Four-side dust adsorption and easy cleaning workbench

A workbench, easy-to-clean technology, applied to workbenches, cleaning methods using gas flow, removal of smoke and dust, etc., can solve the problem of not using any dust-proof measures, and achieve the effect of preventing dust inhalation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

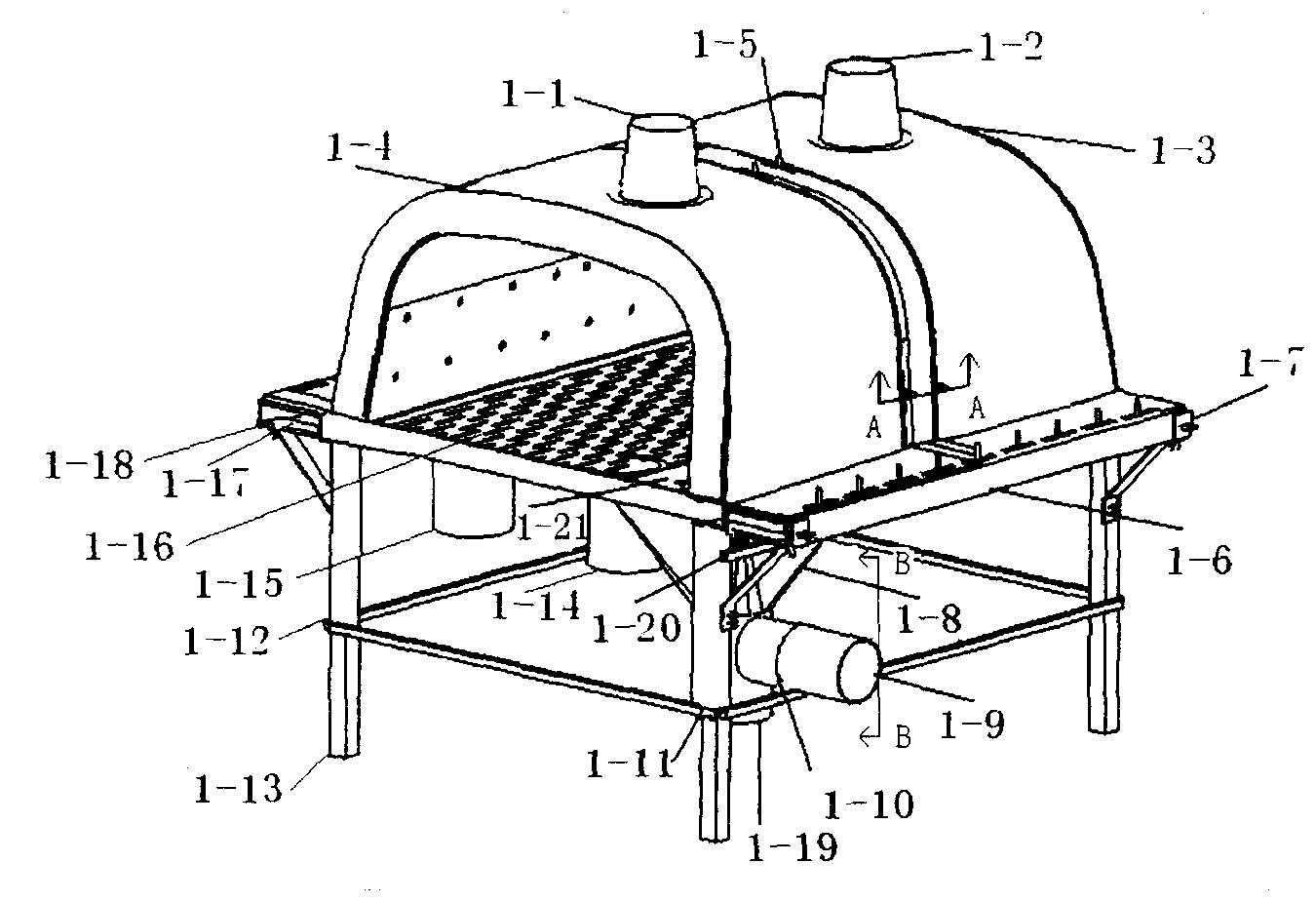

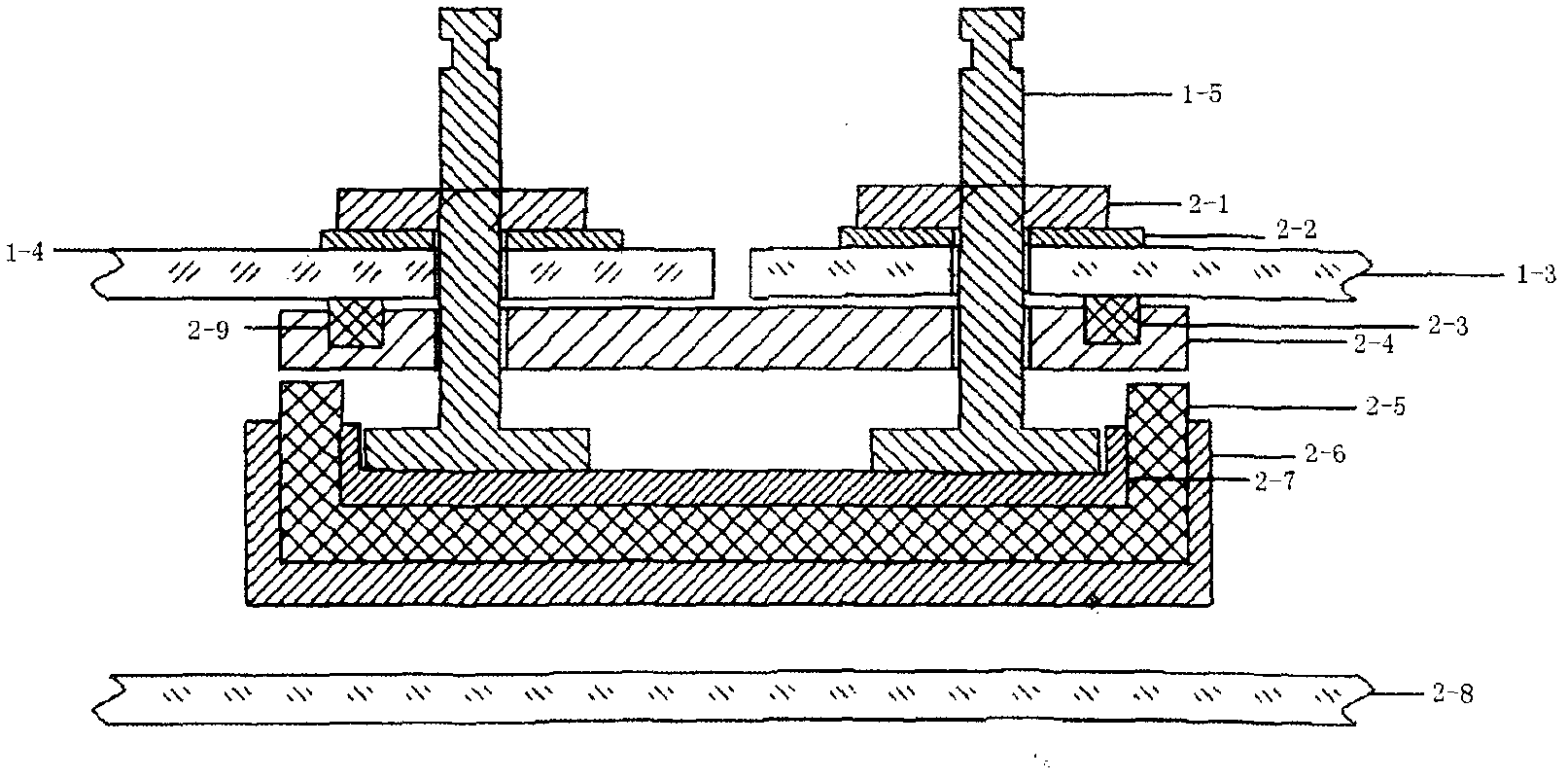

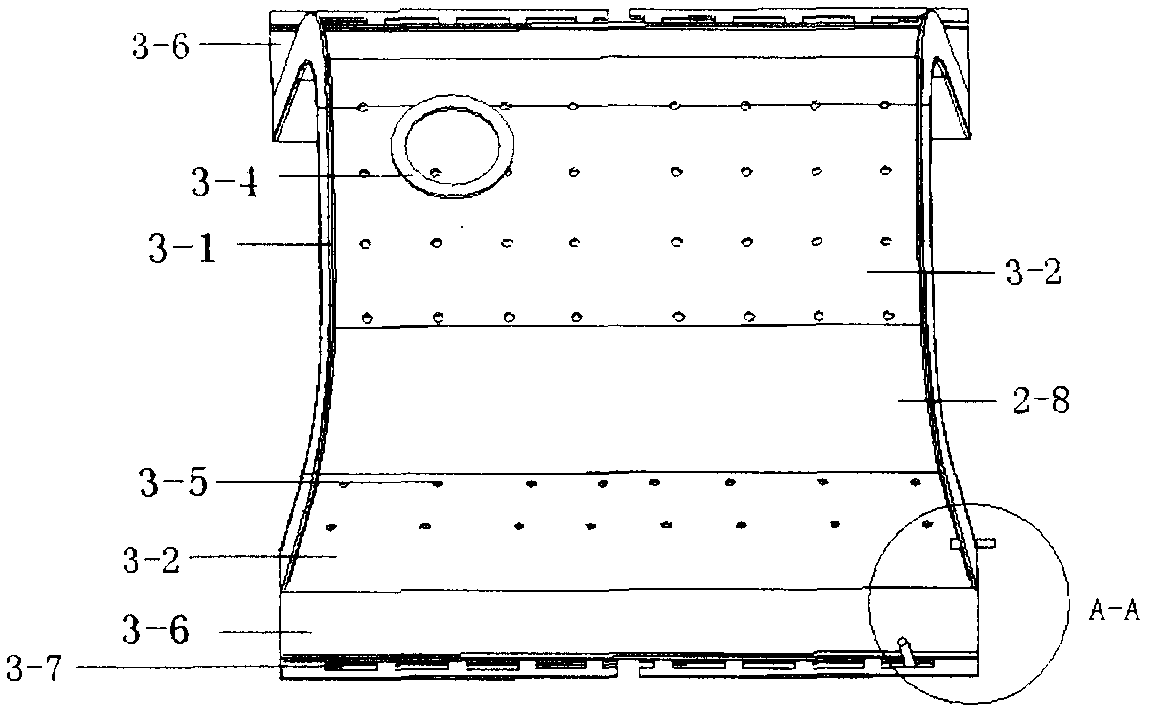

[0035] in figure 1 in

[0036] Workbench vertical supports (1-11) and workbench transverse supports (1-12) are installed at the upper third of the lower end of the workbench legs (1-13); the L-shaped connecting plate (1-7) is installed on the suction The side of the dust cover base (1-6); the table leg connecting plate (1-18) is installed under the workbench longitudinal beam (1-17), parallel to the workbench longitudinal beam (1-17), and installed in the work Opposite the longitudinal beam (1-17) is the crossbeam of the workbench, the connecting plate of the table leg (1-18) is installed under the crossbeam of the workbench, and the connecting plate (1-18) of the table leg is welded to the leg (1-13) ) Above; the bottom edge of the vacuum hood base (1-6) is seated on the table leg connecting plate (1-18), and the table leg connecting plate (1-18) bears the table longitudinal beam (1-17), The force above the beam of the workbench and the base (1-6) of the vacuum hood; the transp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com