Three-dimensional vector thrusting device for submersible

A three-dimensional vector, propulsion device technology, applied in underwater ships, transportation and packaging, special-purpose ships, etc., can solve problems such as high cost and complex structure, and achieve the effects of light weight, stable operation and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

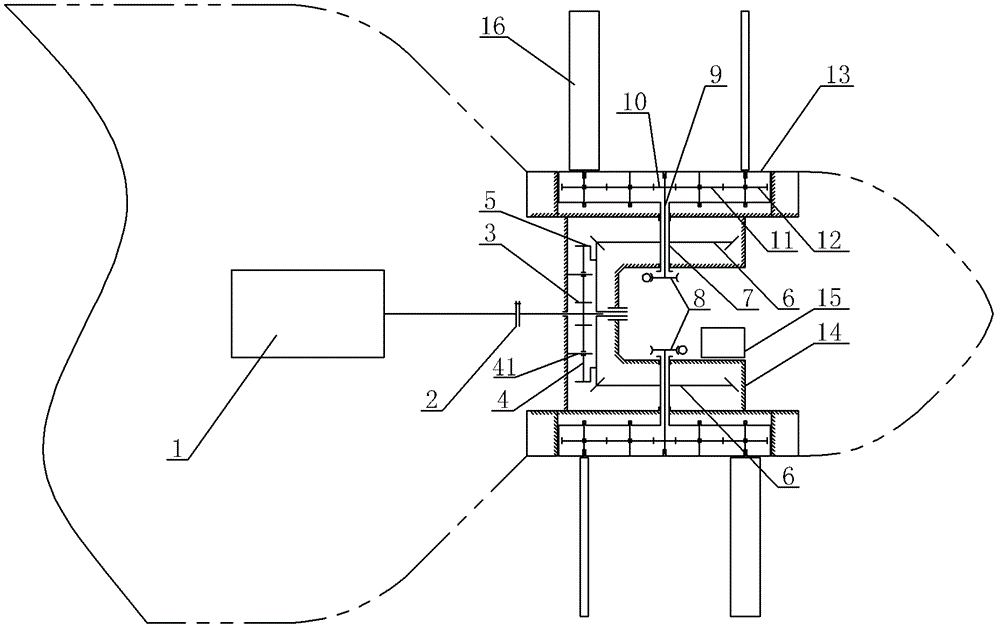

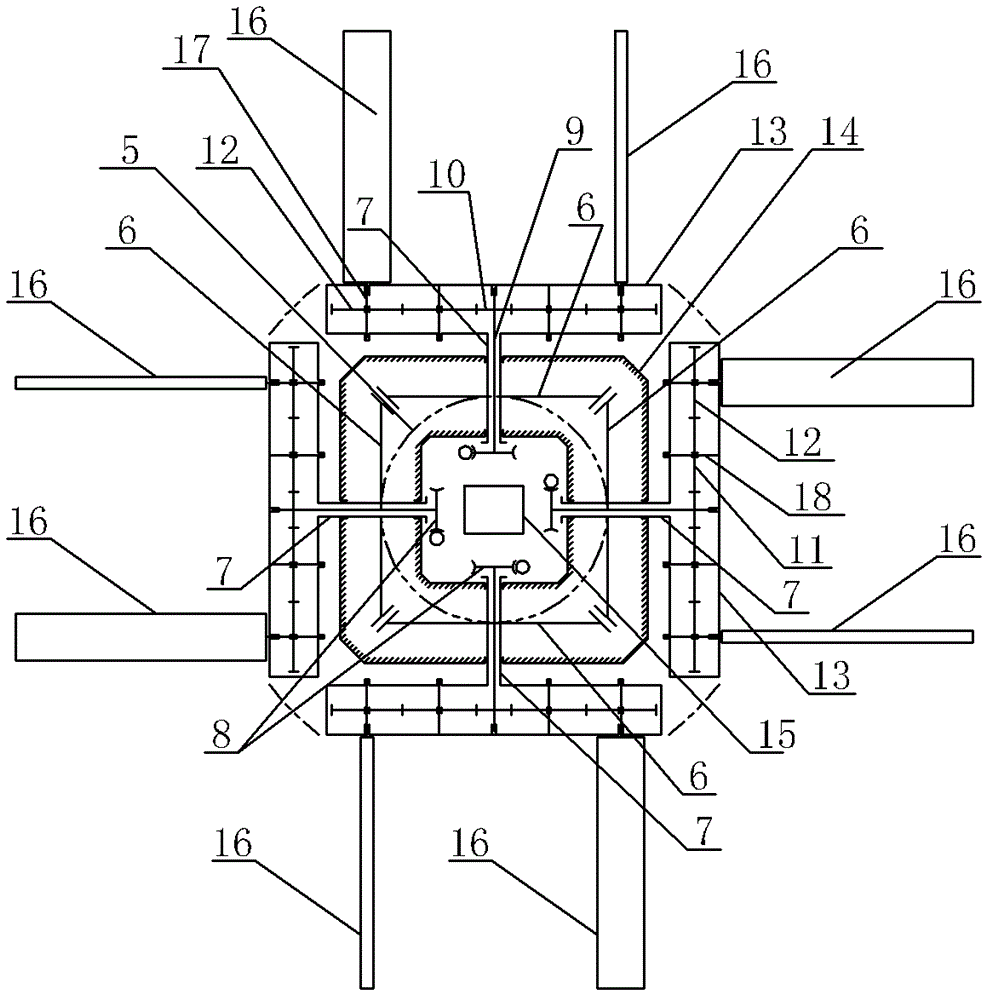

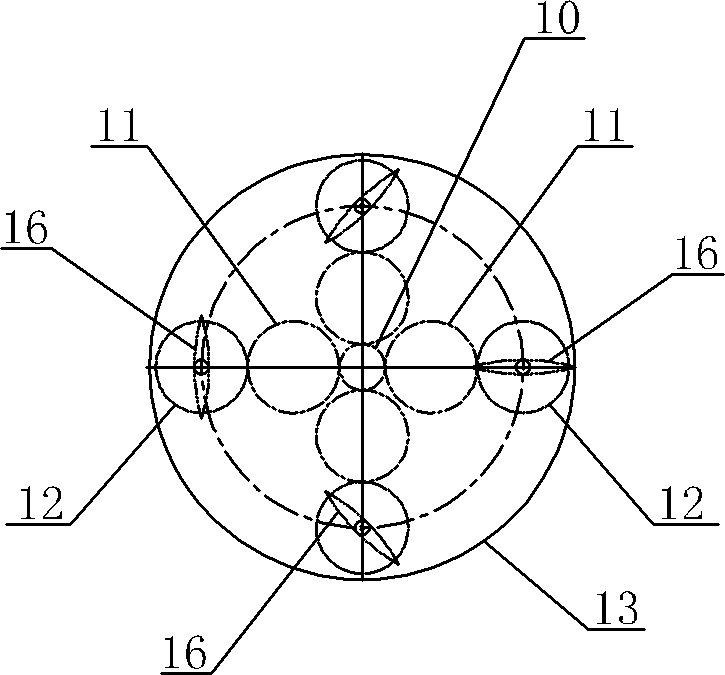

[0027] Embodiment one: if Figure 1-3 As shown, the three-dimensional vector propulsion device for the submersible of the present embodiment includes a prime mover 1, a reduction transmission mechanism, four sets of thrust mechanisms, a column base (gear box) 14, the gear box 14 is a square column, and the cross section is back-shaped. The inner ring is called the inner wall, and the outer ring is called the outer wall. The four groups of thrust mechanisms have the same structure and are symmetrically arranged around the outer wall of the gear box 14 . Each set of thrust mechanisms includes a rotating disk main gear (transmission bevel gear) 6, a rotating disk main shaft 7, a thrust direction controller 8, a transmission shaft 9, a central gear 10, a bridge gear 11, a paddle gear 12, a rotating disk 13, and a paddle Blade 16, paddle shaft 17, bridge gear shaft 18. The reduction transmission mechanism includes a shaft coupling 2, a driving gear 3, a planetary gear 4, an inner...

Embodiment 2

[0032] Embodiment two: see Figure 8 , the prime mover 1 of this embodiment is linked with the driving gear 3 in the gearbox 14 through the coupling 2, the driving gear 3 is meshed with the driven gear 4, and the driven gear 4 is linked with the bevel gear 5, so that the driven gear 4 can drive the bevel gear 5 to rotate; and the bevel gear 5 is meshed with the four rotating disk main gears 6 around, so that the bevel gear 5 can simultaneously drive the four rotating disk main gears 6 to rotate. The other content of this embodiment is the same as that of Embodiment 1, please refer to Embodiment 1.

Embodiment 3

[0033] Embodiment three: see Figure 9 , 10 , the present embodiment adopts a single prime mover drive mode, that is, each prime mover drives a group of thrust mechanisms. The prime mover 1 adopts a direct-drive motor, which is installed in the gear box 14, and its output shaft directly drives the rotating disk main shaft 7, thereby eliminating the reduction transmission mechanism and further simplifying the structure of the propulsion device. Since the rotational speed of each thruster rotating disk 13 can be adjusted arbitrarily, this technical solution can make the change of the thrust magnitude and direction of the three-dimensional vector propulsion device more flexible. For other content of this embodiment, refer to Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com