Wishbone shaped bell-less blast furnace distributor

A technology of distributor and bellless, applied in blast furnace, blast furnace details, blast furnace parts, etc., can solve the problems of difficult synchronization of three hydraulic cylinders, high cost of spare parts and maintenance, irreparable damage to the distributor, etc. To achieve the effect of controlling the tilting amount of the support ring, long service life and short transmission chain

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

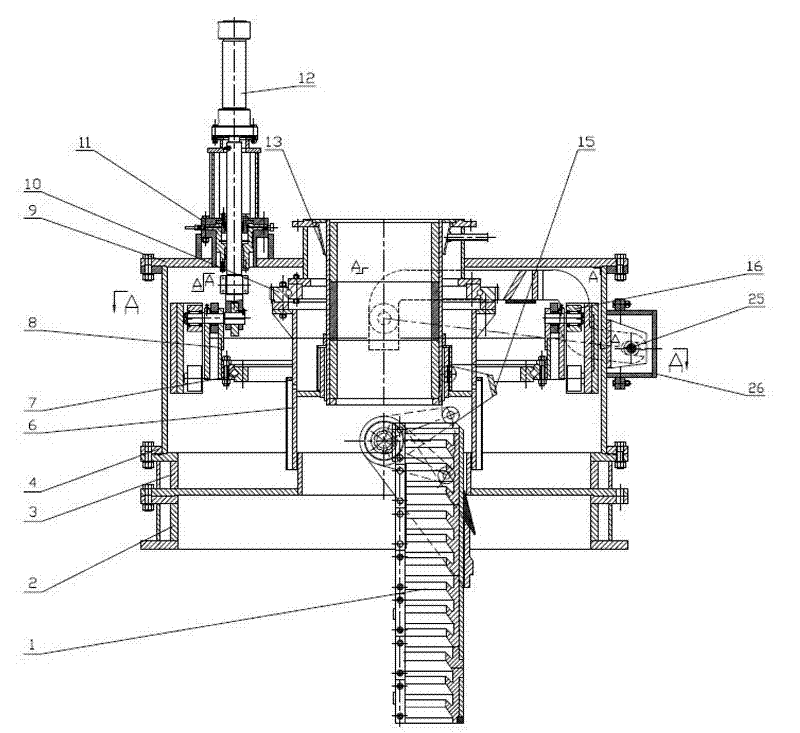

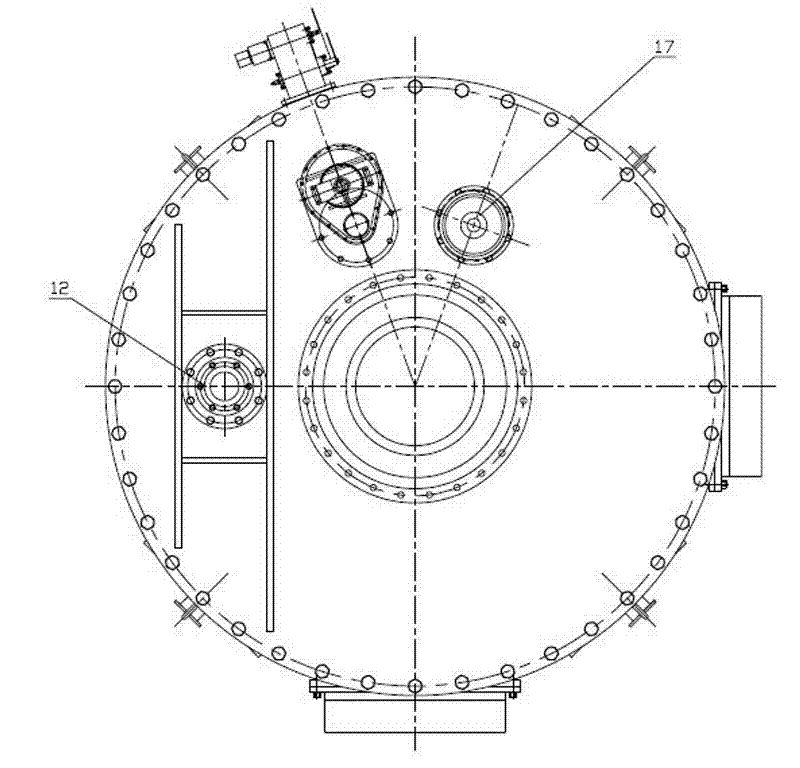

[0050] Embodiment 1: as Figures 1 to 8 A yoke-type bellless distributor for a blast furnace is shown, including a distributor box 4, a top cover 9, a water cooling plate 3, an upper slewing bearing 10, a rotating sleeve 6, a support ring 8, a lower slewing bearing 7, ear Shaft 19, trunnion crank 23, chute bracket 20, chute 1, throat 13 and horizontal transmission device 17 for controlling the β angle of the chute; Rotating sleeve, the center line of the rotating sleeve coincides with the center line of the blast furnace; the lower part of the support ring 8 is fixedly connected with the outer ring of the lower slewing bearing; the lower part of the rotating sleeve is symmetrically provided with trunnion sleeves. Two trunnions are worn, and the two trunnions are left and right symmetrical; the two sides of the chute bracket 20 are respectively fixedly connected with the two ends of the two trunnions located in the rotating sleeve, and the chute is hung on the chute bracket, an...

Embodiment 2

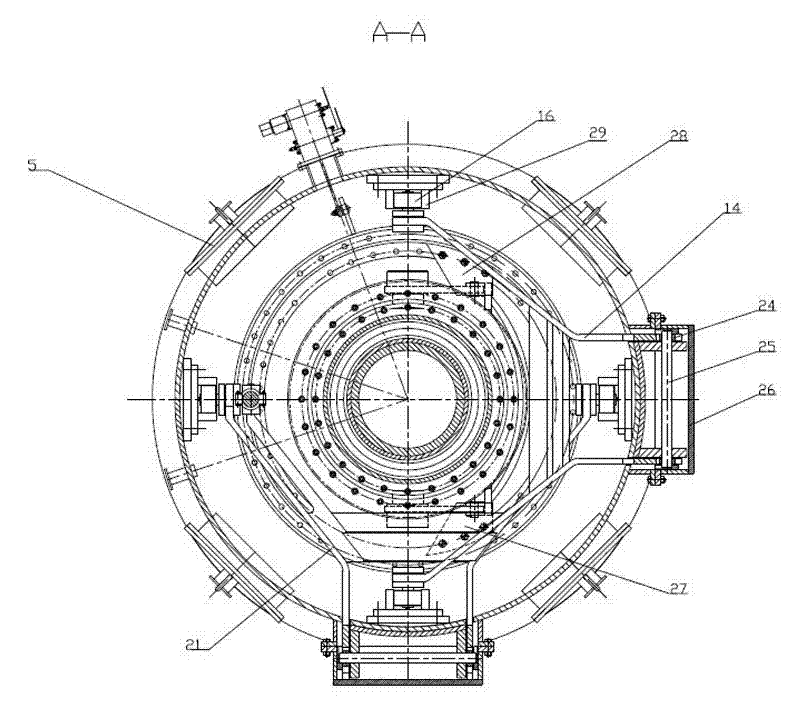

[0056] Embodiment 2: as Figure 9-16 As shown, the difference between this embodiment and Embodiment 1 lies in the supporting ring driving device. The supporting ring driving device in Embodiment 1 is provided with a set of hydraulic cylinders. In this embodiment, two sets of hydraulic cylinders are provided. The two sets of hydraulic cylinders Cylinders 12 are all vertically fixed on the top cover 9 of the distributor box, and the piston rod ends stretched into the distributor box are respectively hinged with the rigid drive arm 21; the rigid drive arm and the rigid balance arm The main function is to prevent the support ring from tilting during the up and down movement. In the actual application process, the two sets of rigid wishbone can be regarded as the anti-tilt mechanism. It can be applied to the existing distributor, and it can be combined with the existing single Arm double-link type or double-arm four-link type and other structural distributors are used together to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com