Prefabricated transverse H-shaped underground continuous wall joint section structure

A technology for underground diaphragm walls and joints, which is applied to underwater structures, infrastructure engineering, artificial islands, etc., can solve problems such as width exceeding the design width, quality accidents, and difficulty in verticality control, so as to ensure width and quality, save construction period and cost, and lengthen the effect of seepage bypass path

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

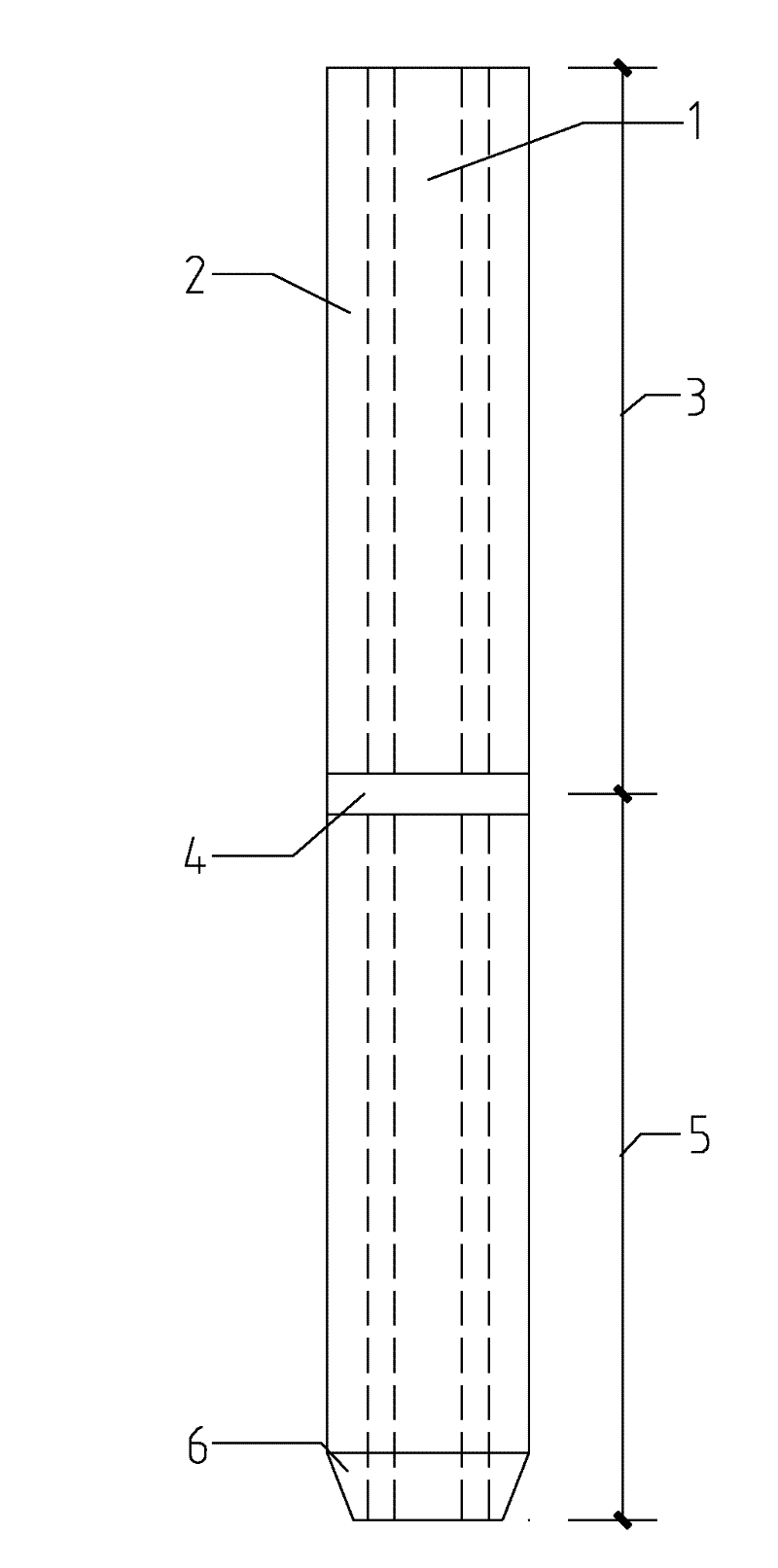

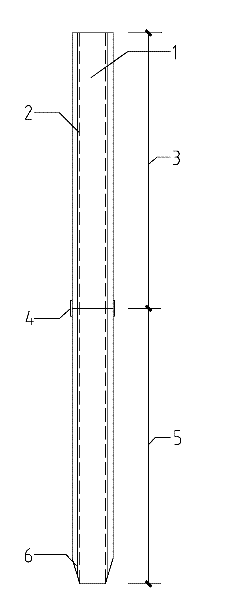

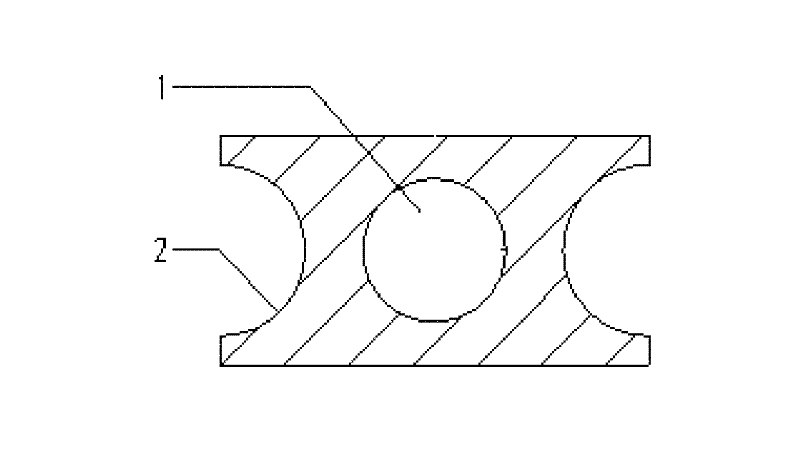

[0024] The joint section structure of the prefabricated I-shaped underground diaphragm wall of the present invention is described in conjunction with the accompanying drawings.

[0025] The structure of the joint section of the prefabricated I-shaped underground diaphragm wall of the present invention is: the two side ends of the cross section of the joint section are semicircular grooves 1, the middle part of the cross section of the joint section is a circular hole 2, and the joint section The section is divided into multiple length sections longitudinally, and a connecting steel plate is provided on the outside of the junction of every two length sections, and blade feet 6 are provided around the bottom of the joint section, and the length of the joint section is not less than 1500mm.

[0026] Such as Figure 1-a , Figure 1-b , figure 2 , image 3 As shown, the joint section structure of the prefabricated I-shaped underground diaphragm wall of the present invention, the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com