Low-loss high-dielectric adjustable titanic acid strontium barium substrate ceramic material and preparation method thereof

A barium strontium titanate and dielectric technology, which is applied in the field of electronic materials and devices, can solve the problems of no patents and undiscovered BST dielectric properties, and achieve the effects of low cost, no toxic side effects, and excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

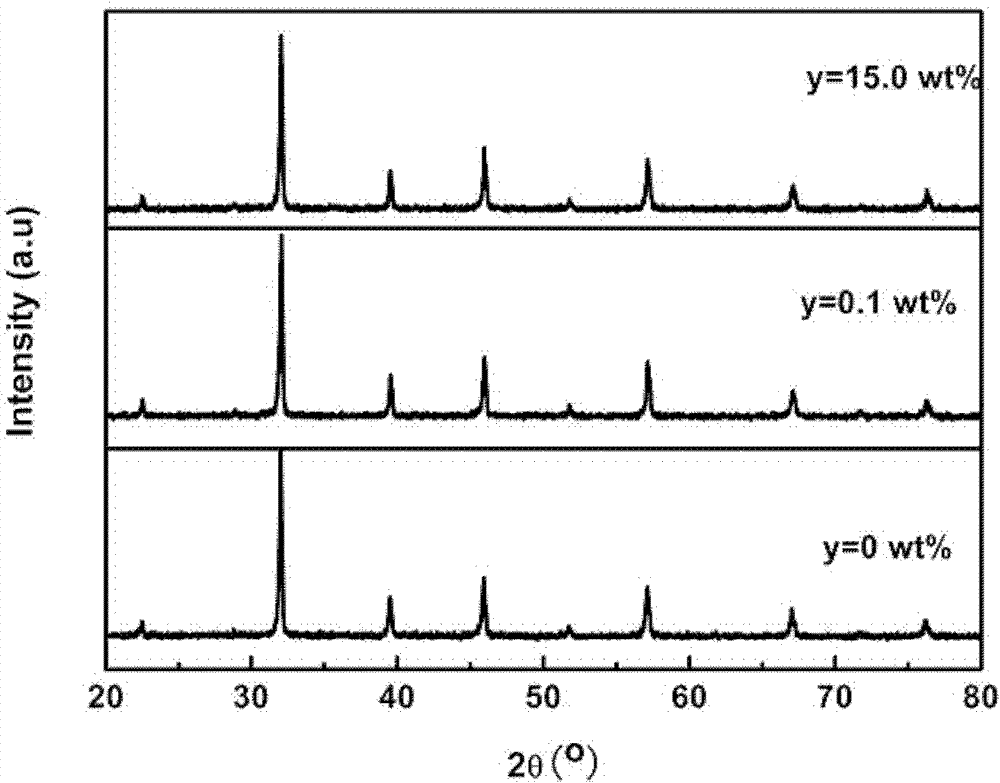

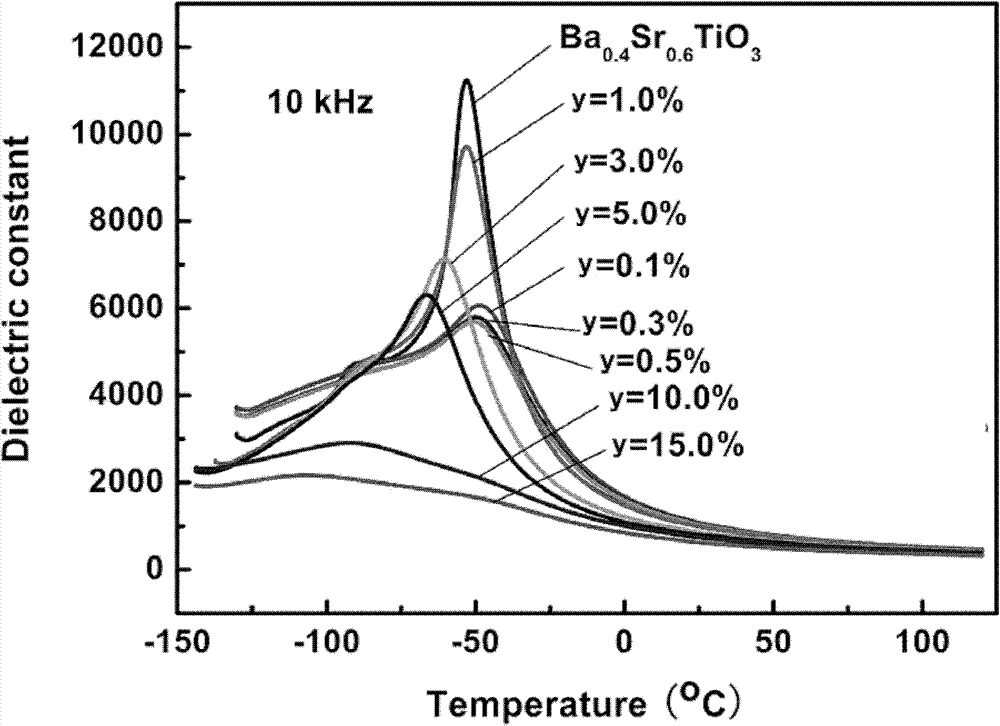

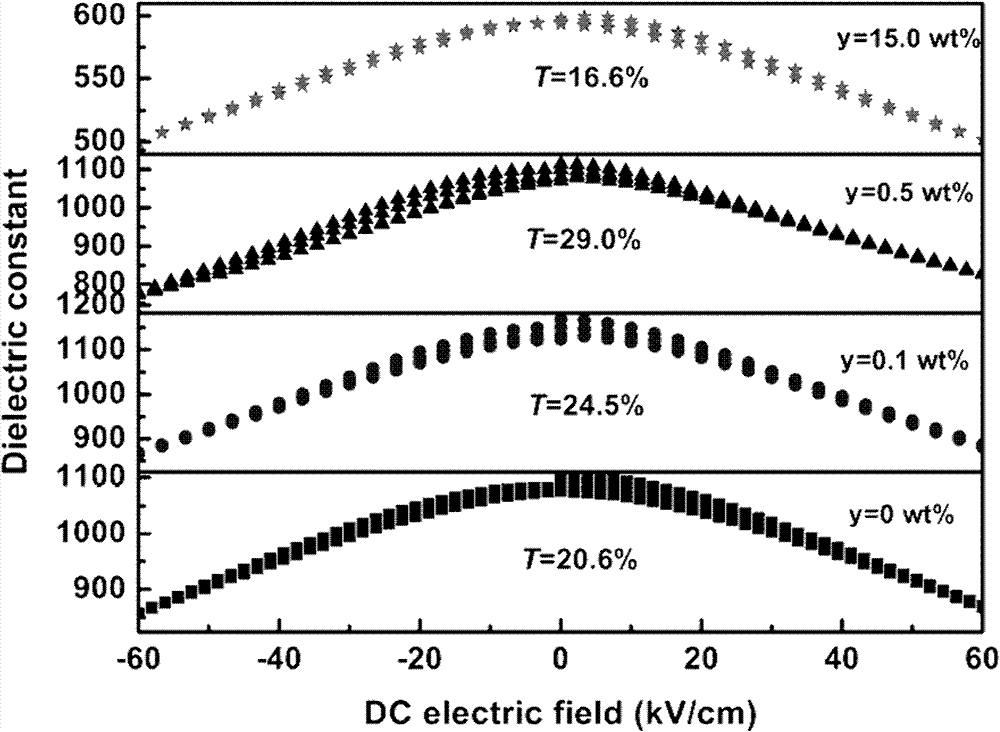

[0043] Strontium barium titanate-based microwave ceramic material with tunable dielectric (1-y)Ba 0.4 Sr 0.6 TiO 3 - the preparation of yFe, wherein (1-y) Ba 0.4 Sr 0.6 TiO 3 The composition ratio of -yFe material is shown in Table 1.

[0044] Its preparation method specifically comprises the following steps:

[0045] (1) According to Ba 0.4 Sr 0.6 TiO 3 The stoichiometric ratio, weigh 28.015g BaTiO 3 and 33.066 g SrTiO 3 The powder is placed in a nylon ball mill jar, and zirconia balls and absolute ethanol or deionized water are added, and ball milled for 24 hours (during ball milling, the mass ratio of the added zirconia balls to the ball grinding material is 1.5:1; the added absolute ethanol Or the mass ratio of deionized water to ball milling material is 3.0:1), after discharging and drying, pre-calcine at 1200°C for 4 hours, and obtain Ba 0.4 Sr 0.6 TiO 3 The powder is ready for use.

[0046] Take the above-mentioned synthesized Ba respectively according to ...

Embodiment 2

[0054] Strontium barium titanate-based microwave ceramic material with tunable dielectric (1-y)Ba 0.4 Sr 0.6 TiO 3 - the preparation of yFe, wherein (1-y) Ba 0.4 Sr 0.6 TiO 3 The compositional distribution of -yFe material is shown in Table 3.

[0055] Its preparation method specifically comprises the following steps:

[0056] (1) According to Ba 0.4 Sr 0.6 TiO 3 The stoichiometric ratio, weigh 28.015g BaTiO 3 and 33.066 g SrTiO 3 The powder is placed in a nylon ball mill jar, and zirconia balls and absolute ethanol or deionized water are added, and ball milled for 20 hours (during ball milling, the mass ratio of the added zirconia balls to the ball grinding material is 1.2:1; the added absolute ethanol Or the mass ratio of deionized water to ball milling material is 1.5:1), after discharging and drying, it is pre-fired at 1100°C for 4 hours, and after grinding, Ba 0.4 Sr 0.6 TiO 3 The powder is ready for use.

[0057] Take the above-mentioned synthesized Ba resp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com