Method for producing dual-interface card

A dual-interface smart card, dual-interface technology, applied in the field of information, can solve the problems of uneven front of the dual-interface module, affecting use, poor precise control of heating time, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention will be described in further detail below in conjunction with the accompanying drawings.

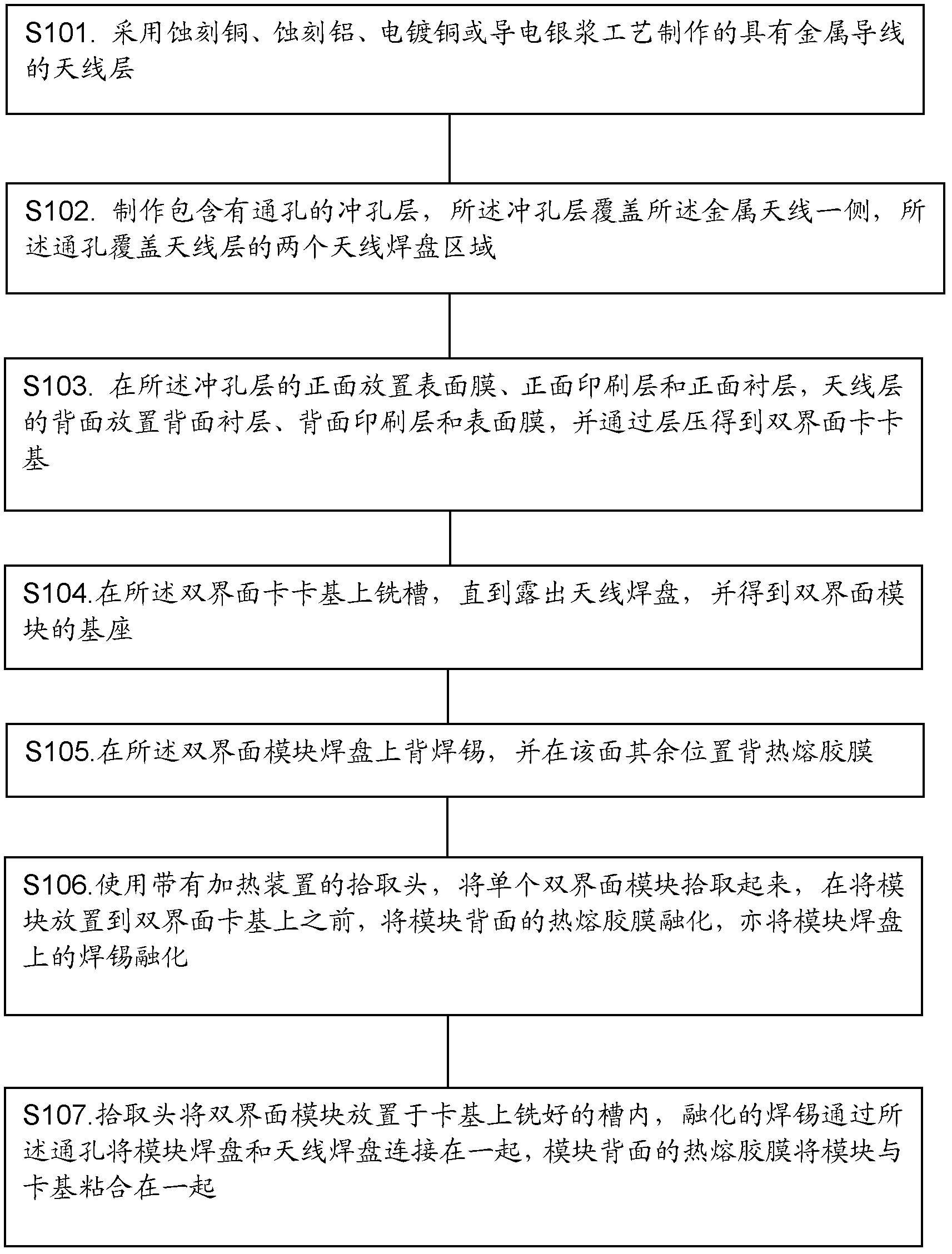

[0043] like image 3 As shown, Embodiment 1 of the present invention provides a method for producing a dual-interface card, the method comprising:

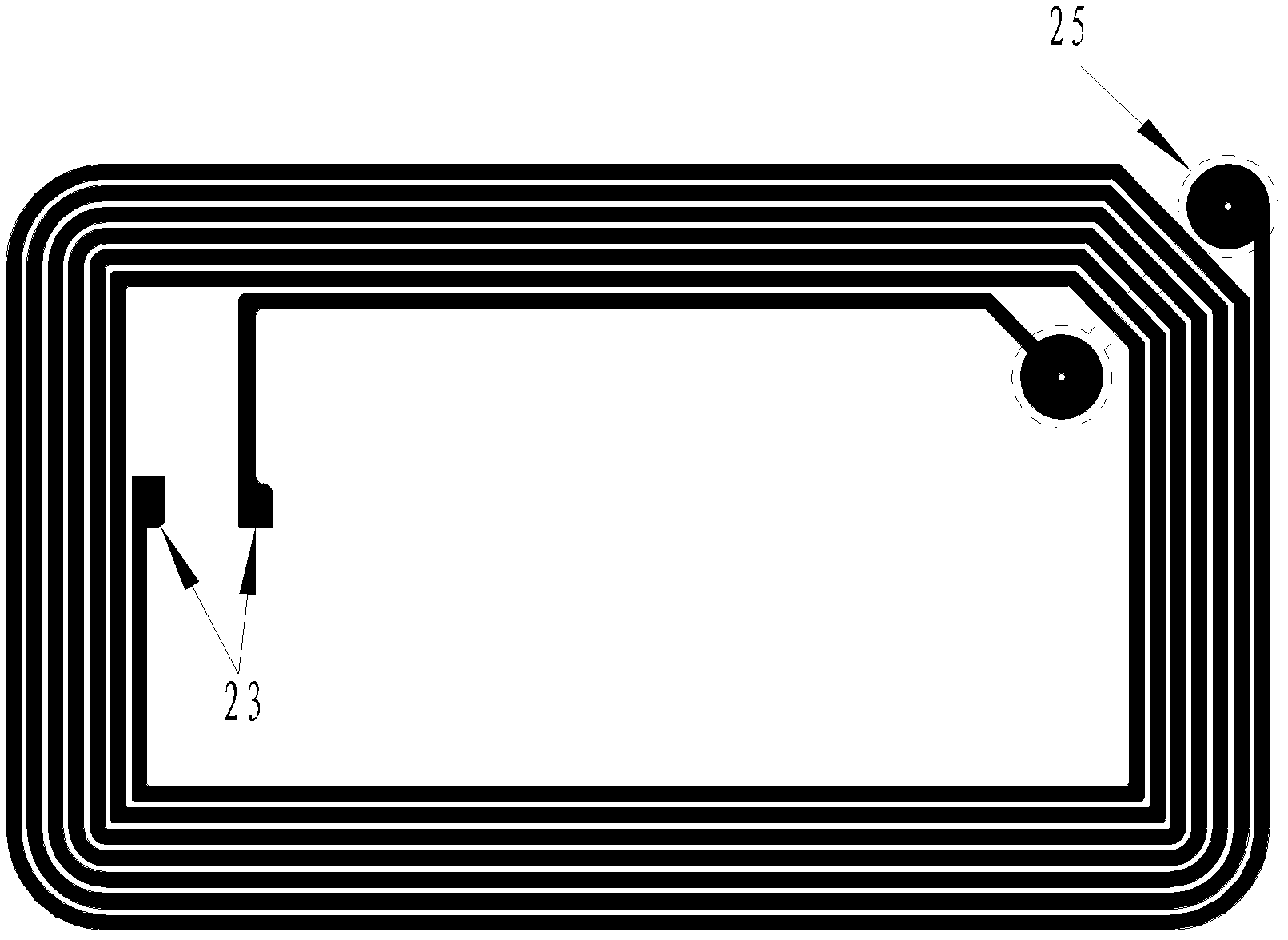

[0044] S101. The antenna layer with metal wires made by etching copper, etching aluminum, electroplating copper or conductive silver paste;

[0045] Wherein, preferably, the thickness of the metal layer of the metal antenna is less than 0.05 mm, the carrying material is polyester plastic, and the thickness is 0.02-0.20 mm;

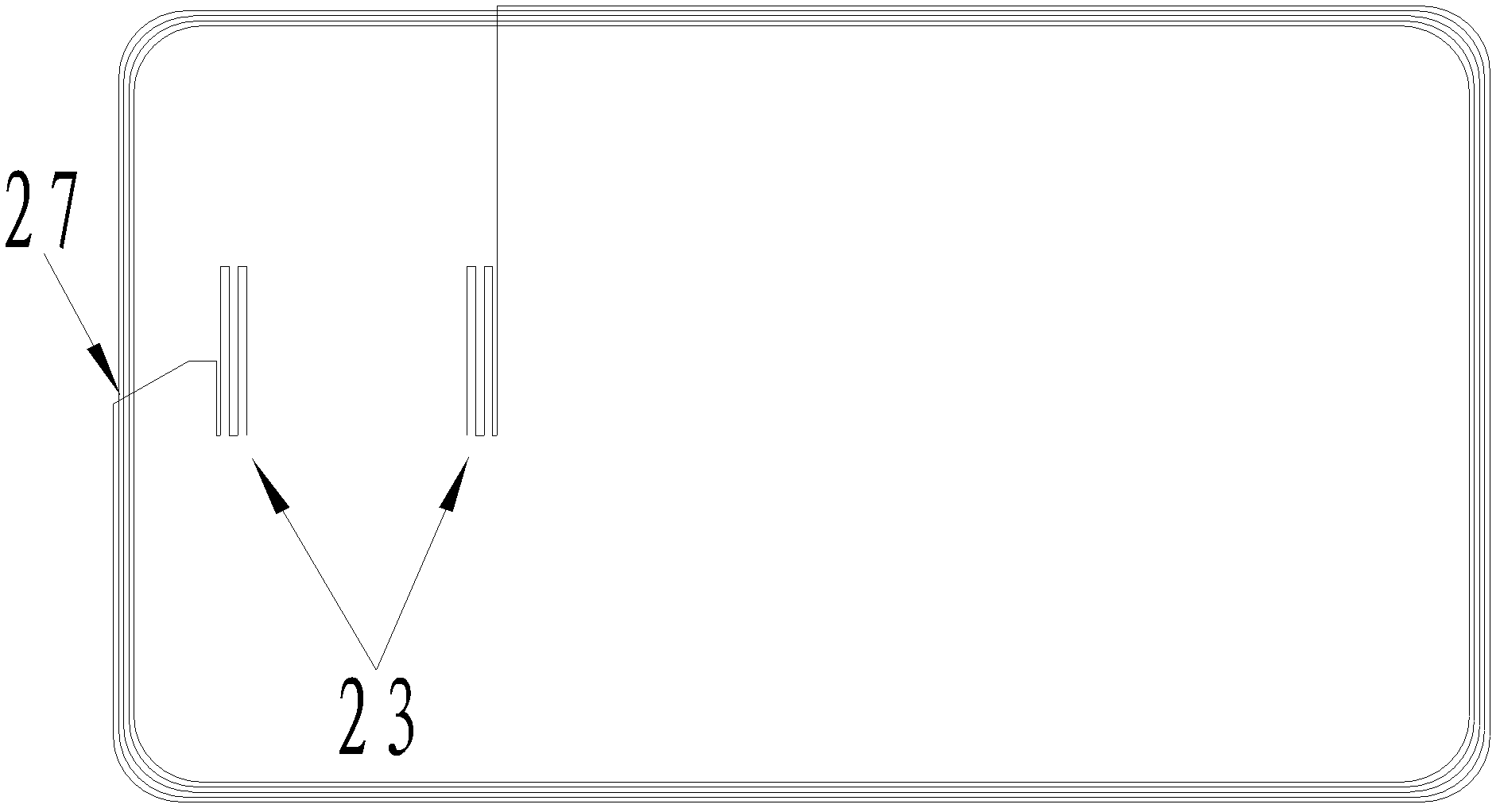

[0046] S102. Make a punching layer including a through hole, the punching layer covers one side of the metal antenna, and the through hole covers two antenna pad areas of the antenna layer;

[0047] S103. Place a front printing layer and a lining layer on the front of the punching layer, place a back printing layer and a lining layer on the back of the antenna layer, and obtain a double-int...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com