Hydraulic braking system of container front crane

A technology of hydraulic braking and reach stacker, applied in hydraulic braking transmission device, foot start device, etc., can solve the problems of brake life influence, failure, unstable braking torque, etc., to avoid pressure fluctuation and brake failure, The effect of high work efficiency and novel structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

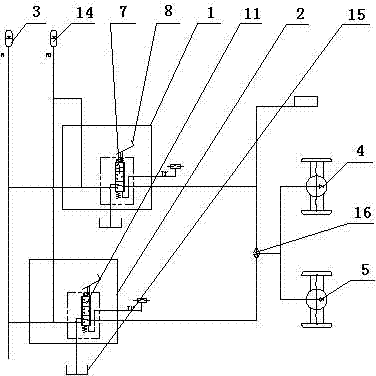

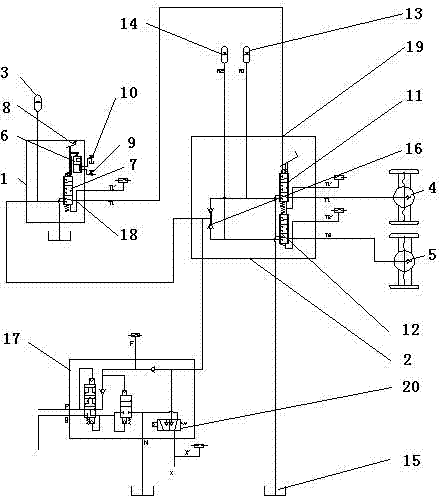

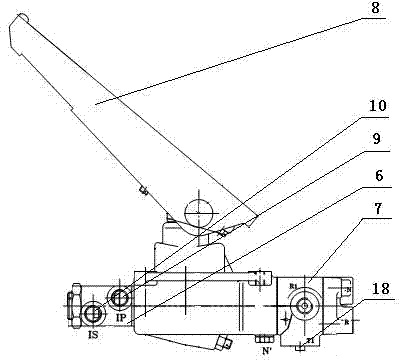

[0014] Below in conjunction with accompanying drawing, the present invention is further described:

[0015] As shown in the accompanying drawings, a hydraulic braking system for container reach stackers is provided with a car body, and the car body is provided with a left foot pedal valve 1, a right foot pedal valve 2, a liquid filling valve 17, an accumulator 3, The front axle brake 4 and the rear axle brake 5 are characterized in that the right pedal valve 2 is formed by connecting the front axle brake oil circuit and the rear axle brake oil circuit in parallel, and the front axle brake oil circuit and the rear axle brake oil circuit are connected in parallel. Pedal valve brake spools 11 and 12 are respectively arranged on the road, and the oil outlet of one brake spool 11 is connected with the front axle brake 4, and the oil outlet of the other brake spool 12 is connected with the rear axle brake 5. The oil inlets of the two spools are respectively provided with accumulator...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com