surface to form a crater morphology, and a Cr-C reaction layer was formed at the interface, indi...

Embodiment 2

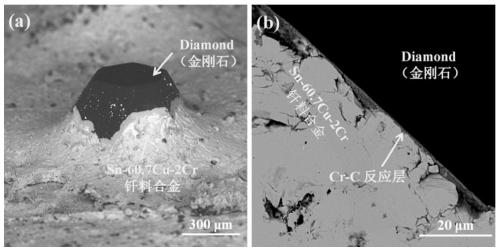

[0025] Please check figure 2 , a kind of solder alloy of the present embodiment is the mixed powder of Sn-60.7Cu-2Cr (wt.%); Carry out the low-temperature brazing diamond operation containing Cr with it as follows:

[0026] Weigh 93.333 grams of Cu-40wt.% Sn pre-alloyed powder and 6.667 grams of Cu-30wt.% Cr pre-alloyed powder respectively, and mix them uniformly in a mixer to be Sn-60.7Cu-2Cr (wt.%) Mix powder. The brazing filler metal alloy powder that makes with this is in vacuum tube type furnace (less than 5.0 * 10 -3 Weld diamond particles with a particle size of 30 / 35 in Pa) at 750°C for 60 minutes, and the solder alloy and diamond particles form a good connection. figure 2 It corresponds to the macroscopic morphology and interface microscopic morphology of diamond solder joints. The Cr-C reaction layer is formed at the interface, indicating that the brazing filler metal and diamond have chemical metallurgical connection.

Embodiment 3

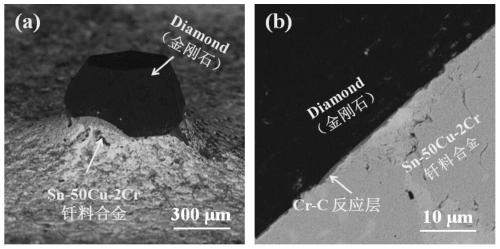

[0028] Please check image 3 , a kind of solder alloy of the present embodiment is the mixed powder of Sn-50Cu-2Cr (wt.%); Carry out the low-temperature brazing diamond operation containing Cr with it as follows:

[0029] Weigh 17.778 grams of pure Sn powder, 75.555 grams of Cu-40wt.% Sn pre-alloyed powder, and 6.667 grams of Cu-30wt.% Cr pre-alloyed powder, and mix them uniformly in a mixer so that the element ratio is Sn-60.7Cu-2Cr (wt.%) mixed powder. The brazing filler metal alloy powder that makes with this is in vacuum tube type furnace (less than 5.0 * 10 -3 Weld diamond particles with a particle size of 30 / 35 in Pa) at 750°C for 30 minutes, and the solder alloy and diamond particles form a good connection. image 3 It corresponds to the macroscopic morphology and interface microscopic morphology of diamond solder joints. The Cr-C reaction layer is formed at the interface, indicating that the brazing filler metal and diamond have chemical metallurgical connection.

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com