Welding method and product of superconducting tape in superconducting cable accessories

A technology for superconducting cables and welding methods, applied in welding equipment, welding/welding connections, conductors, etc., can solve problems such as unsafety and difficult quality assurance, and achieve the effect of meeting electrical conductivity requirements and good low temperature performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

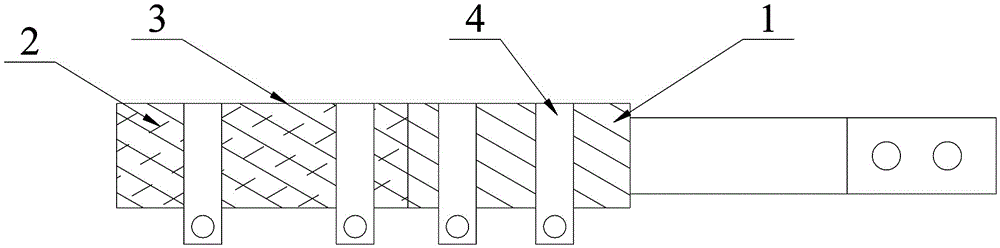

[0023] According to accompanying drawing, the welding method and product thereof of superconducting tape in a kind of superconducting cable accessory of the present invention, its welding method technological process is as follows:

[0024] (1) Treatment of the welding surface: including the surface treatment of the cable head of the circular copper conductor 1 and the superconducting tape, smoothing, cleaning and descaling of the welding surface, and coating with flux. The flux is commercially available, and you can choose Jinji brand solder paste produced by Shanghai Jinji Solder Paste Factory or other brands of flux.

[0025] (2) Binding and fixing: The welding surface of the circular copper conductor is flat and close to the first layer of low-temperature welding film, and the cover is flat and close, and the first layer of superconducting tape of the cable is evenly arranged on the welding surface of the circular copper conductor First, tie the first layer of superconduct...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistance | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com