A kind of solder paste with stable performance and preparation method thereof

A solder paste and stable technology, applied in the field of solder paste with stable performance and its preparation, can solve the problems of device damage, flow, and inability to maintain the shape of solder joints, so as to improve temperature fatigue resistance and mechanical fatigue resistance, avoid Viscosity increases and the effect of avoiding separation of copper powder

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

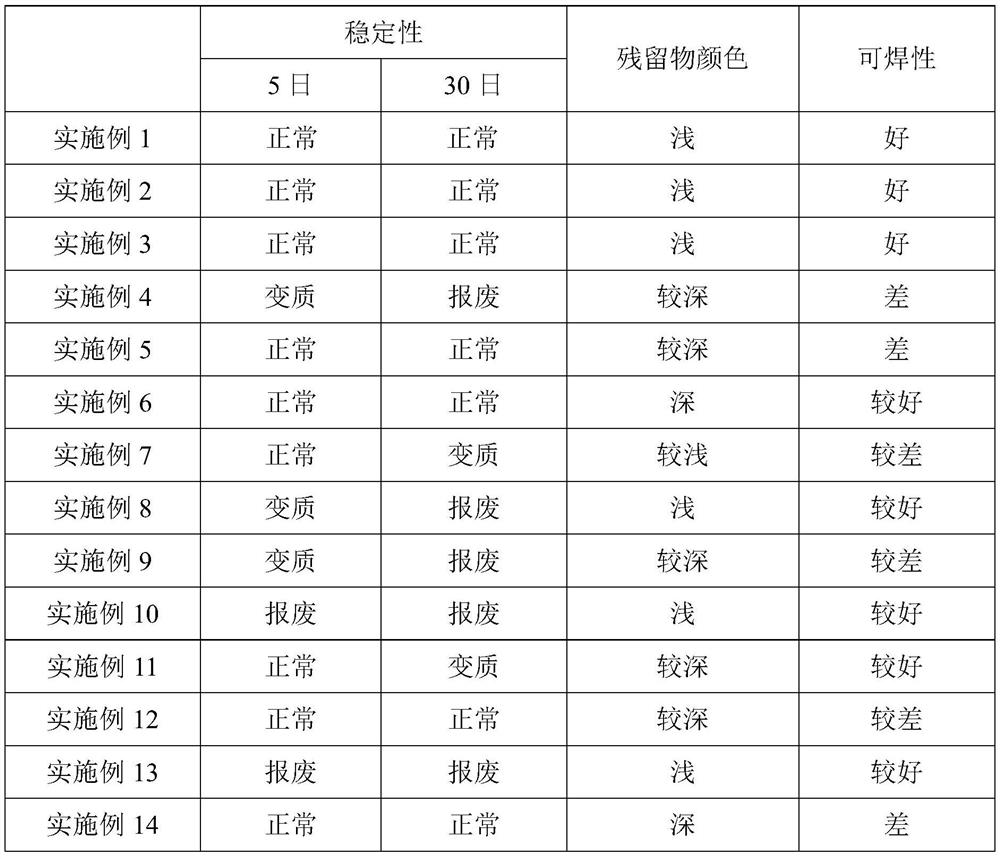

Examples

preparation example Construction

[0033] The preparation method of described SAC 305 alloy powder, comprises the steps:

[0034] (1) Melt the prepared alloy SAC 305 in the melting furnace, and then slowly drop it onto the high-speed turntable of the centrifugal atomization device. Under the condition of nitrogen protection, the liquid solder is rotated at high speed and flew out, and is cooled in parallel into fine particles ;

[0035] (2) After sieving, the alloy powder whose particle size distribution conforms to the ipc j-std-006 standard is selected to obtain the SAC305 alloy powder.

[0036] Nano metal powder

[0037] In one embodiment, the nano metal powder is pure copper powder and / or bronze powder.

[0038] In a preferred embodiment, the nano metal powder is pure copper powder.

[0039] In a preferred embodiment, the particle size of the pure copper powder is 20-100 nm.

[0040] In a preferred embodiment, the particle size of the pure copper powder is 40-60 nm.

[0041] In a preferred embodiment...

Embodiment 1

[0093] Embodiment 1 provides a kind of solder paste with stable performance, and described solder paste comprises tin solder alloy, nanometer metal powder, flux paste; The mass ratio of described nanometer metal powder and tin solder alloy is 1:8; The content of solder paste is 10wt%;

[0094] The tin solder alloy is SAC 305 alloy powder; the SAC 305 alloy powder is self-made;

[0095] The preparation method of described SAC 305 alloy powder, comprises the steps:

[0096] (1) Melt the prepared alloy SAC 305 in the melting furnace, and then slowly drop it onto the high-speed turntable of the centrifugal atomization device. Under the condition of nitrogen protection, the liquid solder is rotated at high speed and flew out, and is cooled in parallel into fine particles ;

[0097] (2) After sieving, the alloy powder whose particle size distribution meets the ipc j-std-006 standard is selected to obtain the SAC305 alloy powder;

[0098] The nano metal powder is pure copper powde...

Embodiment 2

[0113] Embodiment 2 provides a kind of solder paste with stable performance, and described solder paste comprises tin solder alloy, nanometer metal powder, flux paste; The mass ratio of described nanometer metal powder and tin solder alloy is 1:14; The content of solder paste is 20wt%;

[0114] Described tin solder alloy is with embodiment 1;

[0115] The nano metal powder is pure copper powder; the particle diameter of the pure copper powder is 60nm;

[0116] In parts by weight, the solder paste includes 40 parts of disproportionated rosin, 35 parts of solvent, 13 parts of polybasic organic acid, 12 parts of unsaturated acid anhydride, 4 parts of amide wax, and 4 parts of anti-aging agent;

[0117] The disproportionated rosin is dihydroabietic acid (CAS No. 19402-28-9);

[0118] Described solvent is diethylene glycol butyl ether (CAS number is 112-34-5);

[0119] The unsaturated acid anhydride is phthalic anhydride;

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com