Spindle bearing of CT (Computed Tomography) machine

A main shaft bearing, integrated technology, applied in the direction of shaft and bearing, bearing, bearing components, etc., can solve the problems of difficult processing, high production cost, complex structure, etc., and achieve the effect of low processing difficulty, low production cost and long service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In conjunction with the accompanying drawings, the following embodiments of the present invention are given, but the present invention is not limited to the following embodiments.

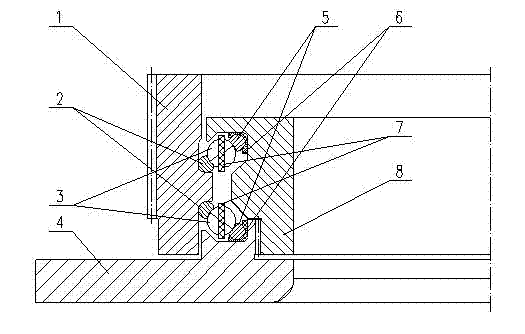

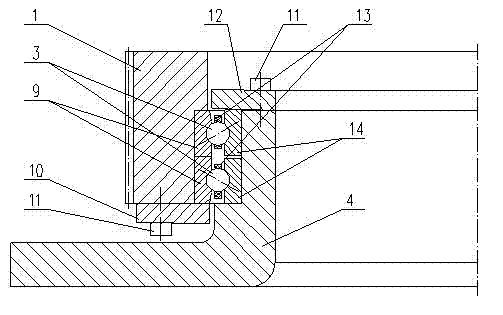

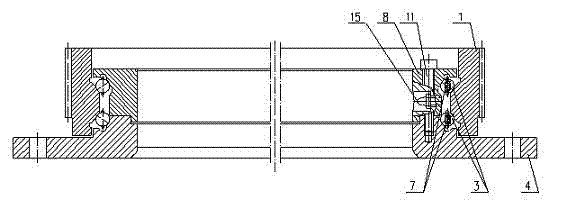

[0018] The CT machine spindle bearing described in this embodiment is a double-row angular contact ball slewing bearing, which is a radial bearing, made of surface hardened steel, and mainly bears the combined load of radial force and overturning moment. It includes an outer ring 1, an inner ring 4, a second inner ring 8, a second outer ring, steel balls 3, and a cage 7. The inner ring and the second inner ring form a combined inner ring, and the outer ring is toothed or not. There are two structures with teeth, the steel ball and the cage are installed between the combined inner ring and the outer ring; or the outer ring and the second outer ring form a combined outer ring, and the inner ring is toothed or not structure, the steel balls and the cage are installed between the combined outer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com