High-voltage vacuum circuit breaker

A vacuum circuit breaker, high-voltage technology, applied in the direction of high-voltage air circuit breakers, high-voltage/high-current switches, circuits, etc., can solve the problem that non-professionals cannot debug, overhaul, drive system power dissipation is too large, and drive system design Complications and other issues, to achieve the effect of improving practical value, good anti-aging performance, and realizing waste utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

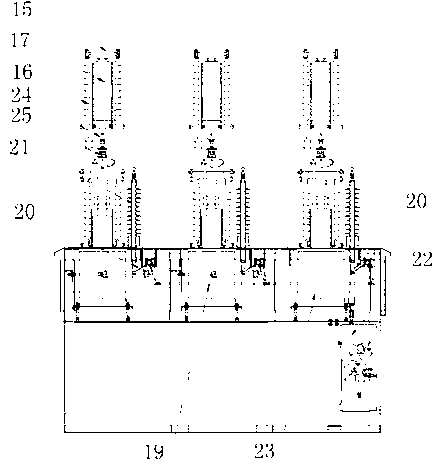

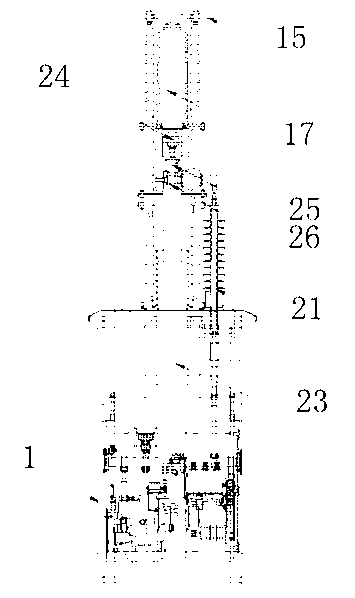

[0042] like figure 1 and figure 2 As shown, the high-voltage vacuum circuit breaker mainly includes the operating mechanism, the current transformer system installed above the operating mechanism, the vacuum interrupter unit located above the current transformer system, and the vacuum interrupter unit and the current transformer. The supporting mechanism used to support the vacuum interrupter unit between the vacuum interrupter systems, and the transmission mechanism connecting the operating mechanism and the current transformer system.

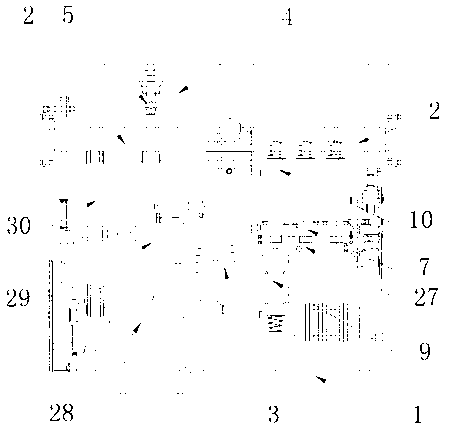

[0043] In the above structure, the operating mechanism such as image 3 As shown, its overall structure includes a mechanism box 1, a main shaft 2 installed inside the mechanism box 1, a kneeling buffer limit device, a closing system, an opening system, a power unit and an energy storage spring 3.

[0044] Among them, such as Figure 4 , Figure 5 As shown, the kneeling buffer limit device includes a buffer 5 installed on the main shaft 2,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com