Injection mould device with spray nozzle self-centering device

An automatic centering and injection mold technology, which is applied in the field of hot runner injection molds, can solve the problems of long installation time, time required for alignment and debugging, high requirements for workers' operation proficiency, and difficulty in correct installation, so as to simplify assembly work, The effect of shortening the assembly cycle and reducing the installation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

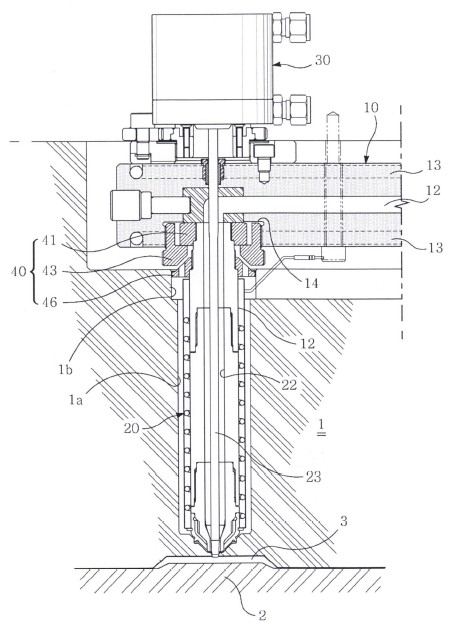

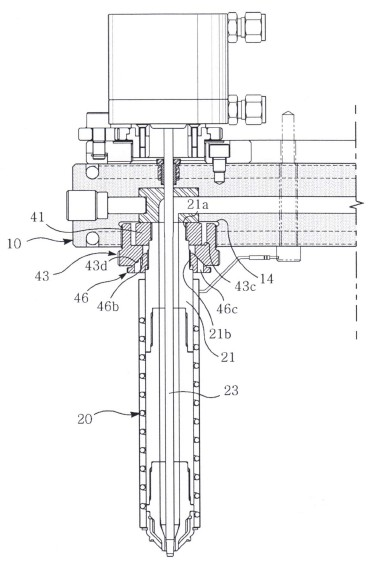

[0024] Example 1: see figure 1 As shown, an injection mold equipped with an automatic nozzle centering device includes a fixed mold 1, a movable mold 2, a mold row cavity 3 between the fixed mold 1 and the movable mold 2, and is provided in the fixed mold 1. The upper manifold 10 is provided with one or more resin supply channels 12 through which molten resin supplied from the outside can pass, and the molten resin passing through the resin supply channel 12 is maintained at an appropriate temperature and arranged on the resin supply A plurality of heating wire rods 13 around the channel 12; a nozzle device 20 that selectively supplies the molten resin through the resin supply channel 12 to the mold row cavity 3 is installed in the nozzle installation hole 1a of the fixed mold 1.

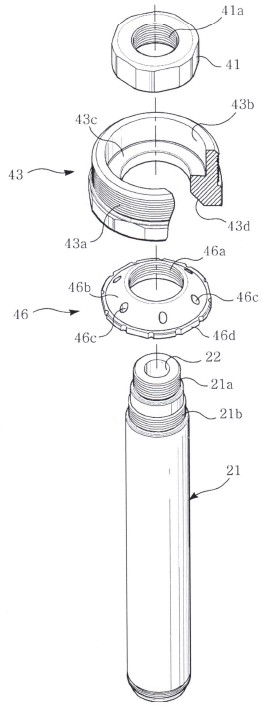

[0025] Such as Figure 1~2 As shown, the nozzle device 20 includes a nozzle body 21 with a resin channel 22 inside. The nozzle valve needle 23 in the resin channel 22 opens the outlet of the resin chan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com