Air duct structure for cast coil and manufacturing method for air duct structure

A technology of casting coils and manufacturing methods, which is applied in coil manufacturing, transformer/inductor coil/winding/connection, transformer/inductor cooling, etc. It can solve problems such as easy to scatter, fall off, inconvenient processing, etc., and achieve convenient processing , enhanced insulation level, beautiful and neat appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described through the embodiments below in conjunction with the accompanying drawings.

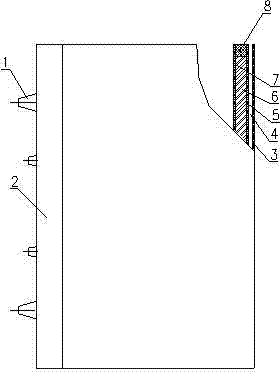

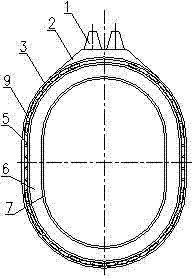

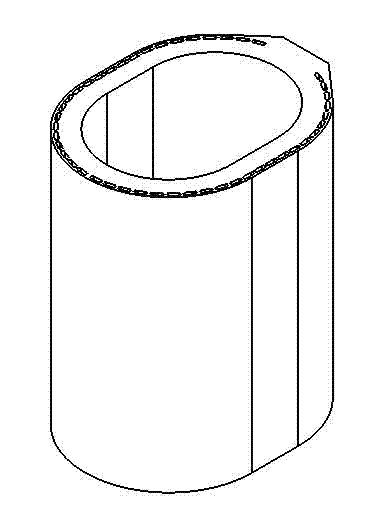

[0015] A method for manufacturing an air duct structure of a cast coil, comprising the following process steps: ① After the wire part 6 of the coil is wound, a plurality of air passage plates 9 are placed outside, and glass mesh and glass cloth are directly wound outside the air passage plates The outer mixed layer 3 is formed, and then the epoxy resin casting of the coil is performed; ② After the casting is completed, the air channel plate is pulled out, so that a cylindrical resin layer with an air channel structure will be formed outside the coil.

[0016] The cylindrical resin layer is mainly made of epoxy resin material, and mixed with a mixed layer composed of glass mesh and glass cloth tape. The stiffness of the air duct.

[0017] A more specific manufacturing method for the air guide tube structure of the casting coil:

[0018] Coils a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com