Underwater optical cable connector

An underwater optical cable and connector technology, which is applied to the coupling of optical waveguides and other directions, can solve the problems of inapplicability, cumbersome structure, and cannot be easily opened, etc., and achieves the effects of simple structure, convenient disassembly, and stable and reliable performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

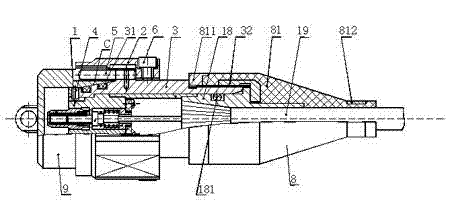

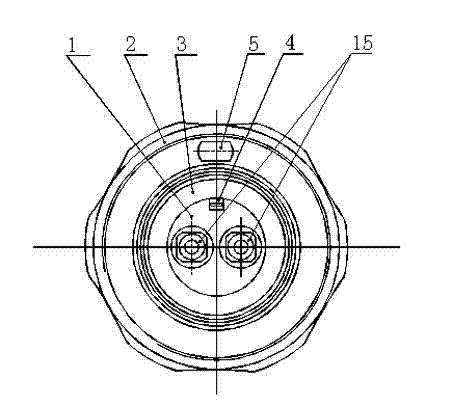

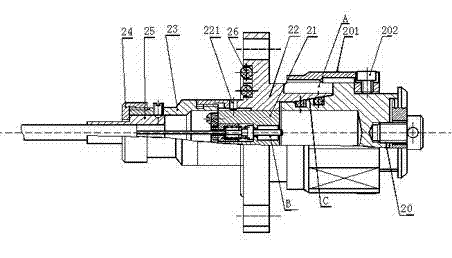

[0022] The overall structure of the plug is as follows figure 1 , figure 2 shown. figure 1 , figure 2 Among them, 1 is the pre-assembled inner core body; 2 is the connecting nut; 3 is the plug shell, the plug shell 3 is provided with an outer cone structure C, and the outer cone structure is provided with two "O"-shaped sealing rings 31 ; 4, 5 are positioning pins; 6 is a locking screw; 8 is the tail assembly of the plug;

[0023] For the convenience and ease of the assembly and processing process, we make the inner core body 1 of the plug (see Fig. 5(a)) into a whole; when the connector plug is assembled, it is first assembled. In this embodiment, it mainly consists of a substrate 10, a ceramic ferrule 11, a spring 12, a spring seat 13, a ceramic jack 14, an outer sleeve 15 of the jack, a rear pressure plate 16, an inner core sleeve 17,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com