Bionic texture membrane

A biomimetic muscle and film treatment technology, applied in the field of biomimetic texture film, can solve the problems of waste time and force, inability to express dermis skin texture, etc., and achieve the effects of thin thickness, low resilience, and simple and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

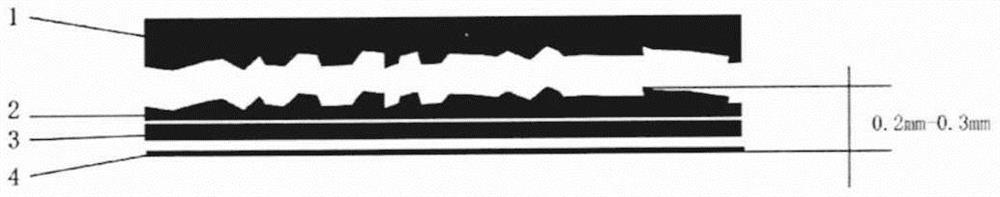

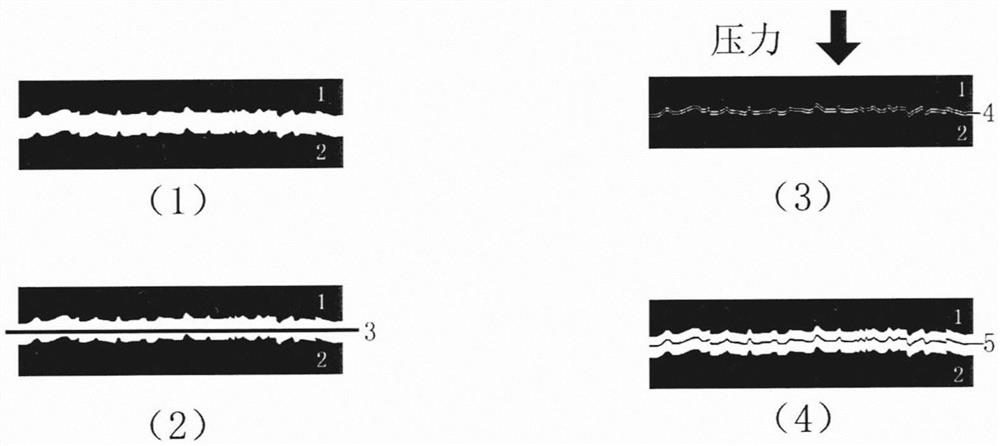

[0022] The specific implementation process of the bionic texture film is: texture collection; making texture mold paper; making texture layer; making functional layer.

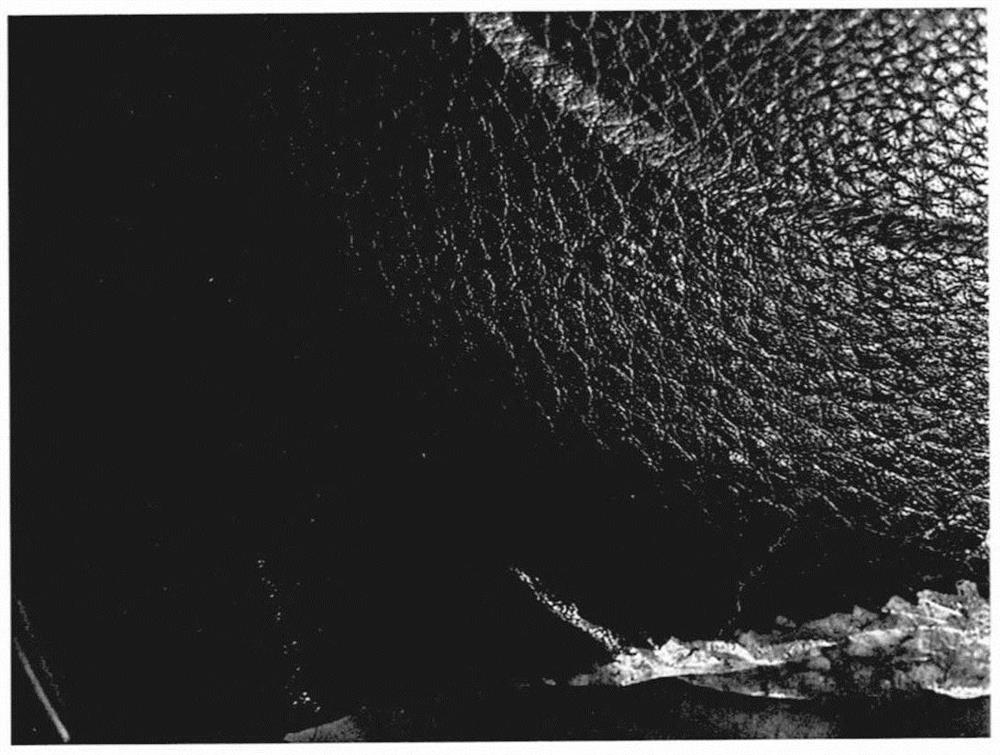

[0023] 1 Texture collection: Texture collection includes two types: natural texture and digital texture.

[0024] Natural texture acquisition: use laser 3D scanner to directly digitize the surface texture of natural products.

[0025] Digital Texture Design: It is a digital texture created and designed by designers using 3D software.

[0026] 2. Making texture mold paper: Texture mold paper is the process of directly copying natural texture or digital texture onto texture mold paper. The specific implementation method is as follows: the texture concave-convex metal mold is made. Using the collected texture data, use a mirror spark machine to make two concave and convex metal molds. (For the same texture, make a concave mold and a convex mold) Then place the coated paper with a thickness of 2 mm in the middl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com