A kind of gold-tin system lead-free solder and preparation method thereof

A technology of lead-free solder and solder sheet, applied in welding equipment, metal processing equipment, welding/cutting media/materials, etc., can solve problems such as processing difficulties, improve strength and plasticity, improve performance, and suppress intermetallic compounds The effect produced

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

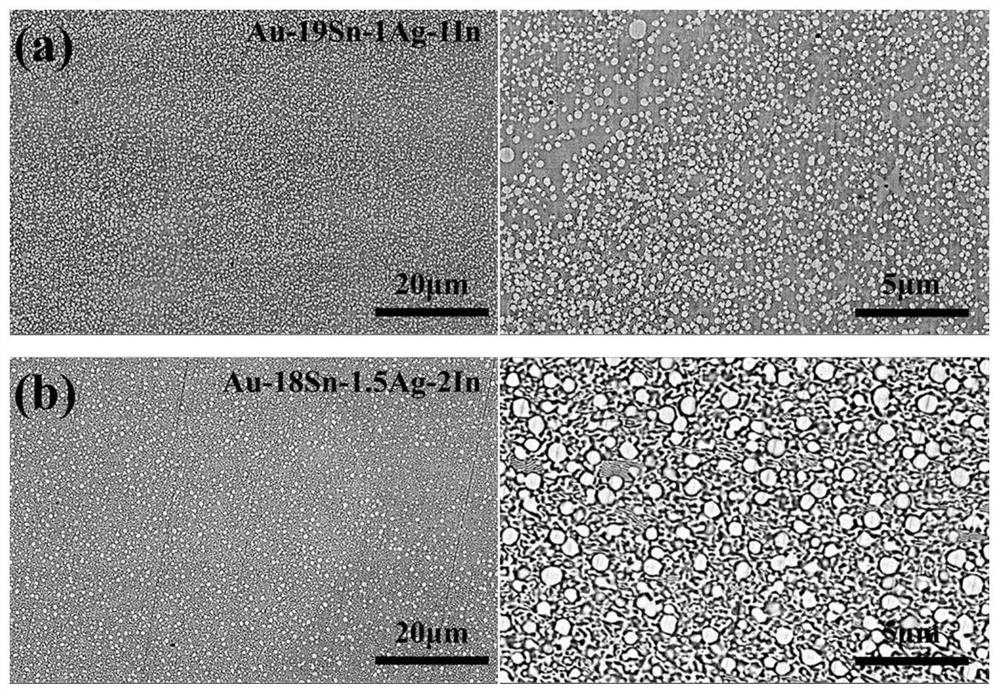

[0029] Preparation of Au-19Sn-1Ag-1In alloy:

[0030] ① Put the weighed 39.5gAu and 9.5gSn into the vacuum non-consumable arc melting furnace in proportion, turn on the circulating water, turn on the mechanical pump, and start vacuuming;

[0031] ②After the vacuum is pumped below 5Pa, turn on the molecular pump and continue to pump the vacuum to 4*10 -3 Below Pa;

[0032] ③ Open the baffle valve, close the molecular pump, and fill with argon to 0.5 atmospheres;

[0033] ④ Turn on the smelting power supply, move the W electrode to a height of 4mm from the middle titanium ingot, and strike the arc;

[0034] ⑤After the titanium ingot melts and absorbs the impurity gas, move the arc to the crucible of Au and Sn, the melting current is between 300A and smelting for 30s;

[0035] ⑥ Turn on the magnetic stirring power supply, control the stirring current between 10A, and continue melting for 60s;

[0036] ⑦Turn off the arc, and turn the ingot with a control spoon after cooling; ...

Embodiment 2

[0044] Preparation of Au-18Sn-1.5Ag-2In alloy:

[0045] ① Put the weighed 39.25gAu and 9gSn into the vacuum non-consumable arc melting furnace in proportion, turn on the circulating water, turn on the mechanical pump, and start vacuuming;

[0046] ②After the vacuum is pumped below 5Pa, turn on the molecular pump, and continue to pump the vacuum to below 4*10-3Pa;

[0047] ③Open the flapper valve, close the molecular pump, and fill with argon to 0.45 atmospheres;

[0048] ④ Turn on the smelting power supply, move the W electrode to a height of 4mm from the middle titanium ingot, and strike the arc;

[0049] ⑤After the titanium ingot melts and absorbs the impurity gas, move the arc to the crucible of Au and Sn, the melting current is between 250A and smelting for 30s;

[0050] ⑥ Turn on the magnetic stirring power supply, control the stirring current between 15A and continue melting for 60s;

[0051] ⑦Turn off the arc, and turn the ingot with a control spoon after cooling;

...

Embodiment 3

[0058] Preparation of Au-19.9Sn-0.8Ag-1.1In alloy:

[0059] ① Put the weighed 39.1gAu and 9.95gSn into the vacuum non-consumable arc melting furnace in proportion, turn on the circulating water, turn on the mechanical pump, and start vacuuming;

[0060] ②After the vacuum is pumped below 5Pa, turn on the molecular pump, and continue to pump the vacuum to below 4*10-3Pa;

[0061] ③Open the baffle valve, close the molecular pump, and fill with argon to 0.55 atmospheres;

[0062] ④ Turn on the smelting power supply, move the W electrode to a height of 4mm from the middle titanium ingot, and strike the arc;

[0063] ⑤After the titanium ingot melts and absorbs the impurity gas, move the arc to the crucible of Au and Sn, the melting current is between 280A and smelting for 30s;

[0064] ⑥ Turn on the magnetic stirring power supply, control the stirring current between 10A, and continue melting for 60s;

[0065] ⑦Turn off the arc, and turn the ingot with a control spoon after cooli...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| yield stress | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com