An easy -to -clean workbench that absorbs dust on all sides

A workbench, easy-to-clean technology, applied in the direction of workbench, cleaning method using gas flow, dust removal, etc., can solve the problem of not using any dust prevention measures, and achieve the effect of preventing inhalation of dust

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

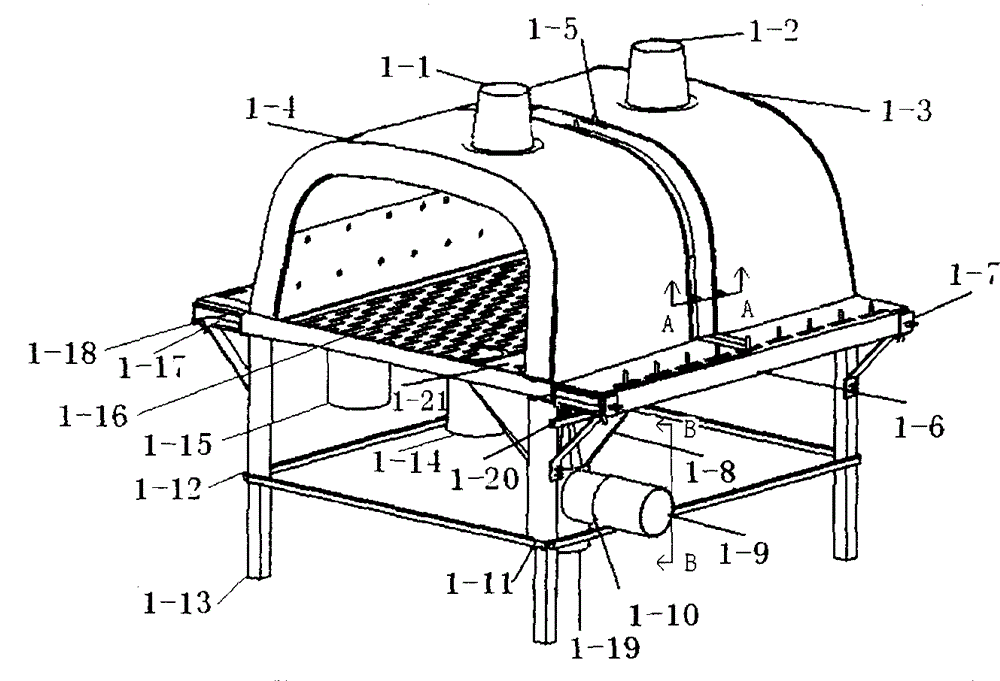

[0035] exist figure 1 middle

[0036] Workbench vertical support (1-11) and workbench cross brace (1-12) are installed on the upper third of the lower end of workbench leg (1-13); L-shaped connecting plate (1-7) is installed on the suction The side of the dust cover base (1-6); the table leg connecting plate (1-18) is contained in the following of the workbench longitudinal beam (1-17), is parallel with the workbench longitudinal beam (1-17), and is installed on the workbench longitudinal beam (1-17). Opposite the table longitudinal beam (1-17) is the workbench beam, the table leg connecting plate (1-18) is installed under the workbench beam, and the table leg connecting plate (1-18) is welded on the workbench leg (1-13 ) above; the bottom edge of the vacuum cover base (1-6) is located on the table leg connecting plate (1-18), and the table leg connecting plate (1-18) bears the workbench longitudinal beam (1-17), The force on the top of the workbench beam and the base of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com