Super-doped silicon thin film solar cell and manufacturing method thereof

A technology of solar cells and manufacturing methods, applied in the field of solar cells, can solve the problems of large series resistance of photovoltaic devices, low photoelectric conversion efficiency, high light absorption rate of materials, etc., to meet the diffusion length limit, reduce sheet resistance and defect recombination, Reduce the effects of scattering and compounding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

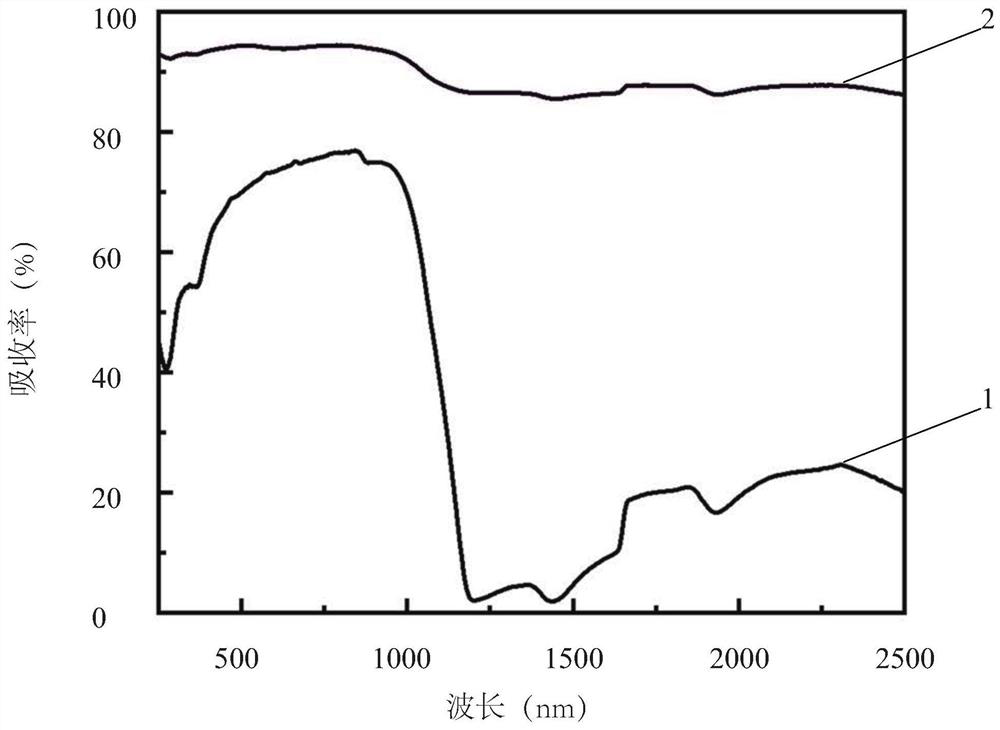

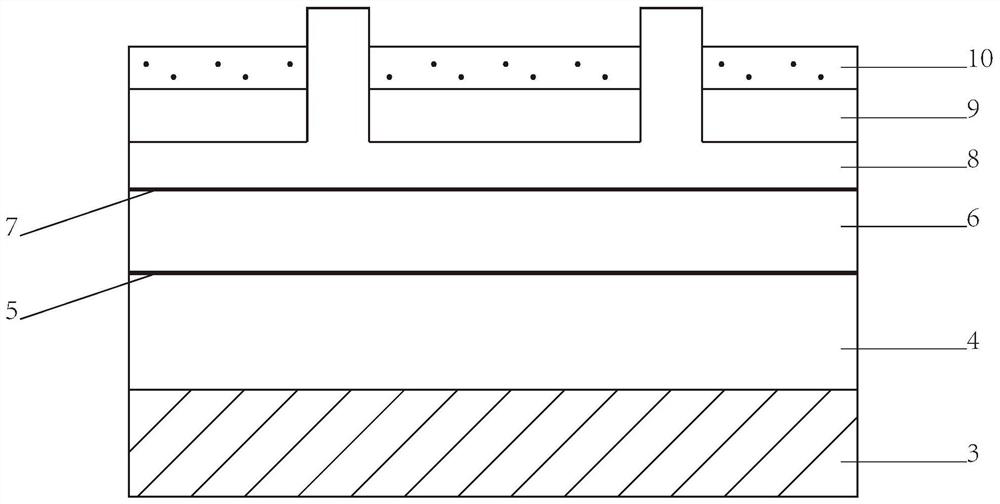

[0039] Such as figure 2 As shown, the structure of a crystalline silicon solar cell includes a P-type layer 4, a PN junction 5, an N-type layer 6, a back electrode 3 connected to the P-type layer, a light-trapping layer 7, a front electrode 8 connected to the N-type layer, and SiN x Layer 9.

[0040] The processing of crystalline silicon solar cells using the manufacturing method of the present invention is as follows.

[0041] will be like figure 1 The crystalline silicon solar cell shown as a substrate is cleaned and dried, and then an electrode mask is applied to the front electrode.

[0042] Put the crystalline silicon solar cell after the electrode mask into the vacuum chamber of the vacuum coating machine.

[0043] Vacuumize the vacuum chamber, and at the same time use graphite crucible to hold silicon particles with a purity greater than 99.9999% into the electron beam coating device, and use a tungsten boat to hold 0.001mol~0.01mol of transition metal element powde...

example 2

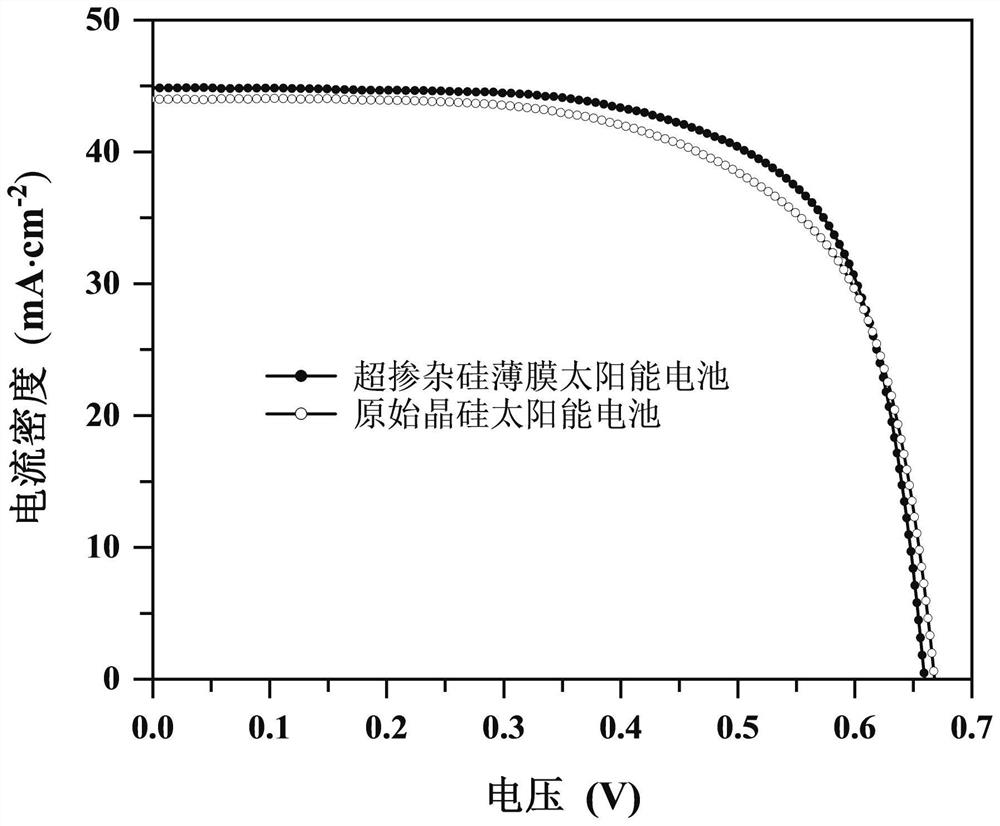

[0048] Using crystalline silicon solar cells as substrates, super-doped silicon thin-film solar cells manufactured according to the manufacturing method of the present invention. Under the same conditions, test the volt-ampere characteristics (that is, the relationship between current density and voltage) of pristine crystalline silicon solar cells and hyper-doped silicon thin-film solar cells, where the current density is in mA cm -2 , the voltage is in V, and the test results are as follows image 3 As shown, according to the test results, it can be seen that the current density (also can be said to be the absorption rate or photoelectric responsivity to light) of the super-doped silicon thin film solar cell is higher than that of the original crystalline silicon solar cell at a voltage of 0-0.6V. significantly improved.

[0049] In summary, the beneficial effects of the present invention may include:

[0050] (1) It can improve the energy utilization of the light (light w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com