Processing method for tiny thin-wall part

A technology of thin-walled parts and processing methods, which is applied in the processing field of tiny thin-walled structural parts, can solve problems such as the inability to accurately process metal tiny thin-walled parts, and achieve the effect of realizing micro-ultra-precision machining and ensuring accuracy indicators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

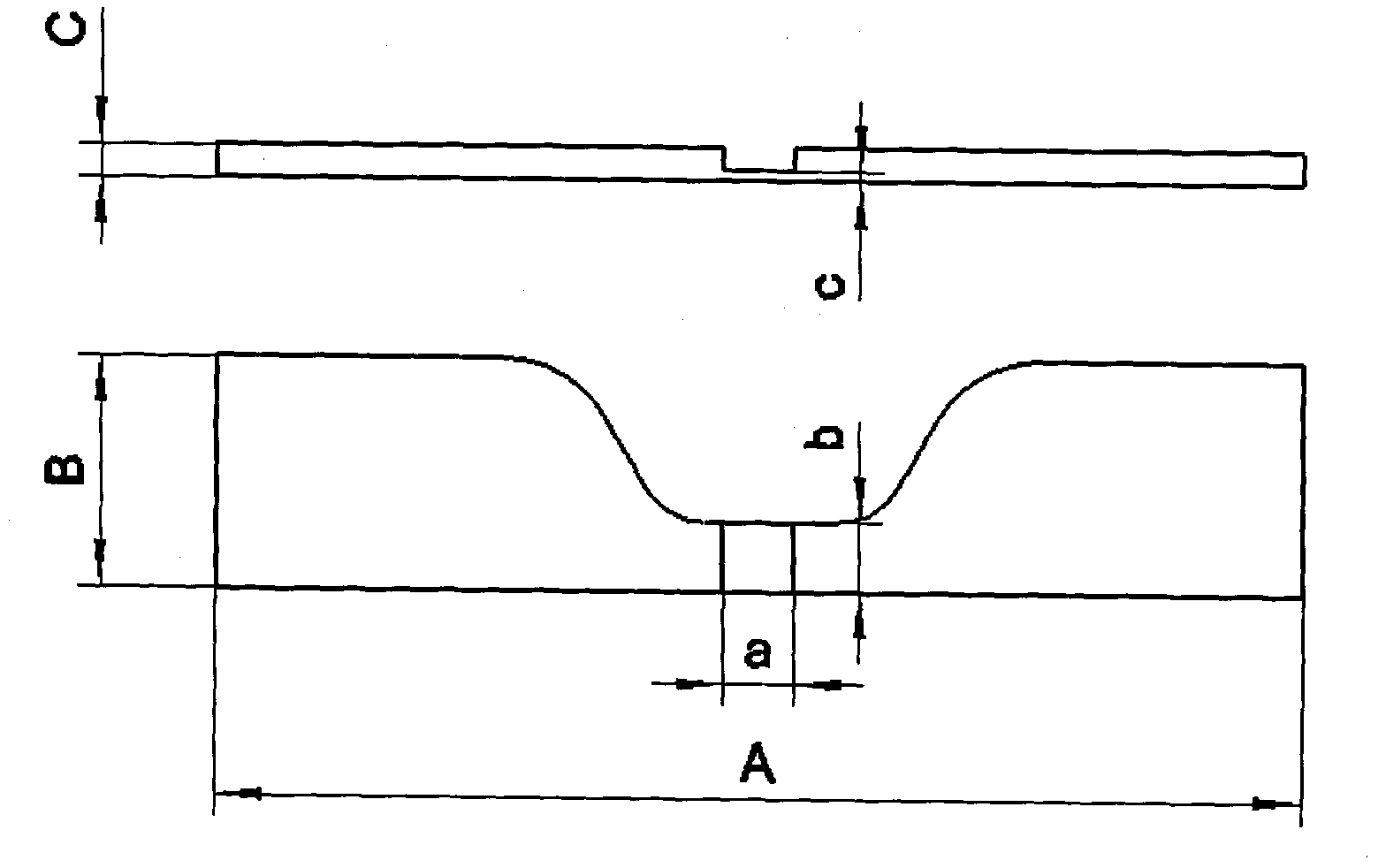

[0061] The small thin-walled structural parts are small in size, such as figure 2 As shown, the overall size is A×B×C is 3mm×0.6mm×0.08mm, and the thin-walled feature size a×b×c is 200μm×180μm×(10±1)μm. The tiny parts are thin-walled, and there are three difficulties in micro-milling: one is the clamping and positioning of the tiny parts;

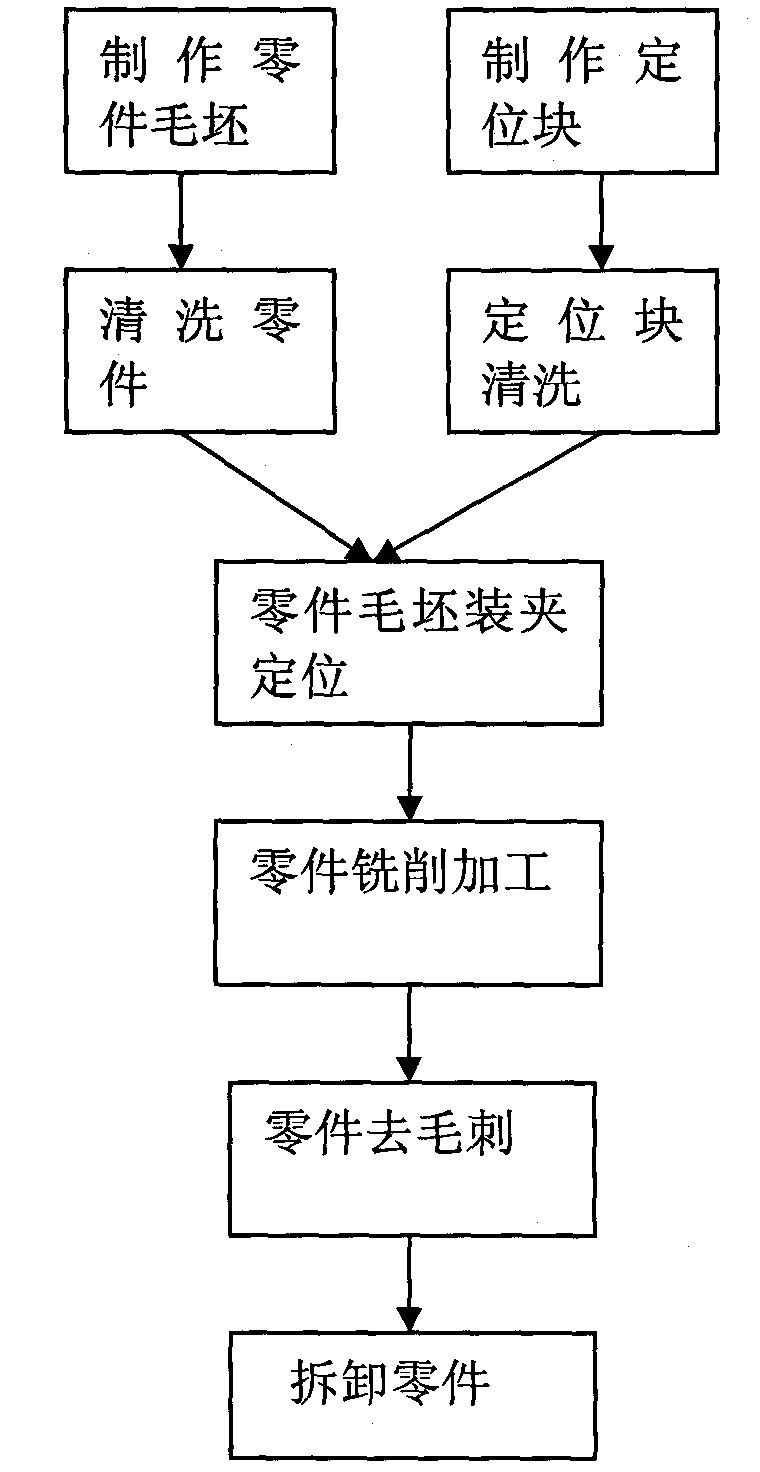

[0062] The specific solution steps are as follows:

[0063] (1) Making positioning blocks and parts blanks

[0064] a) Make a positioning block

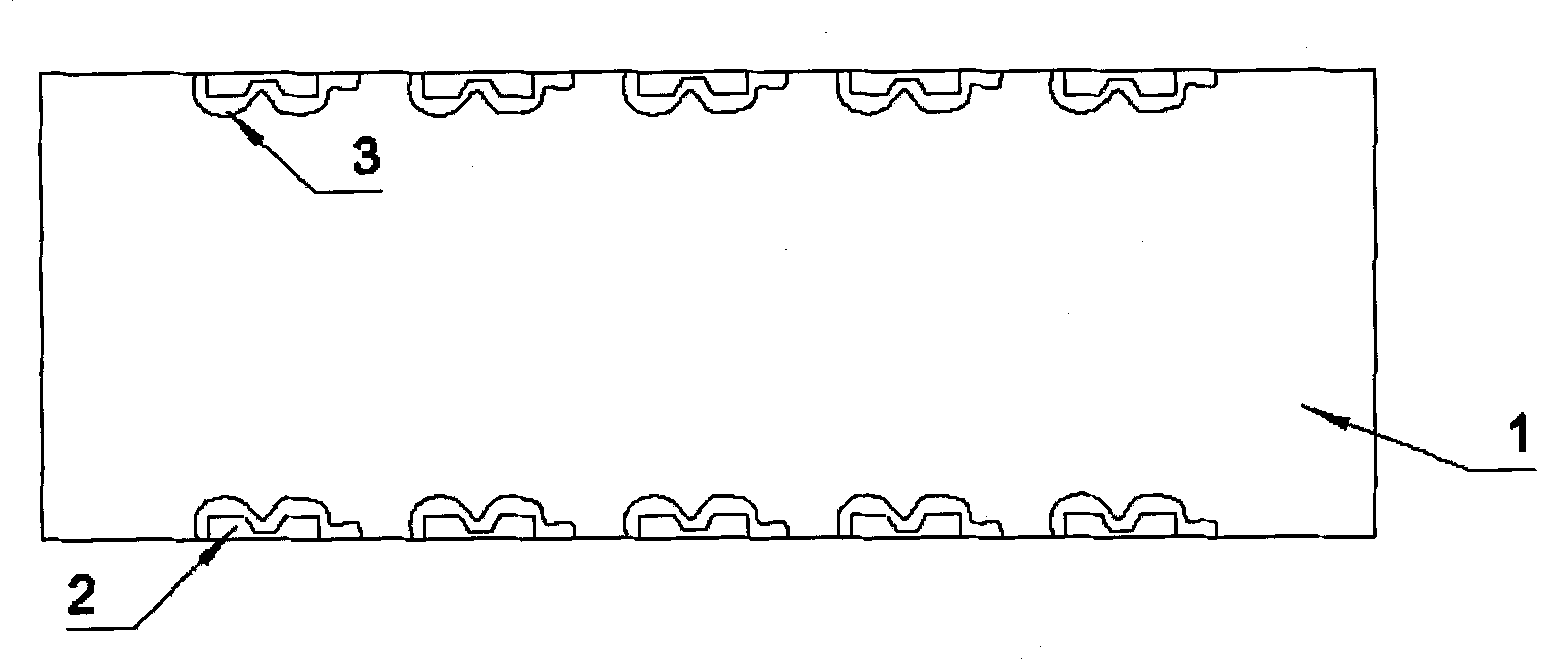

[0065] Make the positioning block 1, as the positioning surface of the part blank 2, for the clamping and positioning of the part blank 2. The positioning block 1 is a cuboid with a size of 28mm×25mm×(10±0.01)mm, the parallelism of the positioning surface is 0.005mm, the flatness is 0.003mm, and sharp edges are maintained. The positioning block can be processed by precision flat grinding machine to meet the requirements;

[0066] b) Making part blanks

[0067] Precise slow wire cutting is u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com