Sealing method of quartz substrate with metal electrode and special clamp thereof

A quartz substrate and metal electrode technology, applied in the field of non-metal welding, can solve the problems of large internal stress at the interface, cracking, low thermal expansion coefficient of quartz, etc., to avoid uneven pressure, reduce welding temperature, and avoid internal stress.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described in detail below in conjunction with specific drawings, but the protection scope of the present invention should not be limited thereby.

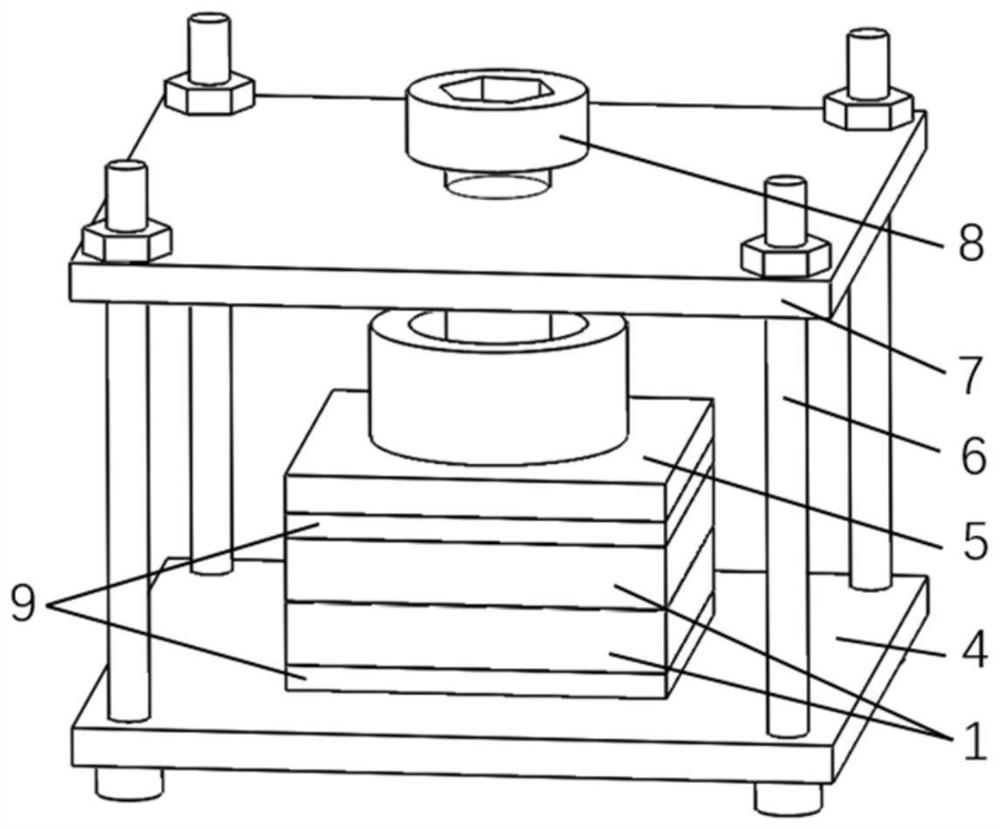

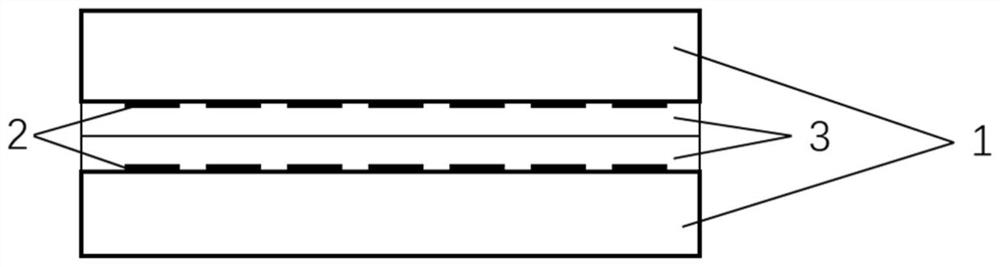

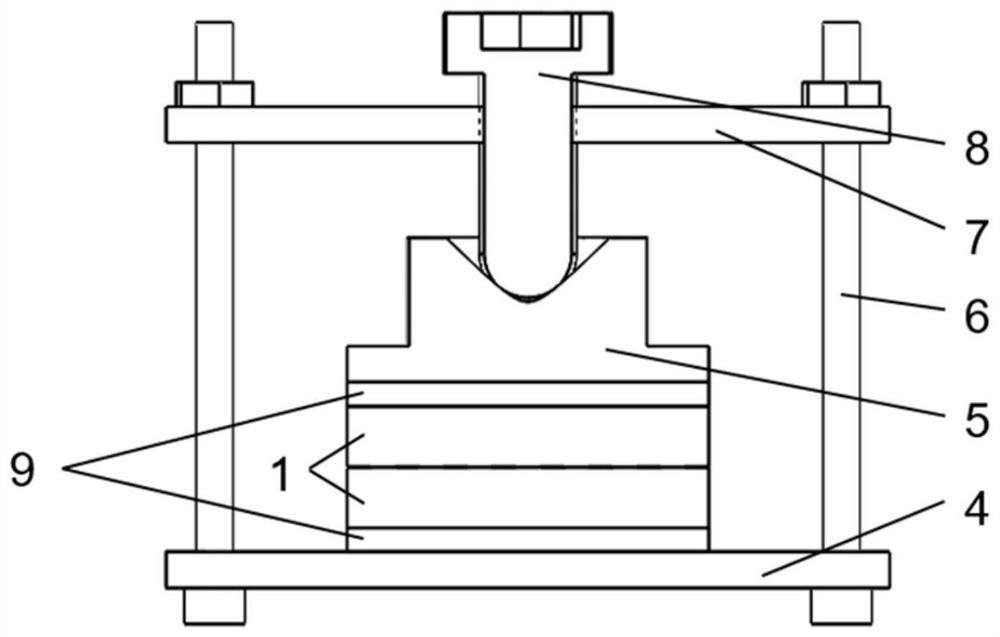

[0036] see Figure 1-Figure 3 , figure 1 For the present invention implements the use state diagram of the special fixture of the encapsulation method of the quartz substrate with metal electrodes, figure 2 is the cross-sectional view of the welding surface of the welded quartz substrate, image 3 It is the sectional view of the welded quartz substrate and the special fixture. As shown in the figure, a sealing method for a quartz substrate with a metal electrode uses an evaporation method to uniformly plate glass solder on the electrode layer 2 of a quartz substrate 1 with a metal electrode to form a glass solder layer 3; The glass solder layers 3 of the two connected quartz substrates 1 are in contact, and pressure is applied so that the glass solder layers 3 are in close contact; t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com