Processing method for strip Fresnel lens

A Fresnel lens and processing method technology, applied to other household appliances, optical components, household appliances, etc., can solve the problems of high cost, low quality accuracy, easy to produce scattering, etc., and achieve cost reduction, simple process, and fast speed. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] 1. Take 500kg of transparent and anti-aging PVC resin, put it into the kneader and knead it for about 30 minutes, transfer it to the internal mixer for plasticization for 10 minutes, and then enter the feeder for plasticization and filtration.

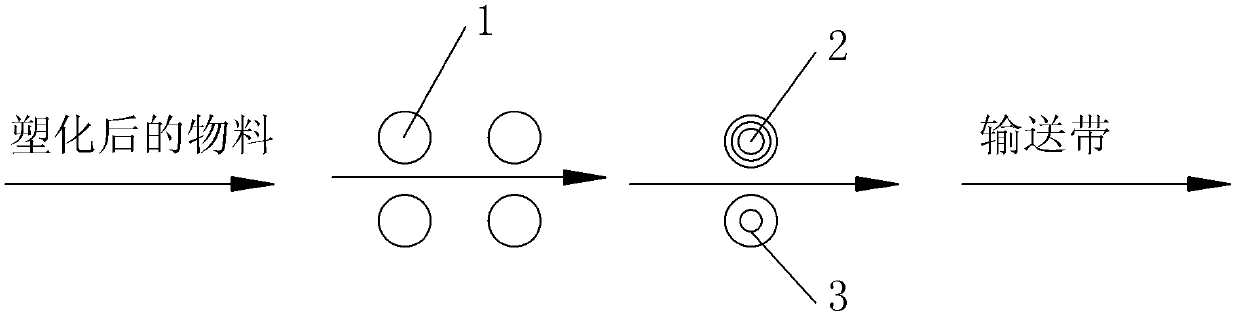

[0024] 2. The basic plasticized plastic is rolled and formed in a hot roller.

[0025] The material enters a four-roller calender and is calendered into sheets, and the linear speed of the calender rollers of the calender is 120m / min.

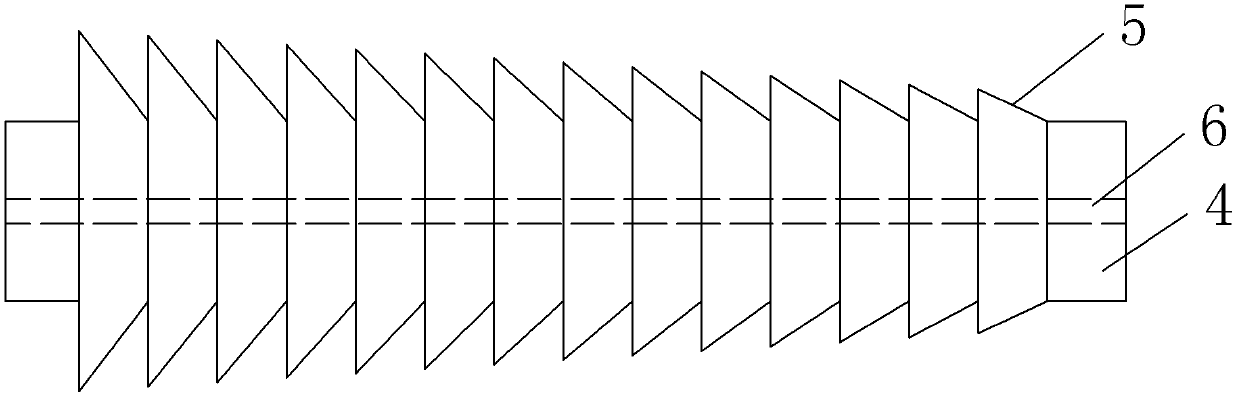

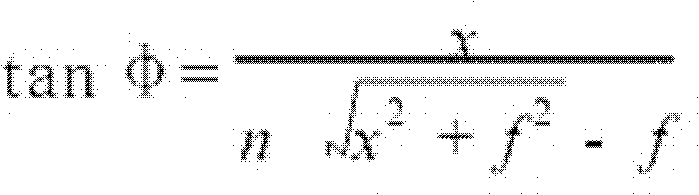

[0026] 3. The calendered sheet is pressed with a Fresnel pattern roller and a smooth roller, and is cooled while pressing, so that the temperature of the Fresnel pattern sheet is cooled to about 50°C. Excessive cooling (less than 30°C), water droplets will appear on the surface of Fresnel toothed roller and smooth roller, which will also affect product quality; the line speed of Fresnel toothed roller and smooth roller is 200m / min, and the Fresnel toothed roller The linear speed of the roller an...

Embodiment 2

[0040] 1. Take 500kg of transparent, anti-aging and anti-ultraviolet PET, and add it into a twin-screw extruder to extrude and plasticize.

[0041] 2. The basic plasticized plastic is rolled and formed in a hot roller.

[0042] Then the material enters a four-roller calender and is calendered into sheets, and the linear speed of the calender rolls of the calender is 175m / min.

[0043] 3. The calendered sheet is pressed by the Fresnel toothed roller and the smooth roller, and cooled while pressing, so that the temperature of the Fresnel pattern sheet is cooled to about 45°C; if the cooling is excessive, the Fresnel toothed roller and the smooth roller The appearance of water droplets on the surface of the roller will also affect the product quality; the linear speed of the Fresnel toothed roller and the smooth roller is 250m / min, and the linear speed of the Fresnel toothed roller and the smooth roller should not be too large, otherwise cold stretching will occur. The internal ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| velocity | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com