Preparation method of photo-anode of ZnS/Au/TiO2 nano composite film

A nanocomposite and photoanode technology, applied in the field of photoanode, can solve the problems of poor photocathode protection effect and low photoelectric conversion efficiency of nanomaterials, so as to improve the protection effect, reduce the recombination probability, and increase the photocurrent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

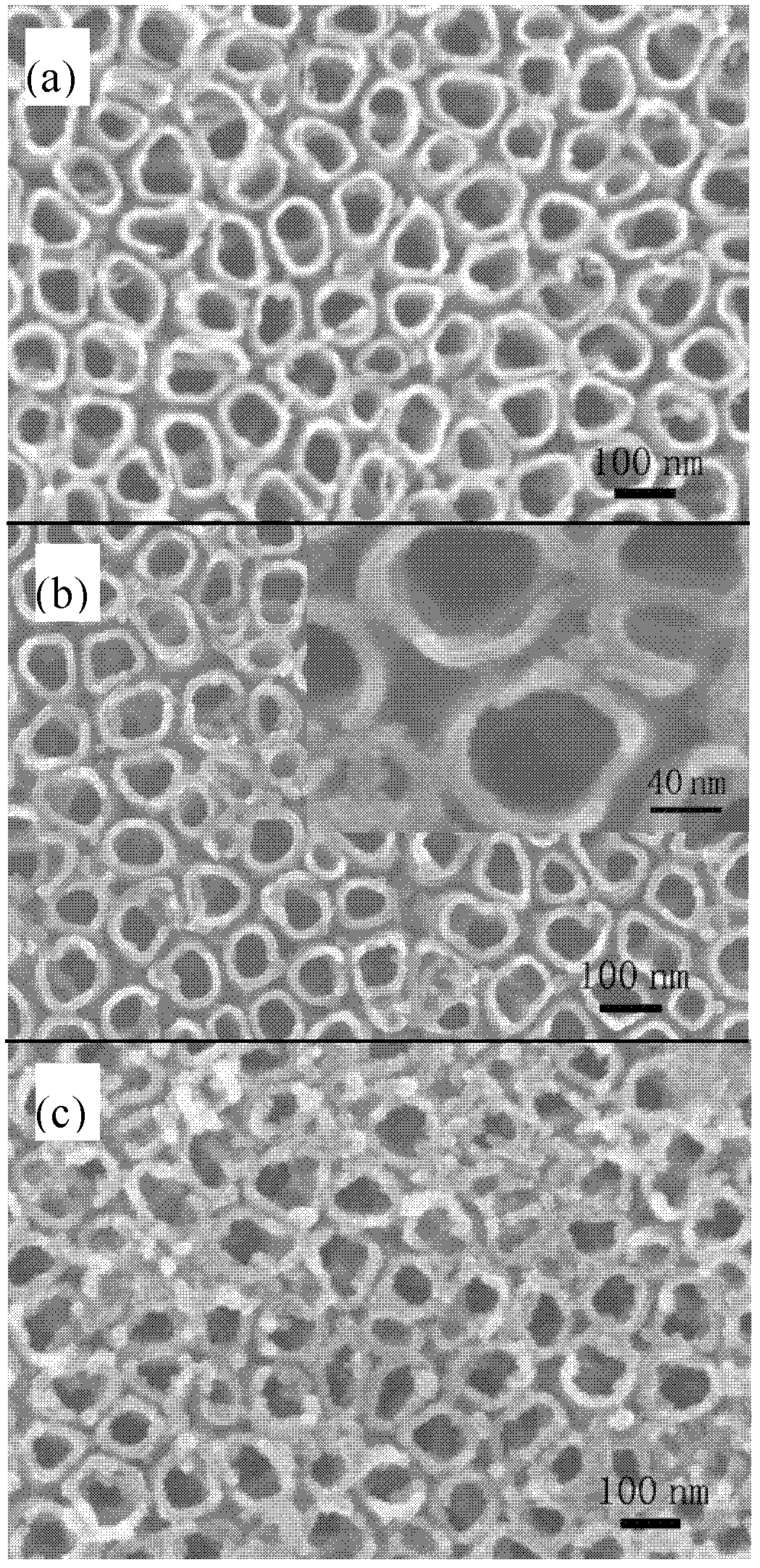

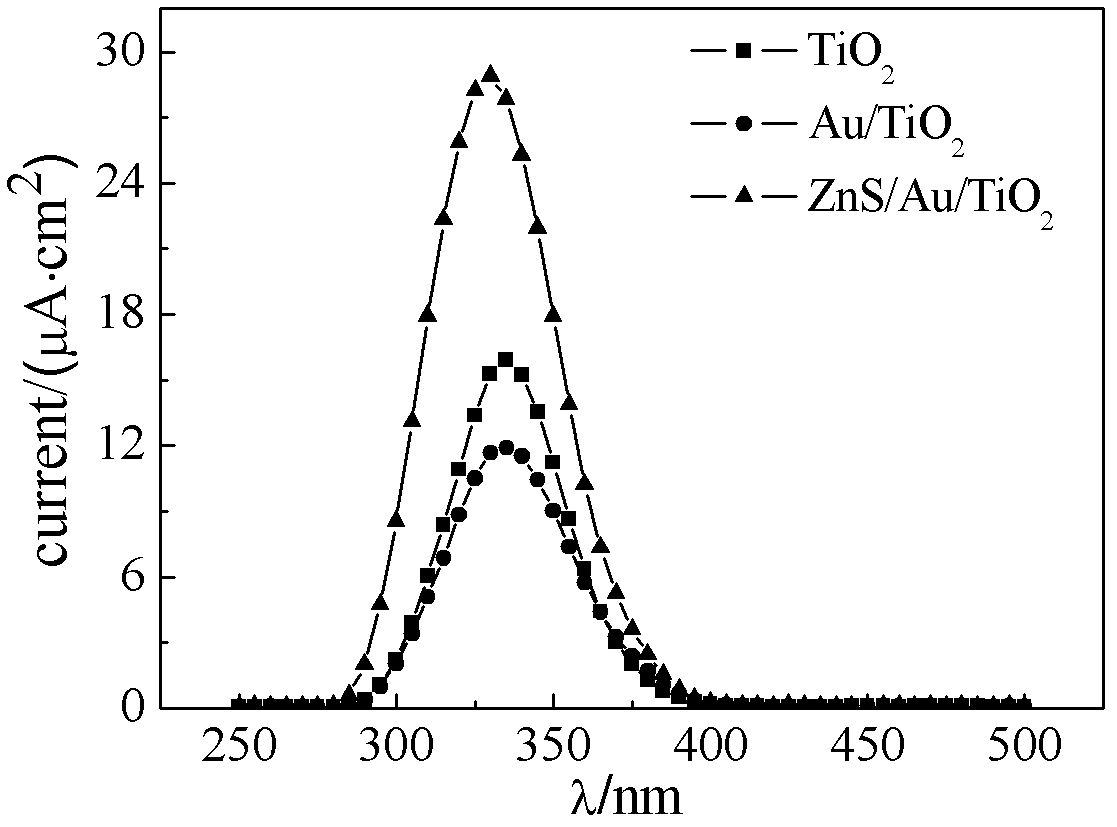

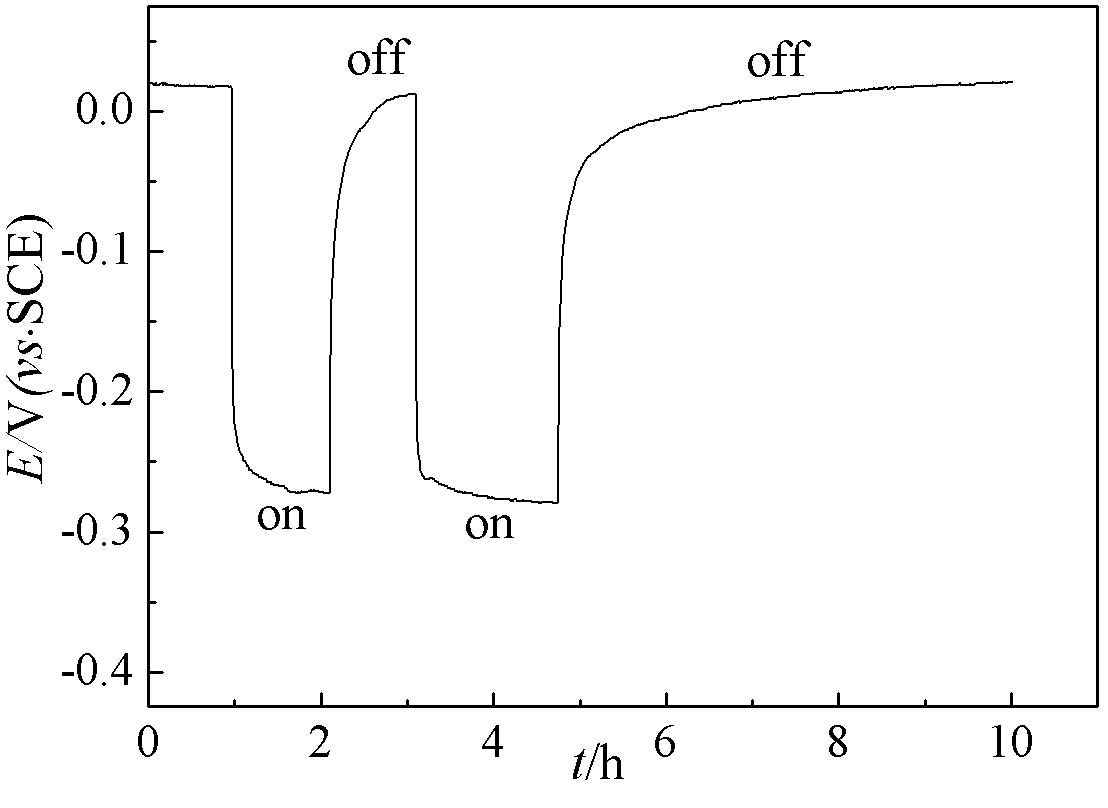

[0028] According to the above-mentioned technical scheme (concrete steps), prepare ZnS / Au / TiO 2 Nanocomposite film photoanode, and test the cathodic protection effect of this film on 403 stainless steel.

[0029] First, take a pure titanium foil sample with a thickness of 0.1 mm, a length of 2.0 cm, and a width of 1.0 cm, and pass through 10% (w) HNO at room temperature 3 +1% (w) HF solution etching treatment for 1 min, followed by ultrasonic cleaning in acetone, absolute ethanol and deionized water for 30 min to complete the pretreatment of the titanium matrix sample.

[0030] TiO 2 Preparation of the nanotube array film: at room temperature, with the treated titanium foil as the anode and the platinum sheet as the cathode, apply a voltage of 20V in 0.5% (w) HF solution, and anodize the sample for 30 minutes. After the reaction, the samples were washed with deionized water, dried and placed in a muffle furnace for heat treatment at 450 °C for 2 h.

[0031] Au-modified TiO ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com