Microchannel positioning structure of silicon photocell and positioning method based on same

A technology of silicon photocell and positioning structure, applied in the direction of using optical devices, measuring devices, instruments, etc., can solve the problems of high demand for image processing hardware and high cost of CCD

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

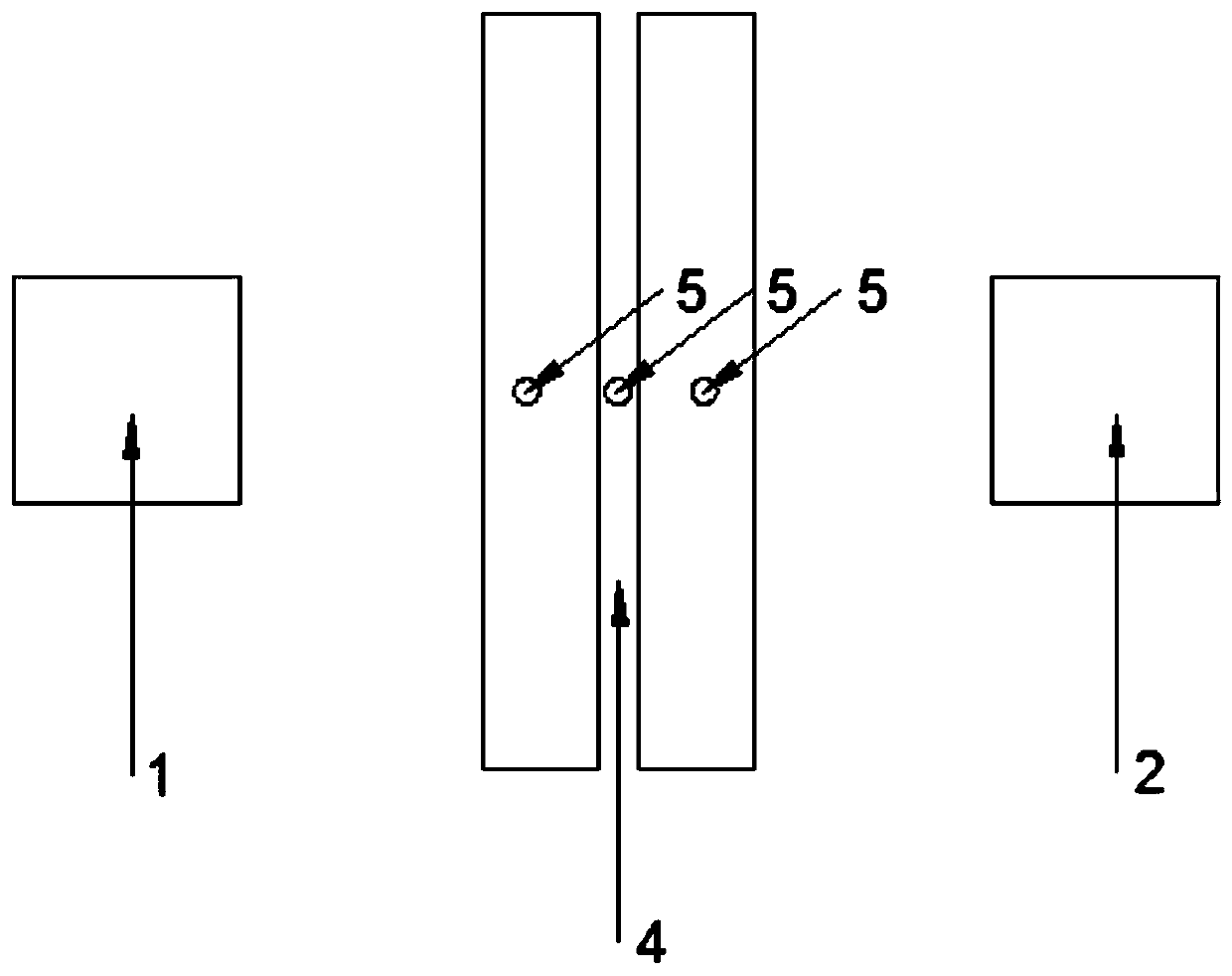

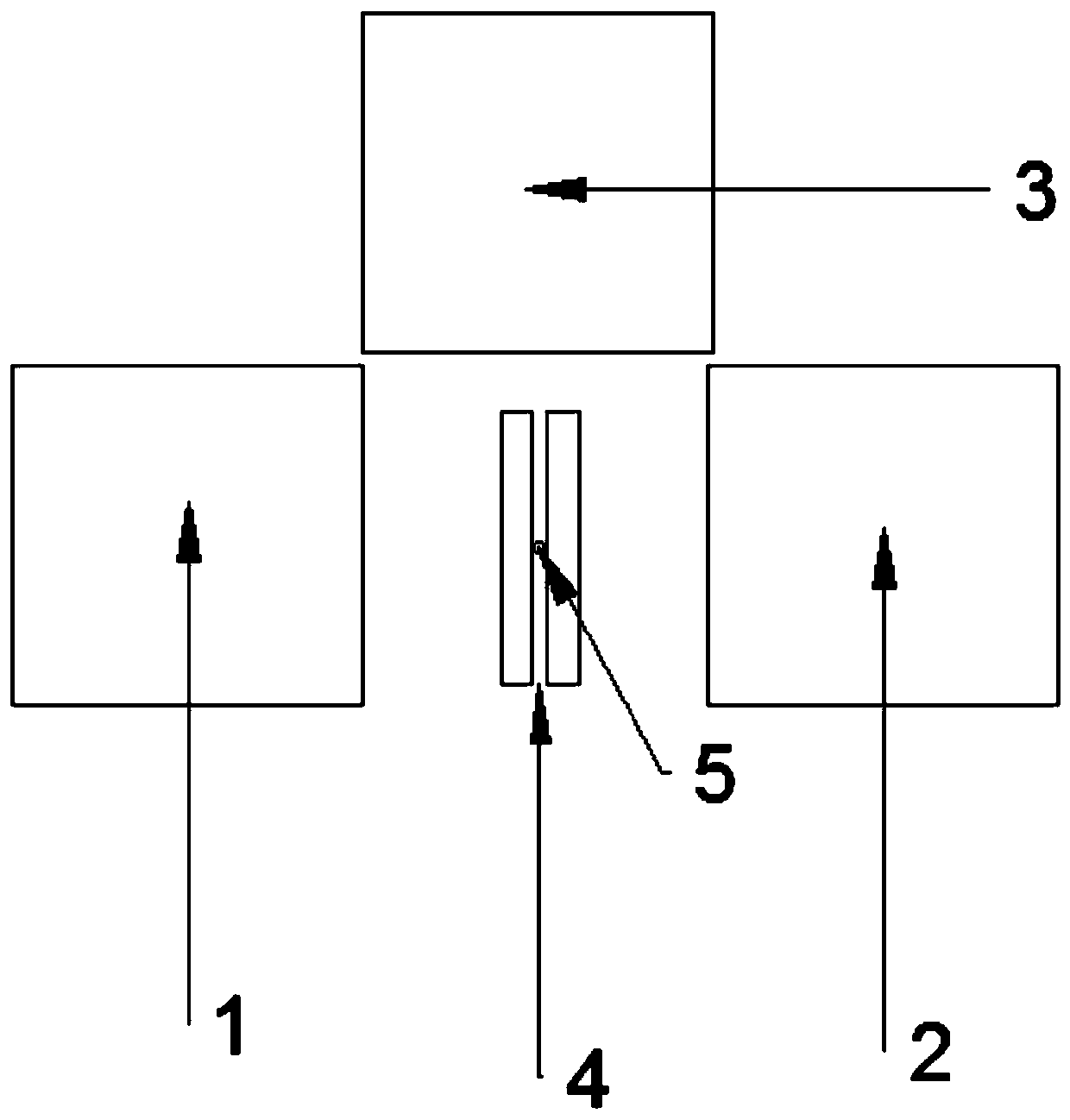

[0032] see Figure 1-9 , a microchannel positioning structure of a silicon photovoltaic cell, including a microchannel 4 and a light source 5, and also includes a silicon photovoltaic cell 6 and a mounting block 9, the bottom surface of the silicon photovoltaic cell 6 is provided with pins 7, and the silicon photovoltaic cell 6 includes a No. 1 silicon photovoltaic cell 1, No. 2 silicon photovoltaic cell 2 and No. 3 silicon photovoltaic cell 3, the installation block 9 is provided with a T-shaped installation groove 8, and No. 1 silicon photovoltaic cell 1, No. 2 silicon photovoltaic cell 2 and No. No. 1 silicon photovoltaic cell 3 is located on the perpendicular bisector of the line connecting No. 1 silicon photovoltaic cell 1 and No. 2 silicon photovoltaic cell 2. A microchannel 4 is arranged on the side of the line connecting No. 1 silicon photovoltaic cell 1 and No. 2 silicon photovoltaic cell 2, and the microchannel 4 is vertical On the plane where No. 1 silicon photovolt...

Embodiment 2

[0038] A method for positioning a microchannel positioning structure based on silicon photovoltaic cells, the steps are as follows:

[0039] 1) Install No.1 silicon photocell 1, No.2 silicon photocell 2 and No. On the vertical bisector of the photovoltaic cell 2, a microchannel 4 is arranged between the No. 1 silicon photovoltaic cell 1 and the No. One side of photocell 3;

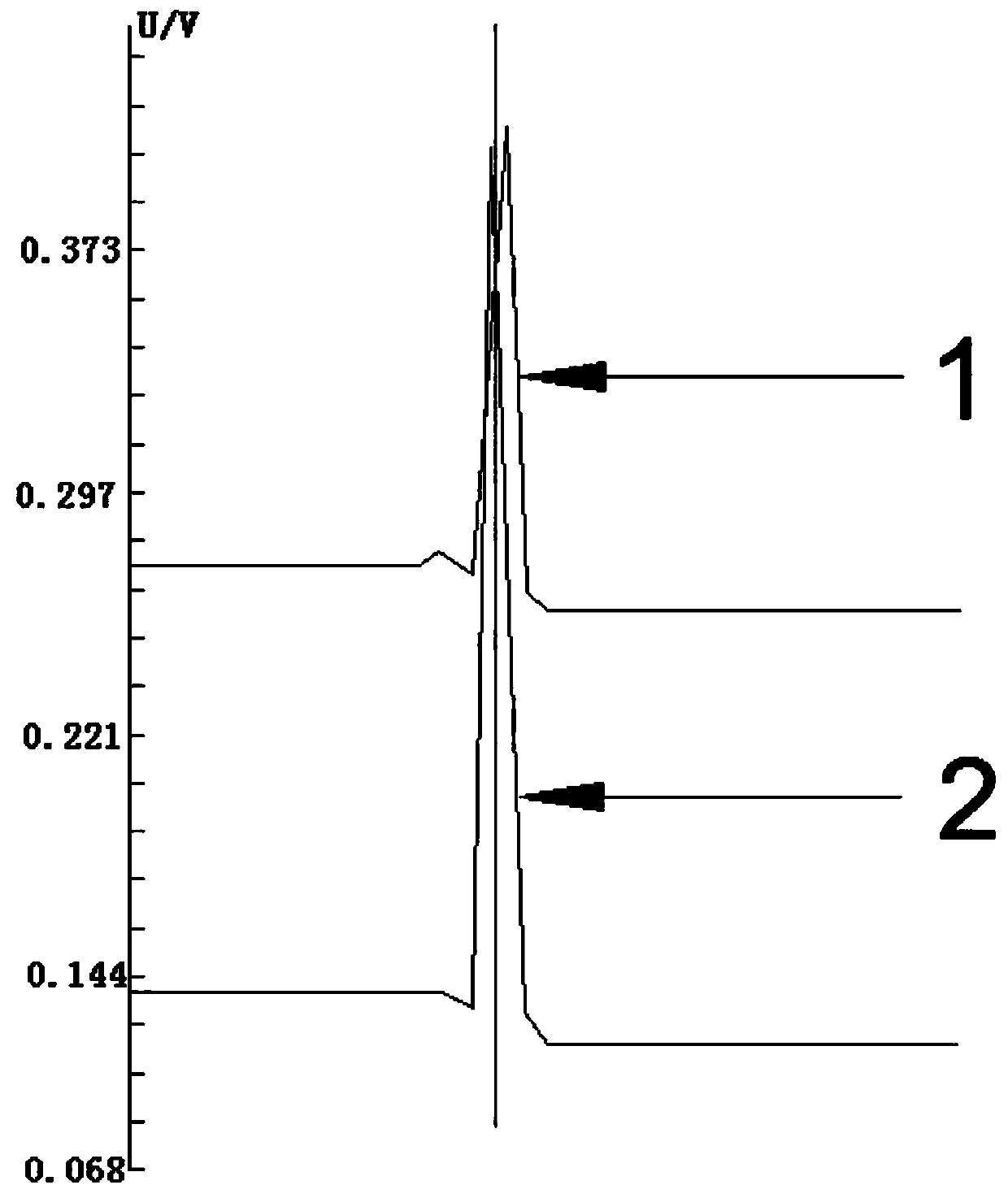

[0040] 2) The light source 5 emits light, moves the microchannel 4 vertically along the No. 1 silicon photocell 1 to the No. 2 silicon photocell 2, and detects the feedback of the photoelectric effect of the No. 1 silicon photocell 1 and No. 2 silicon photocell 2;

[0041] 3) When the light source 5 emits light through the microchannel 4, the microchannel 4 is rotated and offset along the horizontal angle. After the microchannel 4 is offset, the No. 1 silicon photovoltaic cell 1, the No. 2 silicon photovoltaic cell 2 and the Feedback of the photoelectric effect of No. 3 silicon photovoltaic cell 3;

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com