Polyurethane elastomer fibers and processing agent and method therefor

一种聚氨酯类、弹性纤维的技术,应用在聚氨酯类弹性纤维用处理剂、聚氨酯类弹性纤维的处理以及聚氨酯类弹性纤维领域,能够解决得不到稳定操作性、卷装解舒性不好、平滑性或抗静电性不充分等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

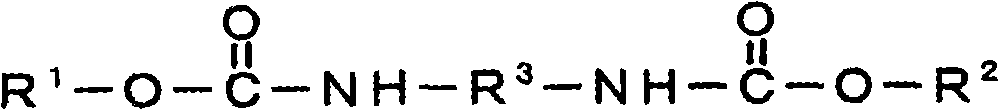

Method used

Image

Examples

Embodiment 1

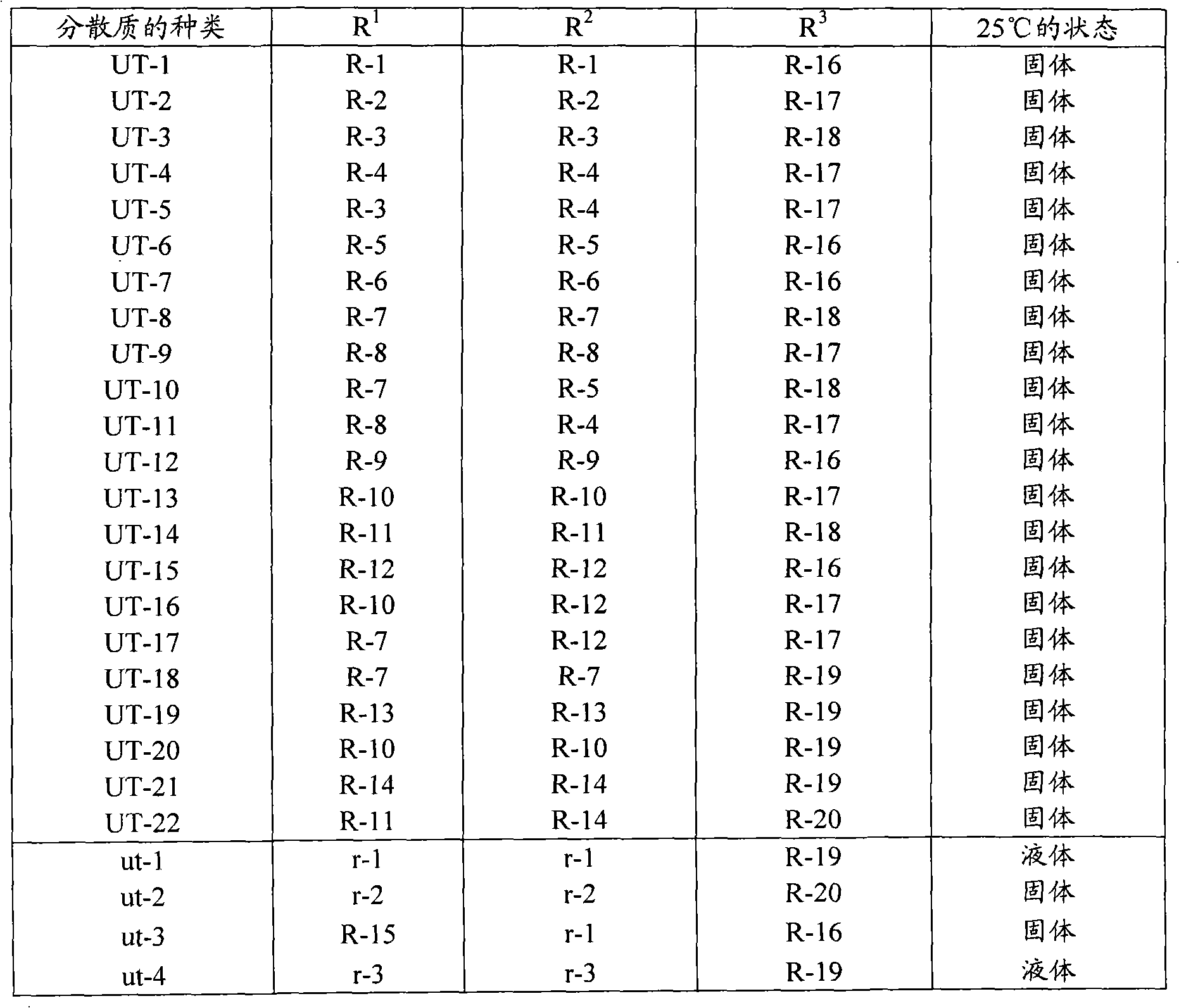

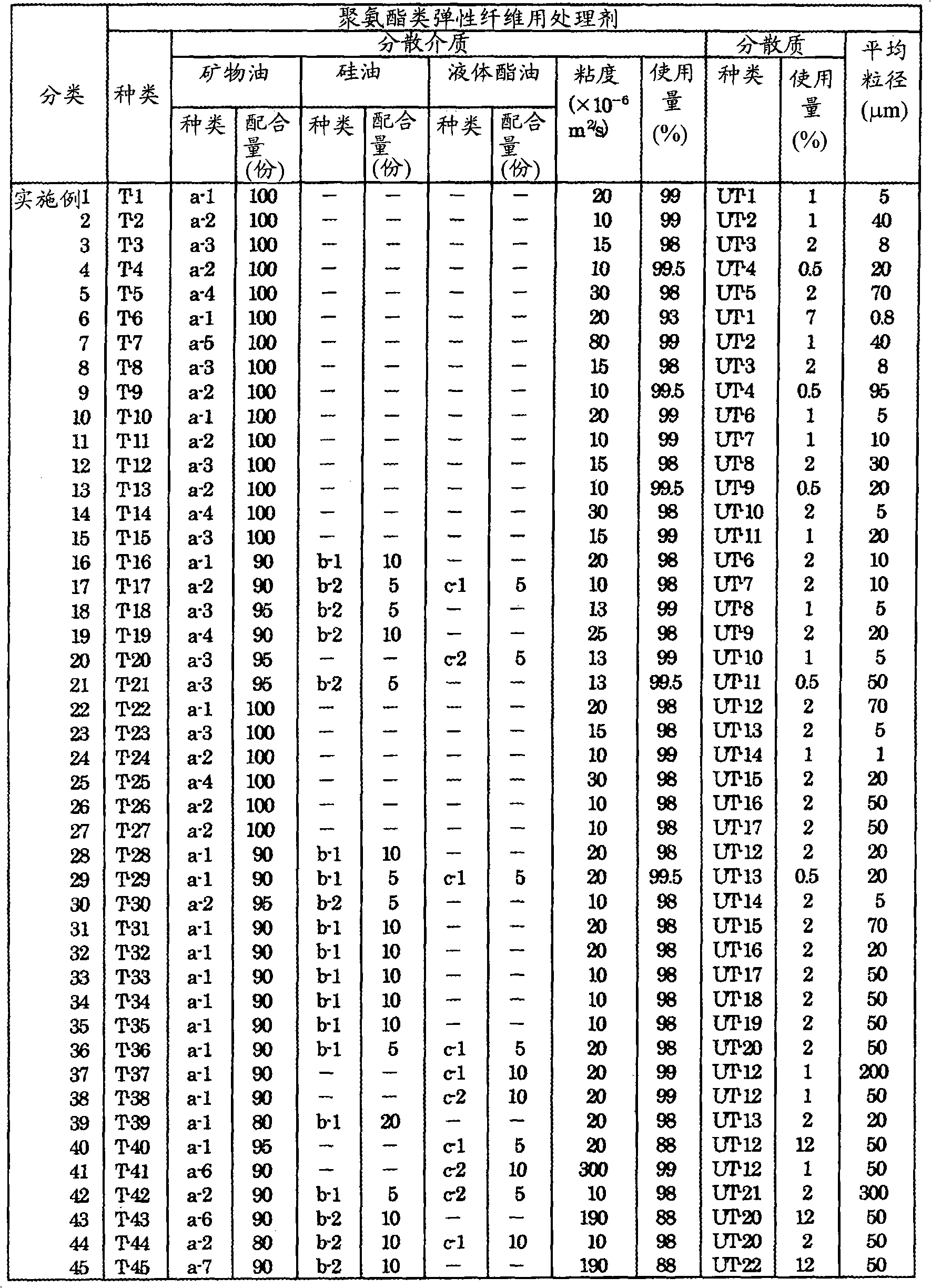

[0102] Example 1 {Preparation of treating agent (T-1) for polyurethane elastic fibers}

[0103] The viscosity at 25°C as the dispersion medium is 20×10 -6 m 2 99 parts of mineral oil (a-1) per s, and 1 part of urethane compound (UT-1) shown in Table 1 as a dispersant, mixed until uniform at a temperature of 20 to 35°C, and used A horizontal bead mill was used for wet pulverization to form a uniform dispersion, and the polyurethane-based elastic fiber treatment agent (T-1) corresponding to Example 1 having an average particle diameter of 5 μm obtained by the above average particle diameter measurement method was prepared.

[0104] ・Examples 2 to 15, 22 to 27 and Comparative Examples 2, 7, 9 to 12 {treatment agents for polyurethane elastic fibers (T-2) to (T-15), (T-22) to (T-27 ) and preparation of treatment agents for polyurethane elastic fibers (t-2), (t-7), (t-9) to (t-12) for comparison}

[0105] In the same manner as the treating agent for polyurethane elastic fibers (T...

Embodiment 16

[0106] Example 16 {Preparation of treating agent (T-16) for polyurethane elastic fibers}

[0107] The viscosity at 25°C as the dispersion medium is 20×10 -6 m 2 The viscosity of 90 parts of mineral oil (a-1) per s and 25°C is 20×10 -6 m 2 / s of 98 parts of a mixture of 10 parts of polydimethylsiloxane (b-1) and 2 parts of urethane compound (UT-6) shown in Table 1 as a dispersoid at 20 to 35°C After mixing at a uniform temperature, use a horizontal bead mill to perform wet pulverization to form a uniform dispersion, and prepare a polyurethane elastic fiber equivalent to Example 16 with an average particle diameter of 10 μm obtained by the above-mentioned method for measuring the average particle diameter. Treatment agent (T-16).

[0108] ・Examples 18, 19, 21, 28, 30 to 35, 43 and Comparative Examples 1, 3, 4 {Treatment agent for polyurethane elastic fibers (T-18), (T-19), (T-21), (T-28), (T-30) to (T-35), (T-43) and the treatment agents for polyurethane elastic fibers (t-1...

Embodiment 17

[0110] Example 17 {Preparation of treating agent (T-17) for polyurethane elastic fibers}

[0111] The viscosity at 25°C as the dispersion medium is 10×10 -6 m 2 The viscosity of 90 parts of mineral oil (a-2) per s at 25°C is 10×10 -6 m 2 / s 98 parts of a mixture of 5 parts of polydimethylsiloxane (b-2) and 5 parts of isotridecyl stearate (c-1), and the amino group shown in Table 1 as a dispersoid After mixing 2 parts of formate compound (UT-7) at a temperature of 20 to 35°C until uniform, wet pulverization was carried out using a horizontal bead mill to form a uniform dispersion, and prepared by the above-mentioned method for measuring the average particle size. The processing agent (T-17) for polyurethane elastic fibers corresponding to Example 17 whose average particle diameter is 10 micrometers.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com