Exterior skeleton type air bag clamping mechanical finger and clamping method

A technology of mechanical fingers and exoskeletons, applied in the directions of manipulators, chucks, manufacturing tools, etc., can solve the problems of high manufacturing cost, inability to form a manipulator, complex structure design, etc., and achieves convenient operation, easy to take and play workpieces, and simple structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

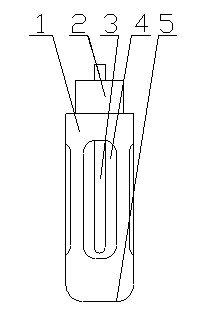

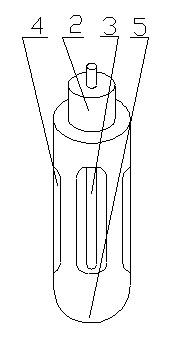

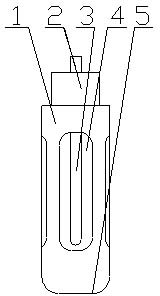

[0010] Embodiment 1: with reference to attached figure 1 and 2 . An exoskeleton-type airbag clamping mechanical finger, the finger skeleton 1 is a hollow tubular structure, and there are long holes 4 around the tube wall, one end of the hollow tube is arc-shaped closed or arc-shaped sealed structure 5, and the other end is connected to the The air nozzle 2 is connected, and the inner mouth of the air nozzle 2 communicates with the air inlet of the rubber air bag 3 located in the finger skeleton 1 . The making of finger frame 1, gas nozzle 2 and rubber air bag 3 is prior art, and is not described here. The finger skeleton 1 is rectangular or cylindrical. The finger frame 1 is made of metal or non-metal material. The inner side of the elongated hole 4 is inclined. The air nozzle 2 communicates with the electromagnetic intake and exhaust valve.

Embodiment 2

[0011] Embodiment 2: On the basis of Embodiment 1, a working method of exoskeleton-type airbag clamping mechanical fingers, located in finger skeleton 1 rubber airbag 3 air inlet is connected with gas nozzle 2, when the mechanical finger is required to work, control The actuator instructs the actuator to insert the finger skeleton 1 into the hole of the workpiece to be processed, the controller instructs the electromagnetic inlet and exhaust valve to close the exhaust valve port and open the air inlet port, and the pressurized gas in the air supply pipe is filled into the rubber air bag 3, The rubber airbag 3 inflates and expands from the long hole 4 around the finger skeleton 1 to touch the inner wall of the workpiece to be processed and move the workpiece to the processing tool. After processing, it moves to the designated workpiece stacking place. The intake and exhaust valves are opened, the electromagnetic intake valve is closed, the electromagnetic exhaust valve is opened...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com